Anti-deforming structure of cam plate

A technology of deformation structure and cam disc, which is applied in the field of mechanical parts, can solve the problem of large operating force of the controller, and achieve the effect of preventing warping and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The specific embodiment of the present invention is described in detail below in conjunction with accompanying drawing:

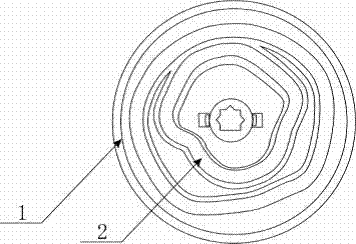

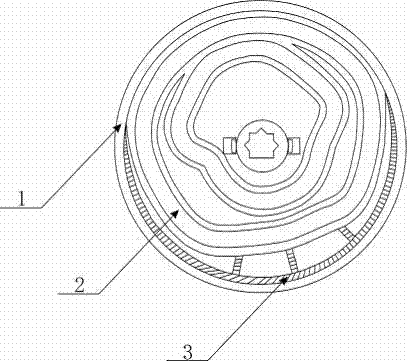

[0013] As shown in the figure, the anti-deformation structure of the cam disc includes a track groove 2 and a cam disc body 1; the cam disc body 1 and the track groove 2 are arranged as a whole; it is characterized in that: 1 The joint is also provided with reinforcing ribs 3.

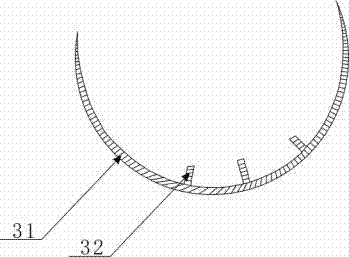

[0014] The reinforcing rib 3 is arranged on the outermost side of the connection between the cam plate body 1 and the track groove 2 . A rib body 31 and ribs 32 connected with the rib body 31 are arranged on the reinforcing rib 3, and there are at least three ribs 32. The ribs are provided to prevent warping of the cam disc body.

[0015] To sum up, using the anti-deformation structure of the cam provided by the utility model can effectively prevent the warping deformation of the cam disc body, and improve the movement mechanism that cannot run according to the set track dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com