Organic flat tea (Houkui) and preparation technique thereof

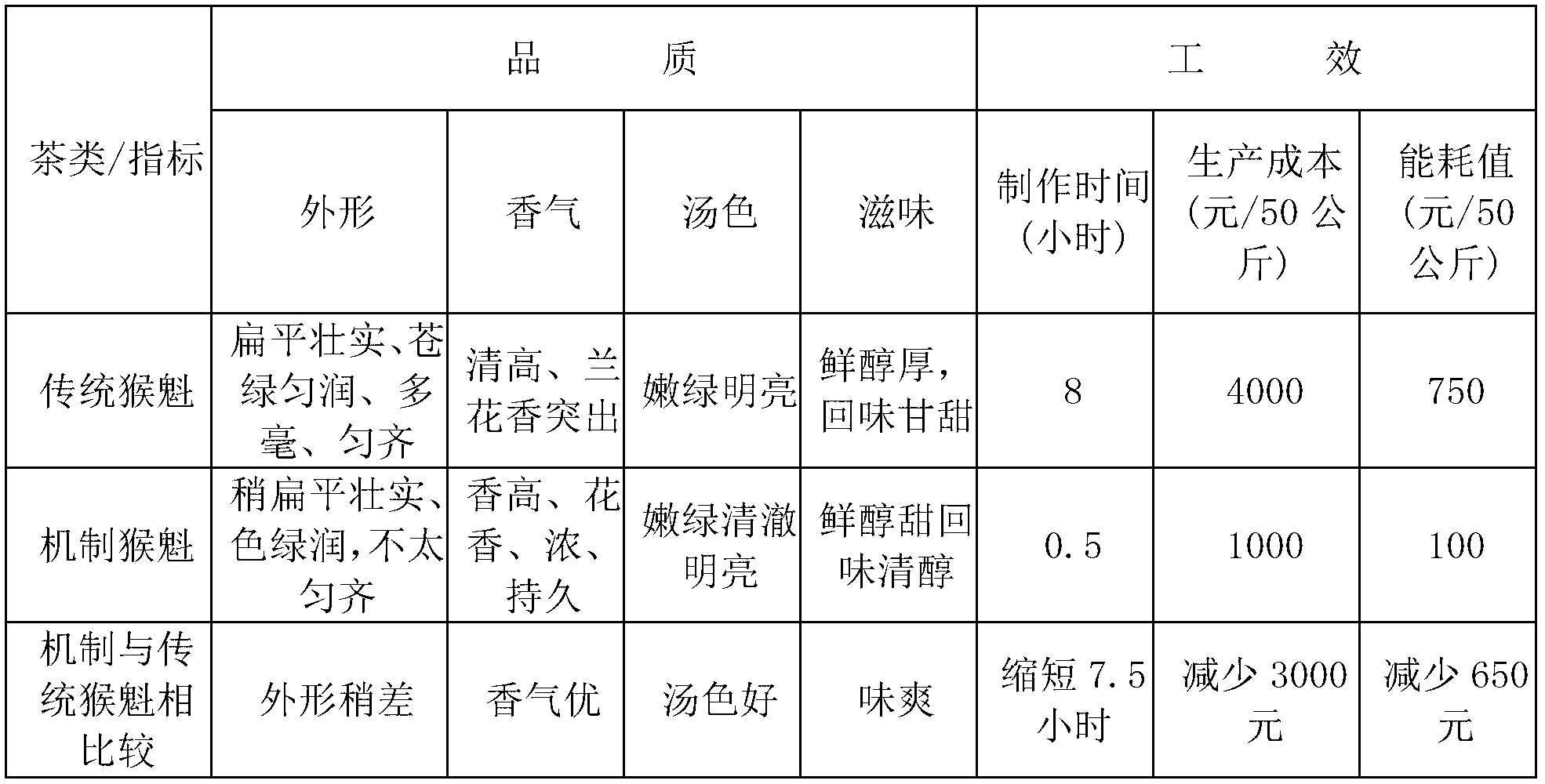

A production process and flat tea technology, which is applied in the field of flat tea (houkui tea) production technology to achieve the effects of short production time, high work efficiency, low energy consumption value and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

