Ballasting method in large-span girder cantilever construction

A mid-construction, long-span technology, applied to bridges, bridge construction, erection/assembly of bridges, etc., to achieve the effect of saving materials and not occupying the operating space of steel beams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

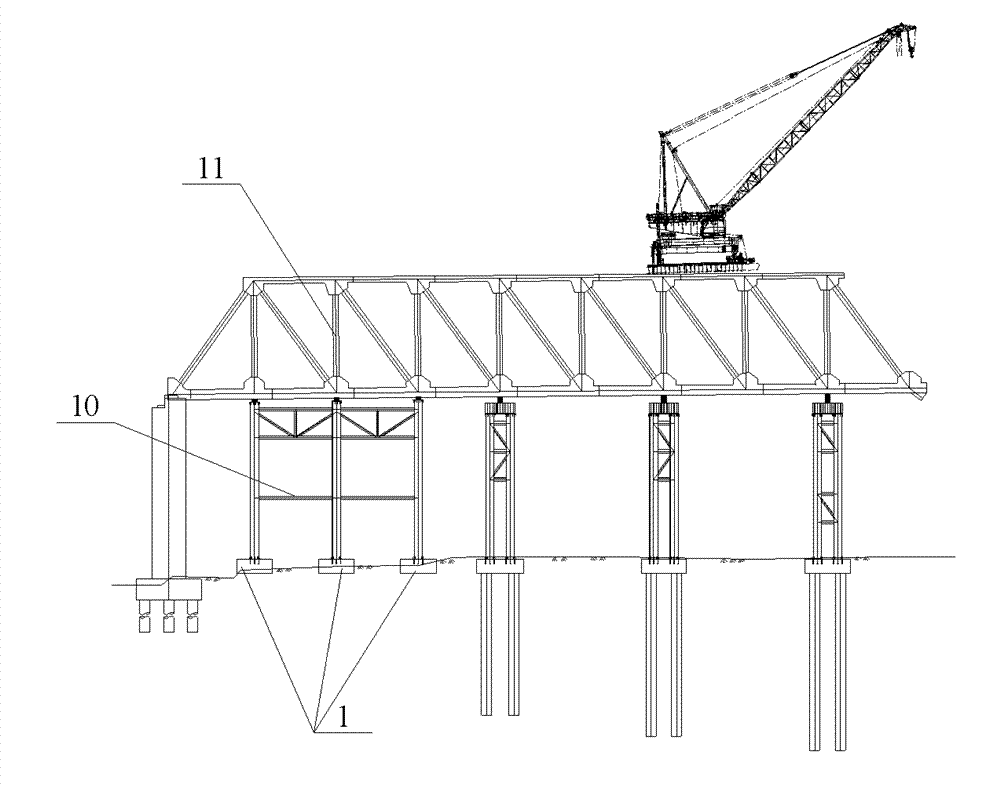

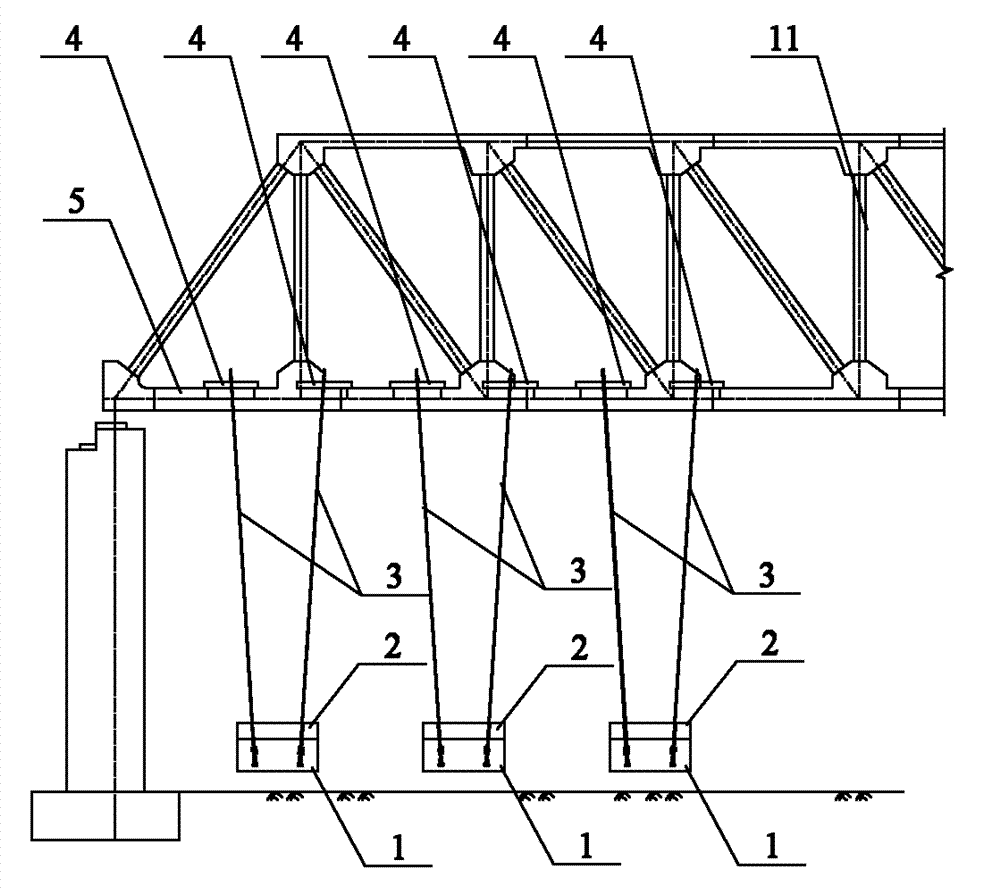

[0022] The invention provides a ballast method in the cantilever construction of a large-span steel beam, using the enlarged concrete foundation of the temporary pier of the side-span steel beam as the ballast material, that is, after the construction of the side-span steel beam is completed, the temporary pier is removed, The expanded concrete foundation of the side-span steel girder temporary buttress is connected to the steel girder bridge deck with steel strands, and the concrete enlarged foundation of the side-span steel girder temporary buttress is lifted through the steel strands to form a cross-span steel girder Heavy.

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0024] The ballast method in the large-span steel girder cantilever construction provided by the invention, concrete steps are as follows:

[0025] A10, such as figure 1 As shown, first construct the expanded foundation 1 of the side-span s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com