Lock-attachment rotary platform

A rotary table and locking technology, which is applied to workbenches, hand-held tools, manufacturing tools, etc., can solve problems such as laborious operation, and achieve the effects of convenient use, simple structure and improved work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

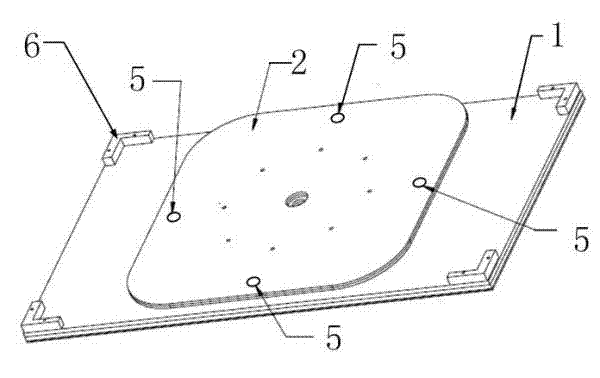

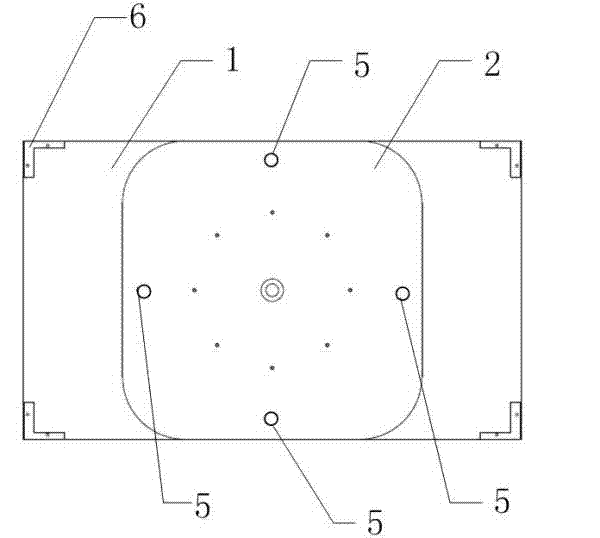

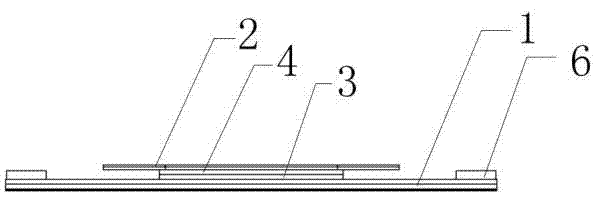

[0016] A kind of locking rotary table of this embodiment, such as Figure 1 ~ Figure 3 As shown, it includes a workbench 1 and a base 2, the center of the lower surface of the workbench 1 is fixedly connected to the upper ring groove block 3, and the center of the upper surface of the base 2 is fixedly connected to the lower ring groove block 4 corresponding to the upper ring groove block 3, Between the upper ring groove block 3 and the lower ring groove block 4 are provided balls to make the table 1 rotate relative to the base 2 . Four main magnetic blocks 5 are arranged on the base 2, and the main magnetic blocks 5 are distributed on the same circular arc centered on the rotating shaft of the worktable 1, and the two adjacent main magnetic blocks 5 form a 90-degree angle ; Workbench 1 is equipped with secondary magnetic blocks corresponding to the main magnetic block 5 and opposite to each other. L-shaped support blocks 6 are respectively installed at the corners of the fou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com