Automatic assembling work head device of curved-surface magnet of voice coil motor

An automatic assembly, voice coil motor technology, applied in the direction of electromechanical devices, electric components, manufacturing motor generators, etc., can solve the problems of low efficiency of manual assembly, difficult to guarantee quality, etc., to eliminate unstable factors, save labor, and reduce production. cost effect

Inactive Publication Date: 2012-06-13

ZHEJIANG UNIV

View PDF5 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In order to solve the problems of low manual assembly efficiency and difficult quality assurance of curved surface magnets of voice coil motors, the invention provides a working head device for automatic assembly of curved surface magnets of voice coil motors

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

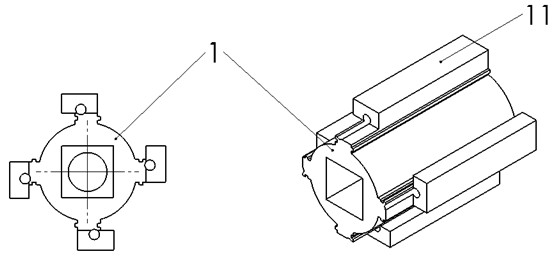

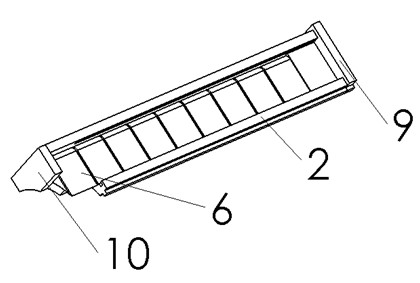

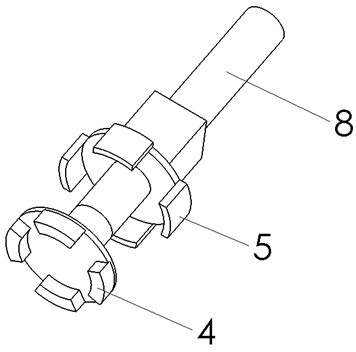

The invention discloses an automatic assembling work head device of a curved-surface magnet of a voice coil motor. The device comprises: an automatic feed warehouse, an outbound warehouse positioning device formed by a rotation adsorption magnet and a built-in baffle plate, a push-rod blanking mechanism and a non-magnetic shell. The feed warehouse is uniformly embedded around the shell. The push-rod blanking mechanism is fixed at a position which has an interval of a specific angle with the feed warehouse. The outbound warehouse positioning device is located under the shell and a rotating shaft passes through a central section of the shell and is connected with the external motor. Batch magnets are loaded into the automatic feed warehouse before magnetization and after the magnetization, the magnets mutually generate an expulsive force. A rotation adsorption magnet drives the magnet to be assembled on an exit on a lower part of the feed warehouse to be separated from the warehouse and be positioned. The residual magnets automatically feed under common effects of a gravity and a magnetic force. The push-rod blanking mechanism pushes the positioned magnets into the voice coil motor shell so as to complete the assembling. According to the invention, batch magnetization of the voice coil motor magnets and continuously automatic assembling can be realized. Production efficiency of the voice coil motor can be increased. Artificial cost can be reduced and product quality can be guaranteed.

Description

technical field The patent of the present invention relates to an automatic assembly device for a voice coil motor magnet, in particular to an automatic assembly head for a voice coil motor magnet with a curved surface and a feeding device thereof. Background technique Voice Coil Motor (Voice Coil Motor, VCM, also known as moving coil permanent magnet linear motor) is a new type of micro motor that directly converts electrical energy into linear motion mechanical energy without any intermediate conversion mechanism. Due to its small size and weight Lightweight, high frequency response, good dynamic performance, precise positioning, convenient control, etc., are widely used in high-tech fields such as national defense, aerospace, and IT. The magnets distributed around the casing are responsible for providing a uniform air gap magnetic field, which is a key part of the voice coil motor. However, due to the interaction between the magnets and the curved surface, separation an...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H02K15/00

Inventor 邬义杰王彬沙钊吴星星

Owner ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com