Method for evaluating rutting resistance of asphalt pavement structure

A technology of asphalt surface layer and evaluation method, which is applied in the direction of testing the strength of materials by applying repetitive force/pulse force, which can solve the problem of difficulty in ensuring the anti-rutting performance of pavement structures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] The initial surface layer structure of an uphill section of an expressway is

[0052]4.5cmSMA-16+5.5cmAC-20+6cmAC-25. The proportion of heavy-duty vehicles on the original road surface is relatively large. After six months of opening to traffic, serious rutting occurred on the uphill section; later, the original road surface was milled and then re-paved. The road surface structure after treatment was 4.5cmFAC-13+5.5cm FAC-20+6cmFAC-25, all three layers use modified asphalt as binder. After maintenance, there are few road rutting diseases.

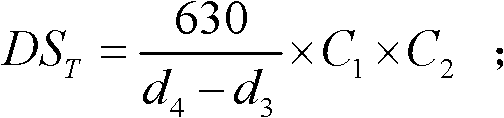

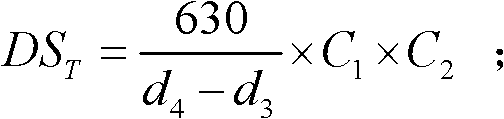

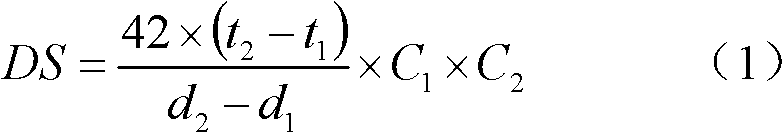

[0053] If the standard rutting test method is used to carry out rutting tests on the above six asphalt mixtures, the test conditions are standard test conditions: load 0.7Mpa, loading speed 42 times / min, uniform temperature field 60 °C. The test results are shown in Table 1.

[0054] Table 1 Standard rutting test results of asphalt mixture in each layer of surface course

[0055]

[0056] Compared with the relevant standards o...

Embodiment 2

[0063] A highway has a continuous uphill section of nearly 50 kilometers. The original pavement design surface structure is 4cmSMA-13+5cm modified asphalt AC-20+6cmAC-20. Due to the flaws in the code, the original design has not been tested for the anti-rutting performance of the structure, so it cannot be guaranteed that the structure is the most economical in terms of anti-rutting performance. In addition, the elevation difference of this road section is very large (the elevation of the foot of the slope is 920m, and the elevation of the top of the slope is 2350m); The foot temperature difference is about 9°C; continuous climbing will also cause the vehicle to travel slower and slower, especially for heavy-duty vehicles.

[0064] It can be seen that it is difficult to adopt uniform rutting test conditions for this ultra-long continuous uphill road section, and it needs to be processed in sections. It is divided into three sections, and the corresponding elevation ranges are...

Embodiment 3

[0071] The original design of the asphalt pavement structure of an expressway is 4cmSBS modified asphalt AC-13+6cmSBS modified asphalt AC-20+7cm AC-25. Due to the defects of the specification, the original design has not passed the structural anti-rutting performance test, so it cannot Ensure that the structure is the most economical from the point of view of anti-rutting performance. In addition, the traffic volume in the uplink direction and the downlink direction of the road is quite different. Here, the method of the present invention will be used for structural optimization to determine the respective optimal structural combinations for the uplink and downlink directions.

[0072] Representative rutting test conditions: Since the proportion of heavy-duty vehicles in the upward direction is larger than that in the downward direction, the corresponding rutting test loads are 1.1MPa and 0.9MP respectively: the temperature conditions of the road surface in the upward and downw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com