Automobile clothes tree folding structure and manufacturing method thereof

A technology for coat racks and automobiles, which is applied to chemical instruments and methods, rack configuration, lamination devices, etc., can solve the problems of complex production and molding process, inconvenience and trouble for users, and achieves the improvement of practicability and durability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

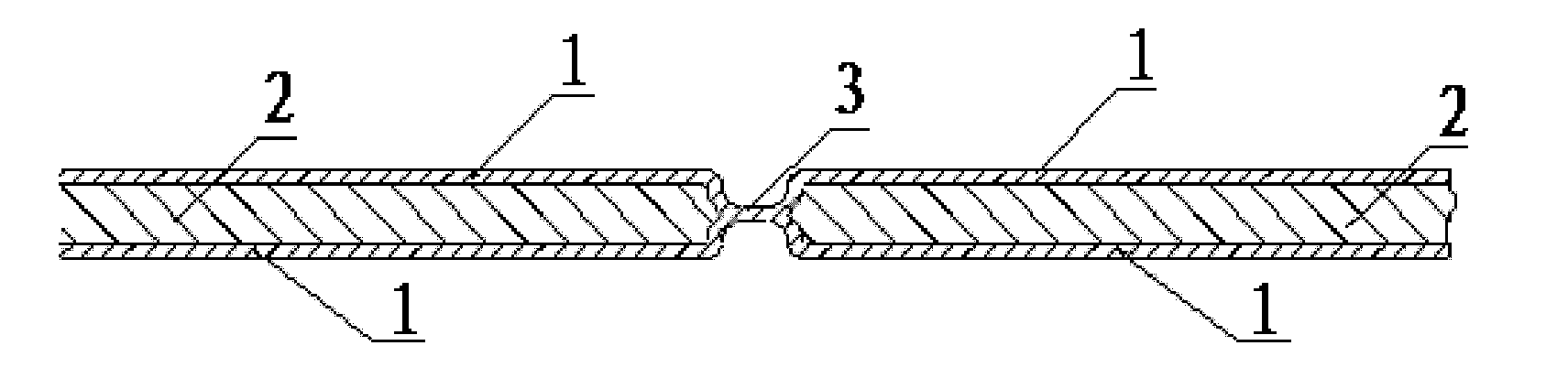

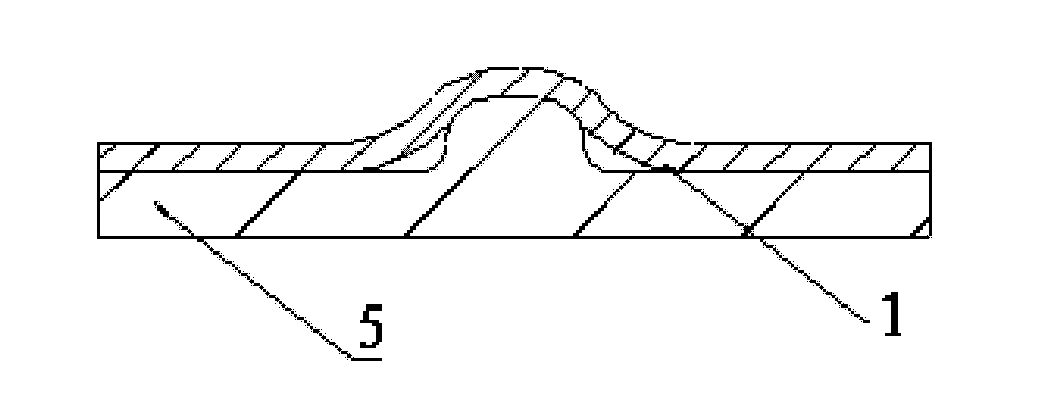

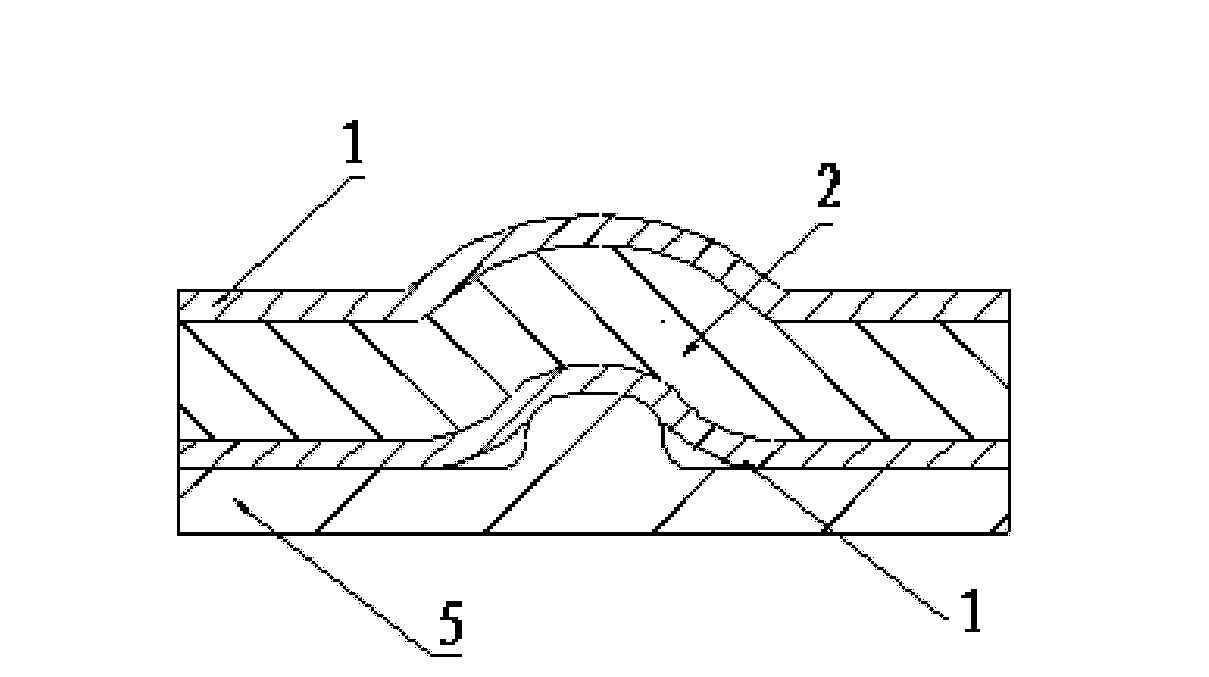

[0019] see figure 1 It can be seen that the coat rack plate is composed of upper and lower layers of surface fabric 1 and the middle body substrate 2. The surface fabric 1 is usually industrial non-woven fabric, more specifically polymer long-fiber non-woven fabric. One layer of surface fabric 1 is the upper surface fabric 1, which faces upwards and is the side that consumers use and often sees. Therefore, the material is relatively better. There is also a layer of lower surface fabric 1, which faces the car floor and is very useful. surface, so the material can be relatively poor, which has saved manufacturing costs. The main body substrate 2 is usually a high molecular polymer wood flour board, and contains modified additive materials, so as to ensure that the coat rack has a certain degree of toughness and flexibility.

[0020] The coat hanger has a straight and long fold mark 3 at the part that needs to be folded. This part has a depression formed when the product is mold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com