Power control system and control method for engineering machinery

A technology of power control system and construction machinery, applied in fluid pressure actuating system components, mechanical equipment, fluid pressure actuating devices, etc., can solve the problem of affecting the response speed of the system, the operating cost is not effectively controlled, and the engine speed is slow to increase, etc. problems, to achieve the best economic results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

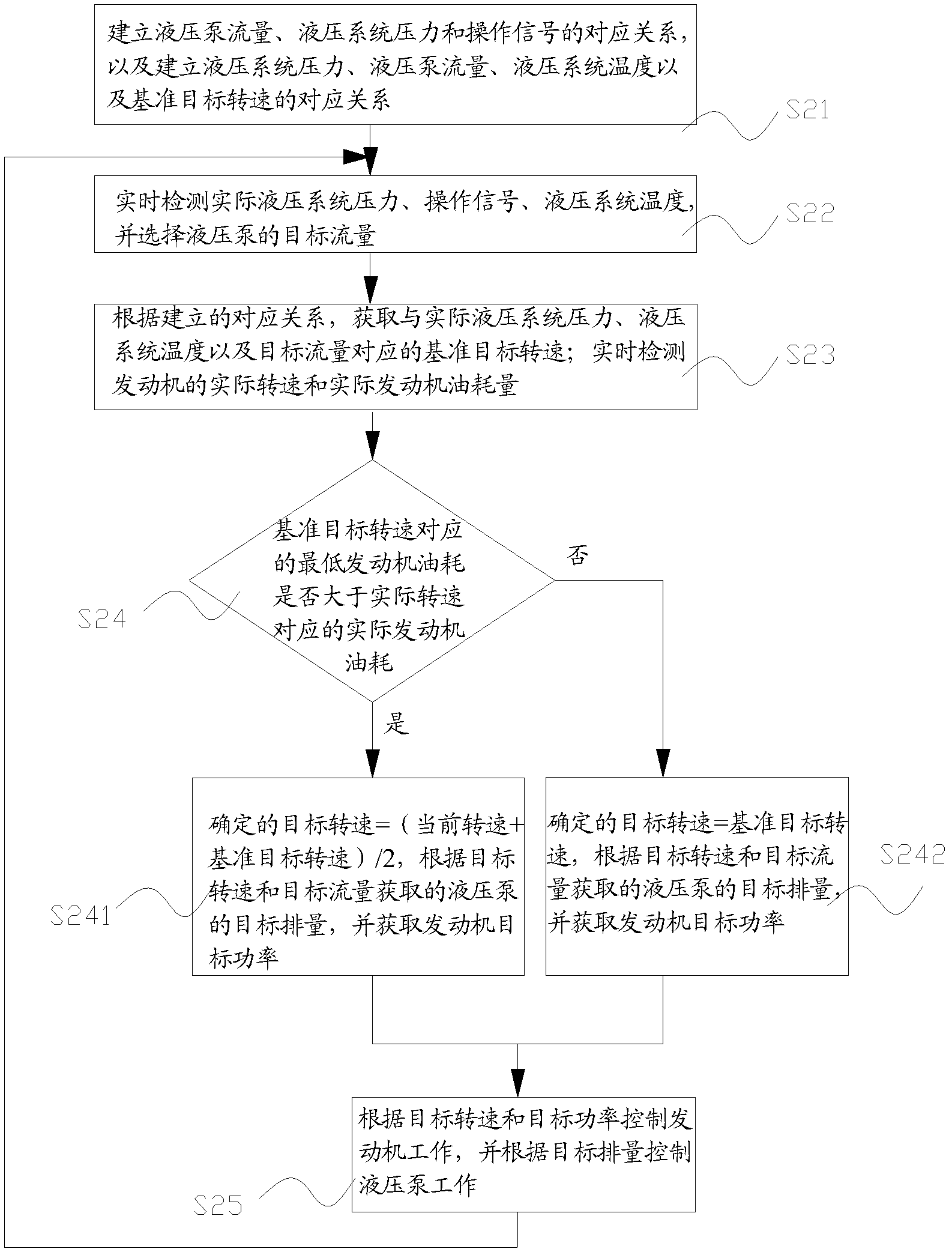

[0090] This embodiment comprises the following steps:

[0091] S21) Establishing the corresponding relationship between hydraulic pump flow, hydraulic system pressure and operation signal, and establishing the corresponding relationship between hydraulic system pressure, hydraulic pump flow, hydraulic system temperature and reference target speed;

[0092] In this specific implementation manner, further improvements are made to the first embodiment. Since the temperature of the hydraulic system has an impact on the efficiency of the hydraulic pump, when calculating the benchmark target speed according to the functional relationship between the engine speed and the system energy consumption, the influence of temperature on the system energy consumption can also be considered, that is, the system energy consumption η(n, v, T) =b(n, T) / ηb(p, n, v, t'), where t' is the temperature of the hydraulic system.

[0093] When the pressure of the hydraulic system, the flow rate of the hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com