Cooling jacket for double-wall corrugated pipe

A double-wall corrugated tube and cooling jacket technology, applied in the field of cooling jackets, can solve the problems of increased equipment cost, uneven inner surface quality, uneven cooling, etc., to improve cooling effect and efficiency, ensure product quality uniformity, and achieve good environmental protection. Effects of stiffness and ring compliance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

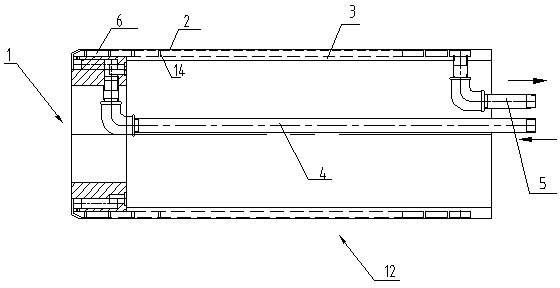

[0020] The advantages of the present invention will become clear and easier to understand by describing the embodiments with the accompanying drawings.

[0021] as attached figure 1 As shown, the cooling jacket of the double-wall corrugated pipe includes a body 12 and a distributor 1 installed at one end of the body 12. The outer jacket 2, the distributor 1 is connected with a coolant inlet pipe 4, and the other end of the body 12 is equipped with a coolant outlet pipe 5, and a cooling cavity for cooling liquid flow is formed between the outer jacket 2 and the inner jacket 3, The liquid outlet pipe 5 communicates with the cooling chamber. The cooling liquid enters the distributor 1 through the liquid inlet pipe 4, and the distributor 1 makes the cooling liquid evenly disperse in the circumferential direction, enters the cooling chamber, and finally flows out through the liquid outlet pipe 5.

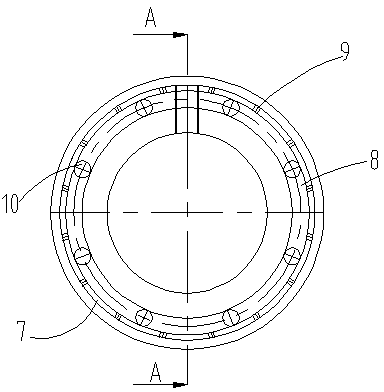

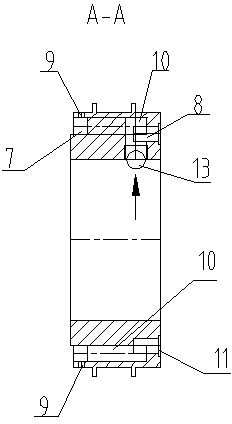

[0022] as attached figure 2 , attached image 3 As shown, a coolant inl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com