Shading tool for vehicle driving

A technology of tools and visors, which is applied to vehicle parts, anti-glare equipment, transportation and packaging, etc., can solve the problems of drivers' vision loss, mental stress, and unfavorable safety of passing cars and pedestrians, etc., and achieves wide application, simple structure, Ease of promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The motor described in Example 1 is a positive and negative motor, and the electric lifting device adopts a bamboo-type lifting method, taking a three-section spiral synchronous lifting as an example.

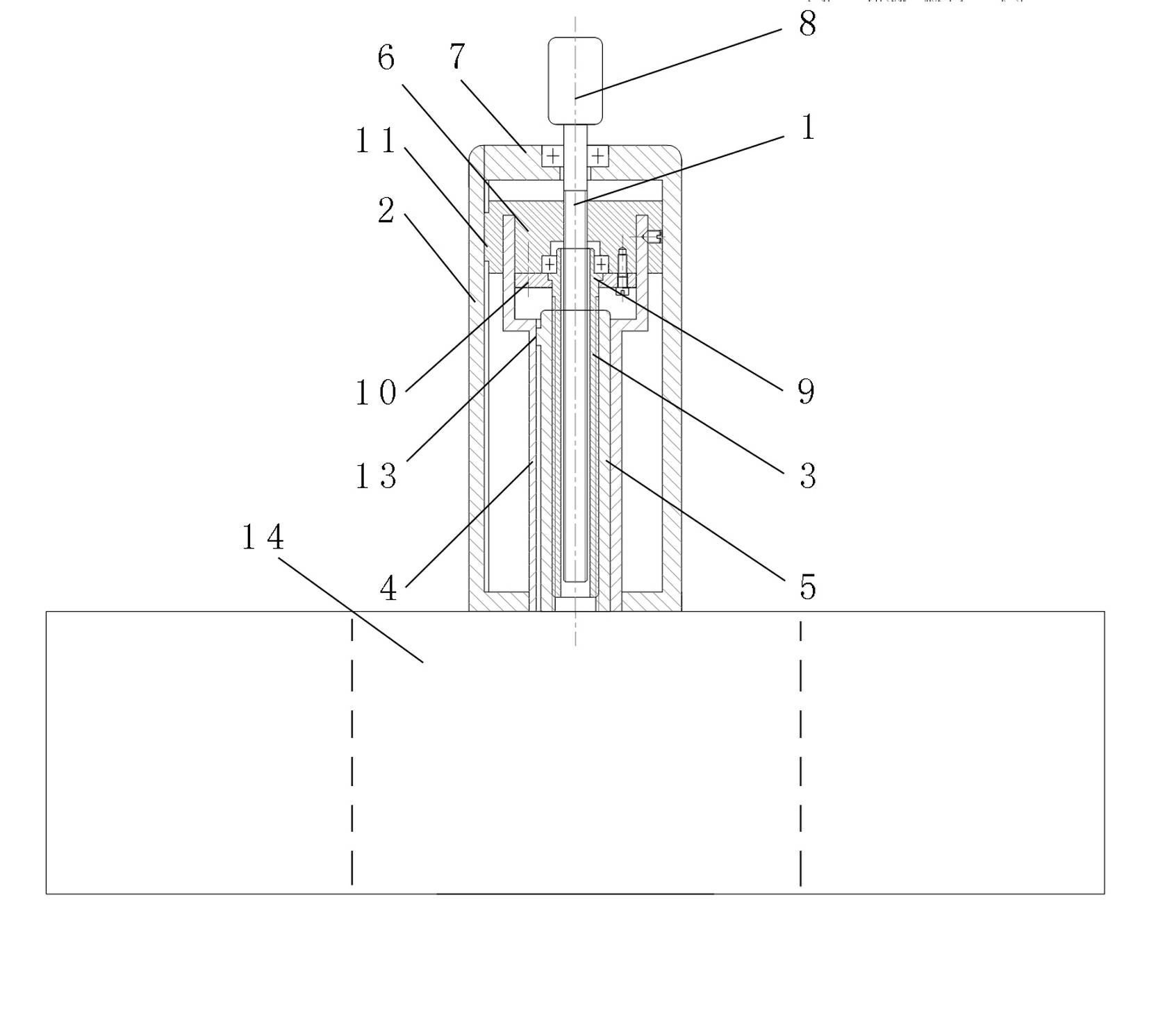

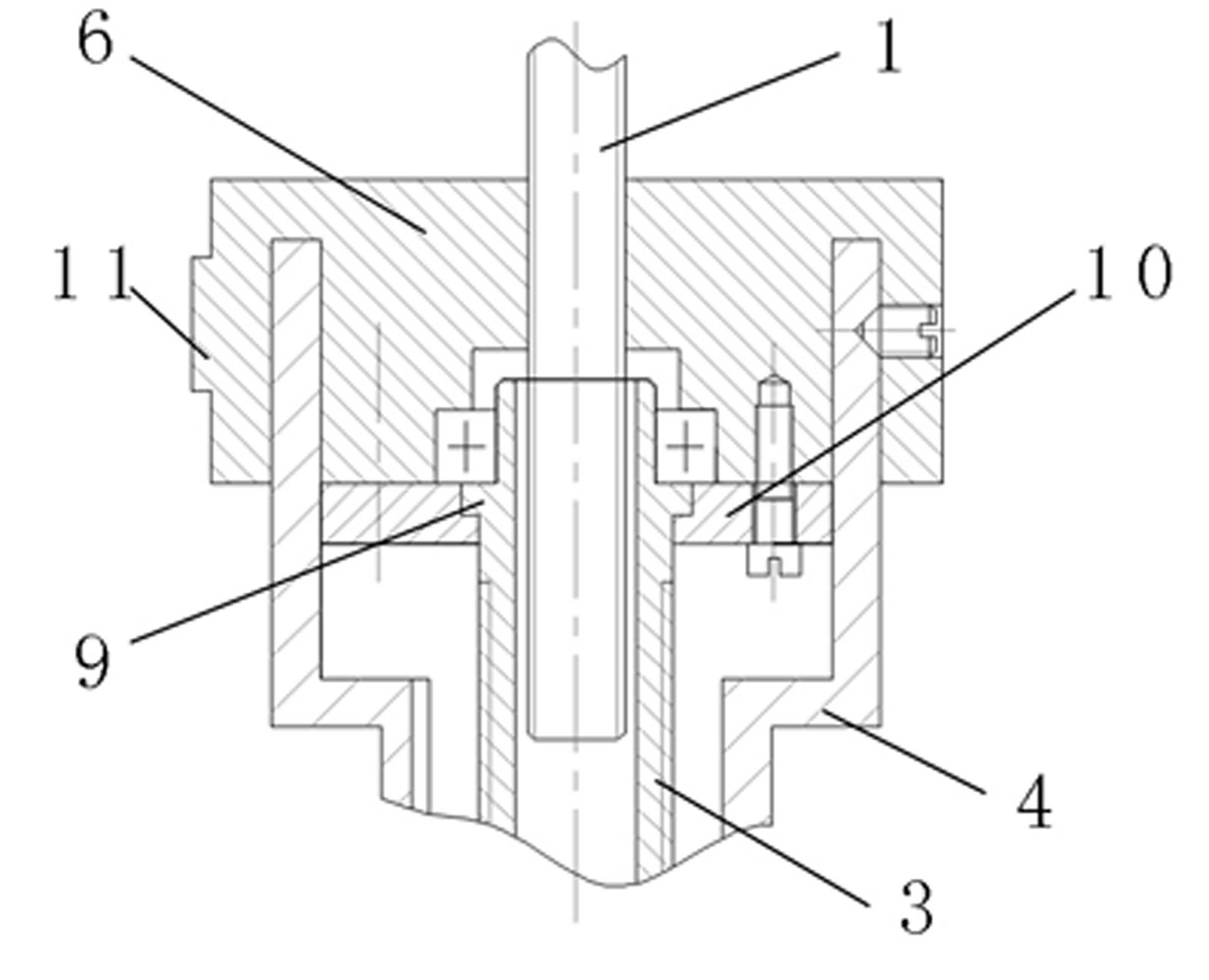

[0028] Such as figure 1 , 2 As shown, the electric lifting device includes a primary active screw 1 and a primary lever body 2 , a secondary lever tray 6 , a secondary active screw 3 , a secondary lever body 4 , and a tertiary lever body 5 . The first-level bar body 2, the second-level bar body 4 and the third-level bar body 5 form a casing sleeve, and the third-level bar body 5 in the innermost layer of the casing pipe is the jacking pipe. The first-level active screw 1 is installed in the first-level lever body 2, the first-level lever body 2 is installed on the base 7, the polished rod part of the first-level active screw 1 is connected with the base 7 through a bearing, and the first-level active screw The power input end 8 of 1 is exposed outside the base 7 and is...

Embodiment 2

[0036] Embodiment 2 adopts the lifting mode step by step step by step. Such as Figure 7 As shown, Embodiment 2 includes a housing 15 , a motor 16 , an electric lifting device and a shade 14 . There is an opening below the housing 15 .