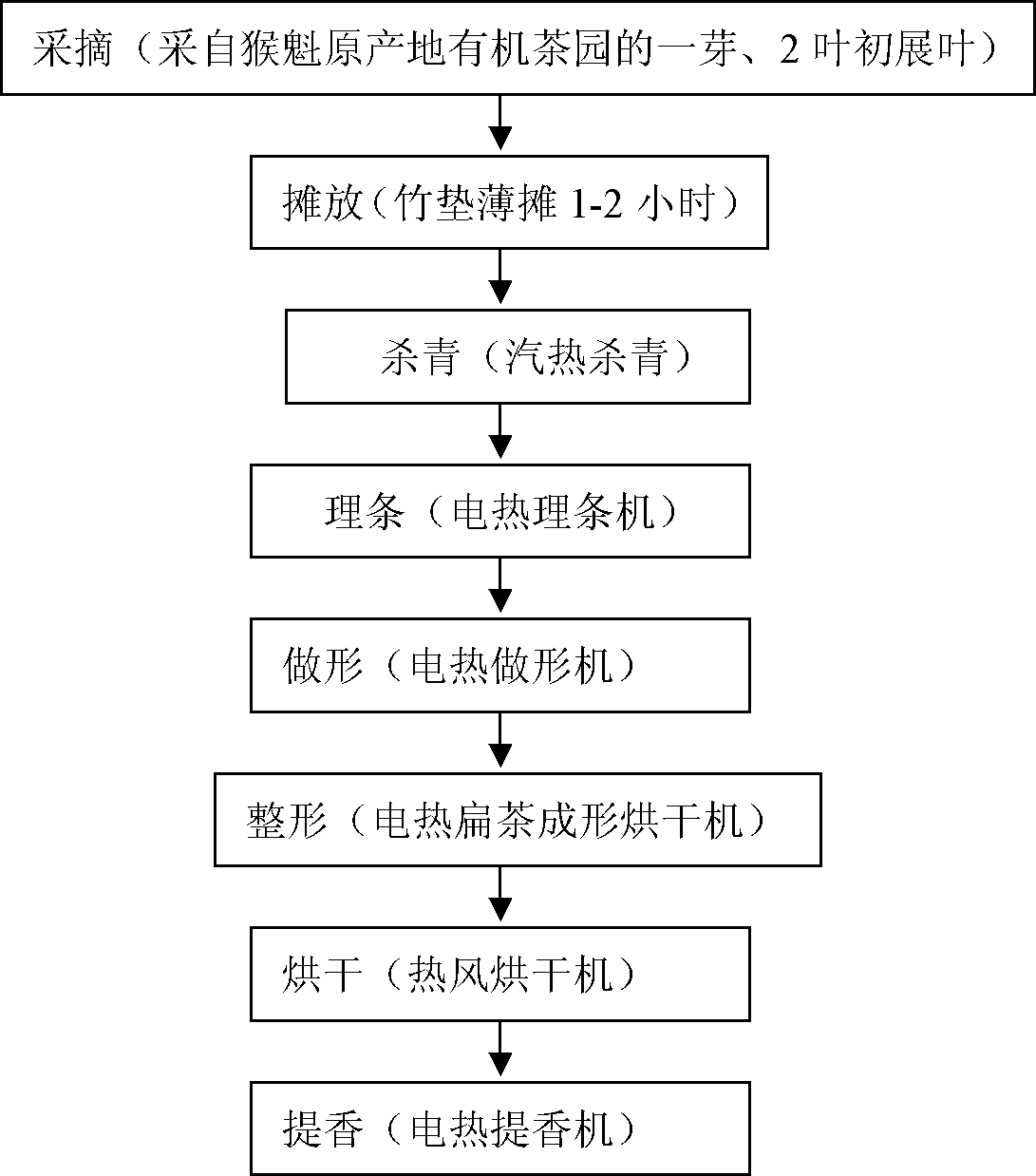

[0054] Embodiment 1: Production process of mechanism flat Houkui tea spring tea

[0055] The spring tea picked from the organic tea base should be placed on a bamboo mat and spread for about 1-2 hours. Due to the high water and humidity in spring, the spreading time should be extended, which is conducive to the distribution of "surface water" and "grass gas" of the tea. , At this time, the finishing temperature should be slightly higher, and it should be controlled at about 220°C. If the temperature is too low, it will be difficult to kill the tea leaves evenly. The strip temperature is 140-150°C, and the time is 9-10 minutes. When shaping, because the water content in the tea leaves is slightly higher, the pressure of the shaping wheel can be increased to facilitate shaping. Simultaneously, the forming temperature is correspondingly increased to between 140-150°C, and the time is extended to 7-8 minutes. The shaping temperature is 125-130°C, and the time is 9-10 minutes. T...

Embodiment 2

[0056] Embodiment 2, the production process of mechanism flat Houkui Xia tea

[0057] In summer, due to the high temperature and dryness, there is a certain difference in the production process compared with spring tea. When the fresh leaves are harvested, they are immediately placed on a bamboo mat for about 1-2 hours, with a thickness of about 1 cm, and blow cold wind to cool down. , so as not to produce redness. When finishing, adjust the conveyor belt to the fast gear, adjust the finishing temperature to about 200°C, and shorten the time to 3-4 minutes. If the temperature is too high, it will dry out after a long time. The strip temperature drops by 120-130°C, and the time is reduced to 9-10 minutes. When shaping, "three drops" should be carried out. First, the pressure of the shaping wheel should be adjusted to the minimum. Second, the shaping time should be shortened to 7-8 minutes. Third, the shaping temperature should also be reduced to 110-120°C to avoid Because the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com