PH (Potential of Hydrogen) control system and application thereof

A technology of control system and control device, applied in the direction of control/regulation system, ratio control, chemical variable control, etc., can solve the problems to be improved, and achieve the effect of improving efficiency and effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

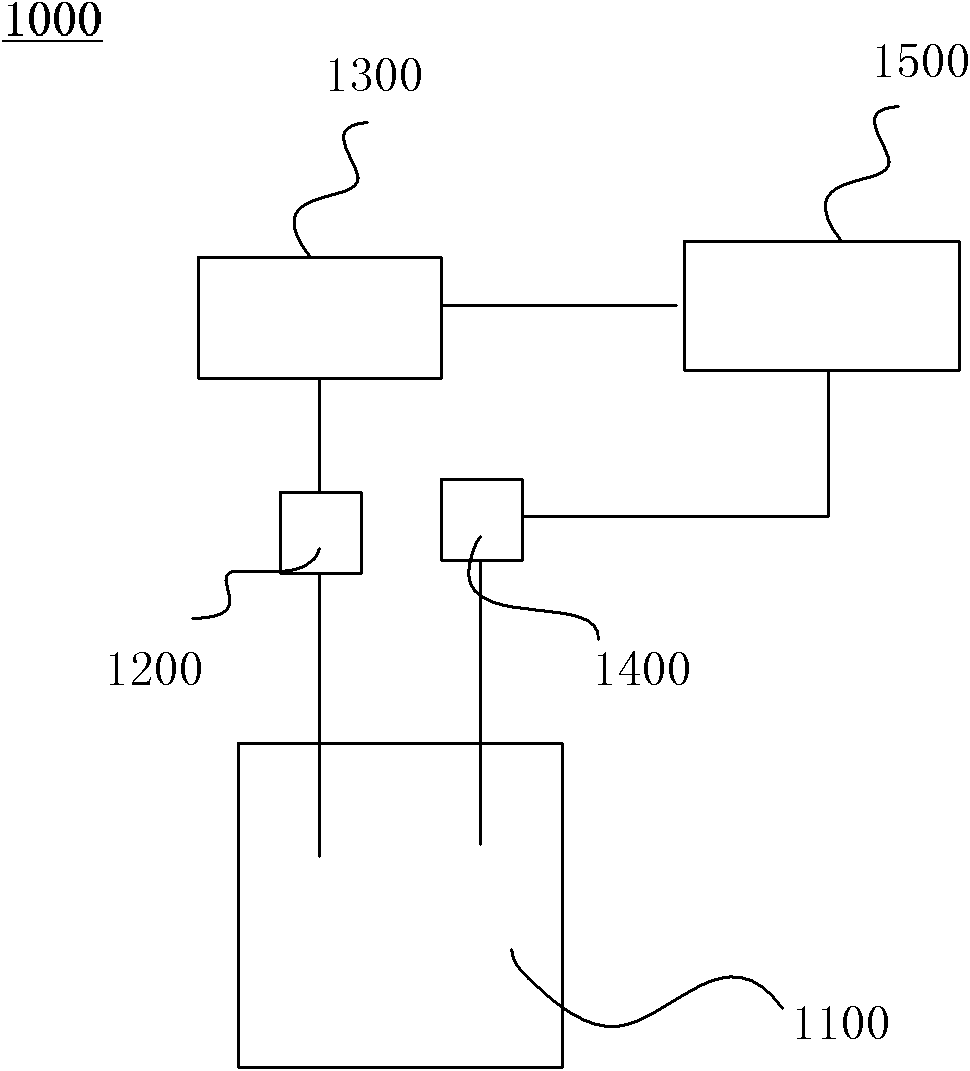

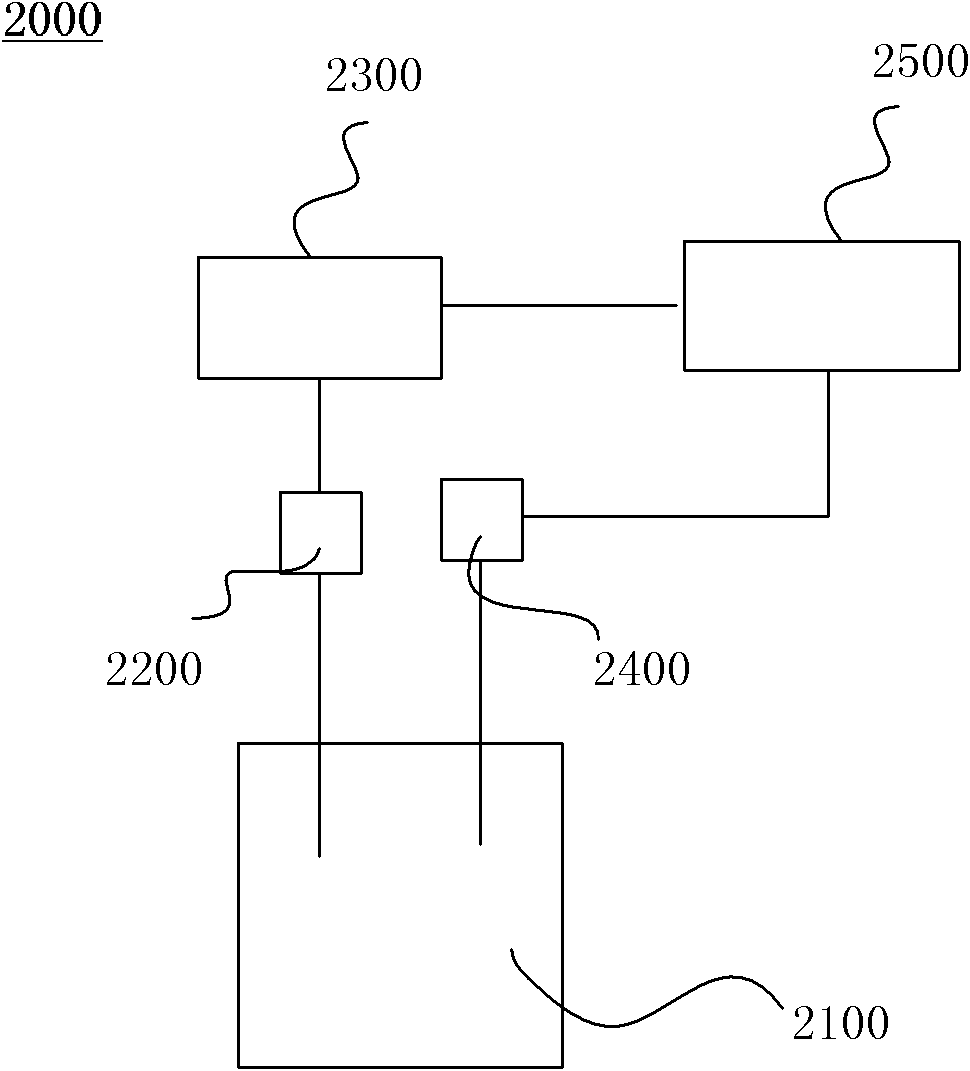

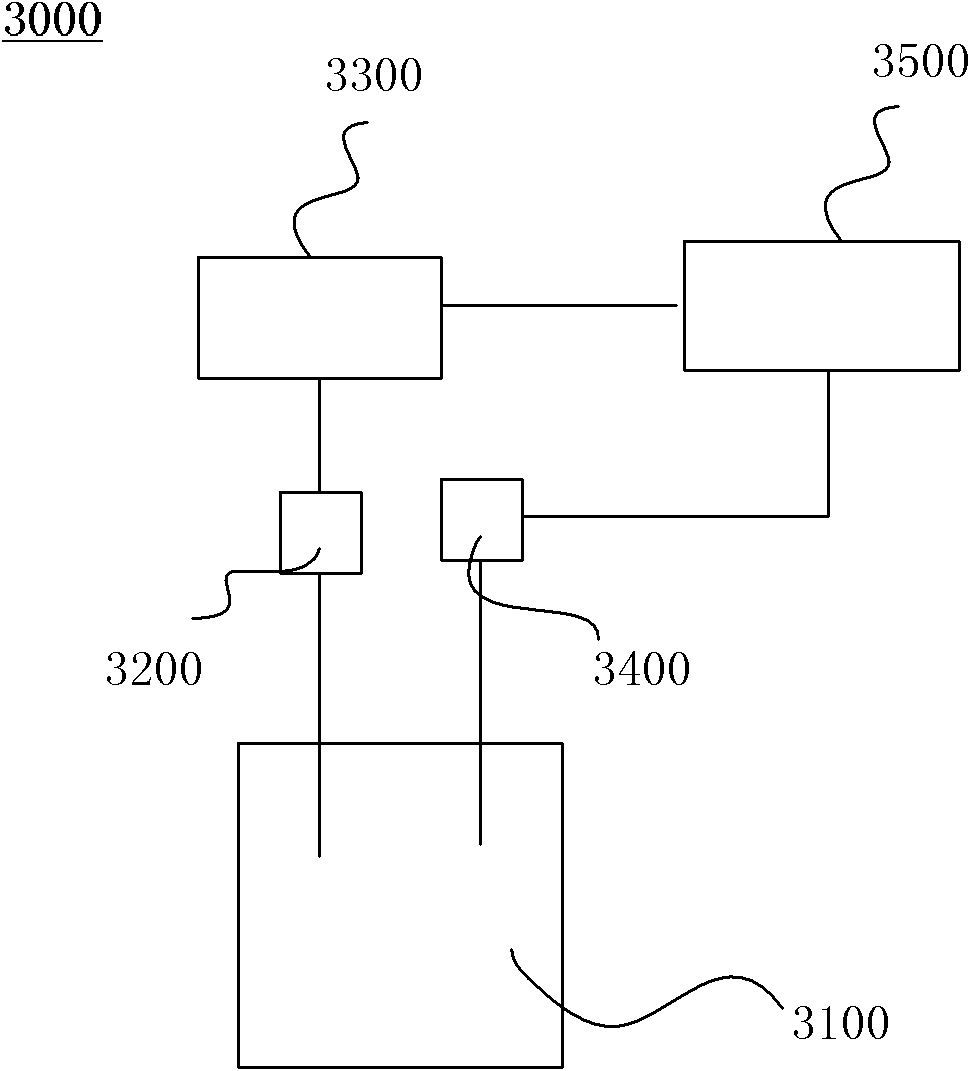

[0105] refer to Figure 5-8, provides a method for automatic detection and control of the concentration of the metal coating pretreatment tank solution: a monitoring system composed of an upper industrial computer, a display screen and configuration software; a control system composed of a PLC and a touch screen; and the detection and feeding of each tank solution A method for automatic detection and control of the concentration of the metal coating pretreatment bath liquid composed of sub-systems of the device. Use the online free alkalinity automatic detection device to detect the pre-degreasing bath liquid containing alkali degreasing agent in metal pretreatment, and the free alkalinity of the degreasing bath liquid, and use the online pH automatic detection device to convert the film containing nano-ceramic conversion agent or silane treatment agent The method of detecting the water quality of the cleaning tank through the online automatic conductivity detection device, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com