[0037]The electric lifting device includes a multi-segment bushing, and a steel tie bar 17 with a clamping hole, a disc spring 18 and a power input gear 19 installed in the housing 15 . The locking teeth of the power input gear 19 are engaged with the locking holes on the steel stays 17 . The purpose of the disc spring 18 is to tension the steel brace 17 against free expansion. The outermost layer of the multi-section casing is the bottom pipe 20, and the bottom pipe 20 is fixedly installed at the opening below the casing 15. The innermost layer of the casing is the top pipe 21, and the end of the top pipe 21 is fixed with a connection device, the connecting device is connected to the light shielding plate 14 (blocked by the light shieldin...

Embodiment 3

[0041] In addition to the structure in embodiment 1, embodiment 3 also includes a light control switch connected to the motor circuit, and the light control switch includes an external electronic photosensitive head connected to the circuit, a signal conversion circuit, an amplification circuit and a PLC controller . The optical signal collected by the external electronic photosensitive head is converted into an electrical signal by the signal conversion circuit, and then transmitted to the PLC controller set in the circuit after being amplified by the amplifier in the amplification circuit, and the PLC controller controls the motor to rotate forward or reverse. change. The PLC controller of the light control switch under strong light makes the motor rotate forward, and the sun visor 14 is lowered;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com