Interface-enhanced carbon fiber/polycaprolactam composite material and preparation method thereof

A technology of polycaprolactam and caprolactam, which is applied in fiber processing, textiles and papermaking, etc., can solve the problems of low grafting rate on the fiber surface, decline in the performance of carbon fiber body, and affect the overall performance of composite materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

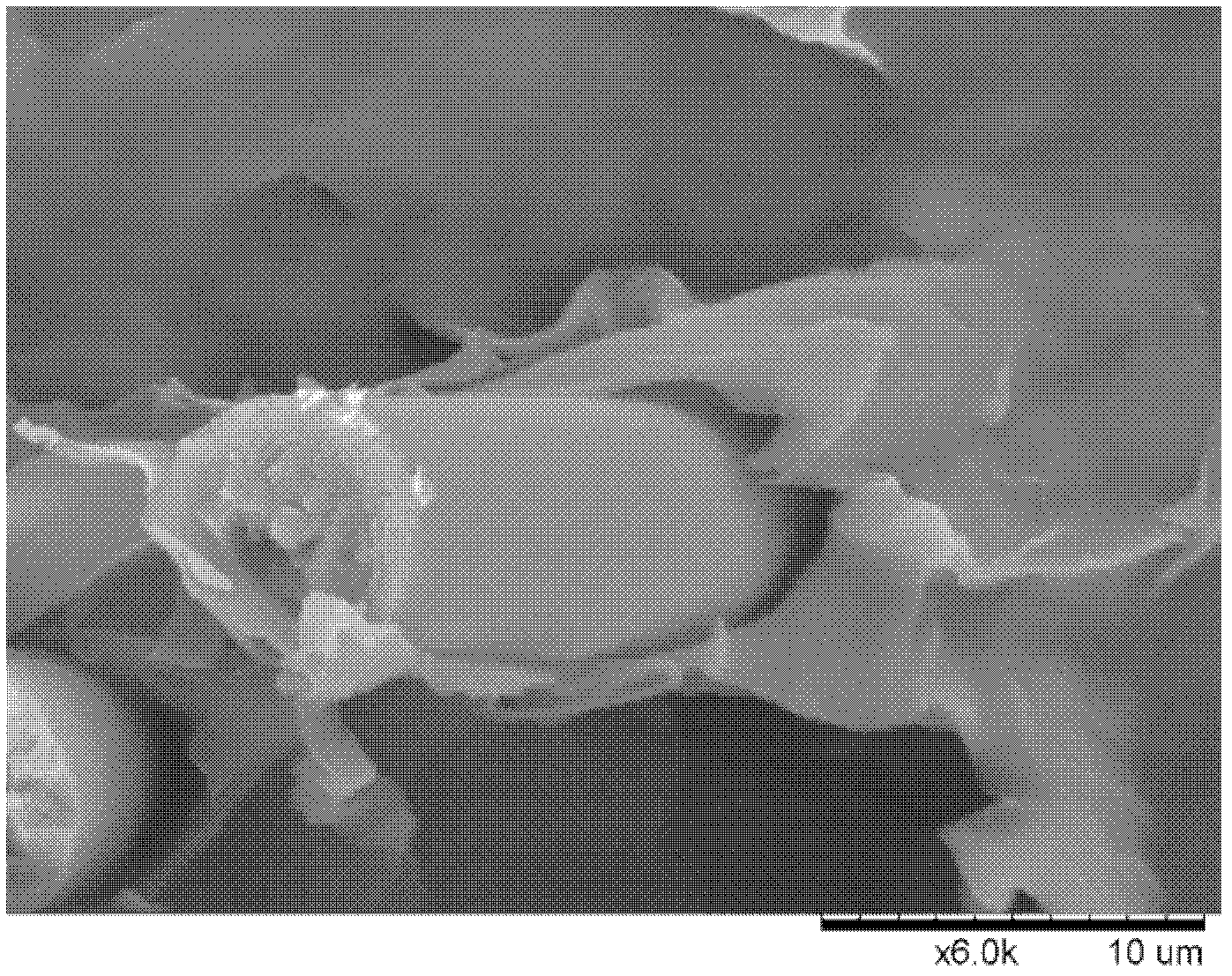

Image

Examples

preparation example Construction

[0094] Now further illustrate the preparation method of the carbon fiber / polycaprolactam composite material of the present invention in conjunction with specific embodiments of the present invention, comprising steps:

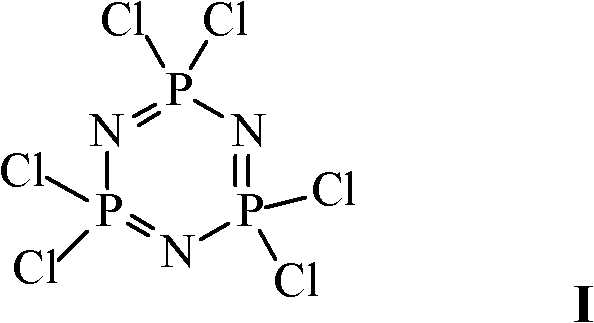

[0095] (i) In an inert solvent, in the presence of an acid-binding agent, the carbon fiber is reacted with hexachlorocyclotriphosphazene to form a carbon fiber whose surface is modified with hexachlorocyclotriphosphazene.

[0096] Preferably, the carbon fibers described in step (i) are carbon fibers that have undergone surface oxidation treatment in advance.

[0097] (ii) reacting the carbon fiber whose surface is modified with hexachlorocyclotriphosphazene obtained in step (i) with a caprolactam monomer to form a carbon fiber whose surface is grafted with a caprolactam monomer.

[0098] (iii) reacting the carbon fiber grafted with caprolactam monomer on the surface obtained in step (ii) with the caprolactam monomer, an initiator and an activator, thereby formi...

Embodiment 1

[0131] The preparation of embodiment 1 composite material 1

[0132] Step (1) Oxidation treatment of carbon fiber precursors (unsized): put 1 part by weight of carbon fiber into 100 parts by weight of 98% sulfuric acid, then reflux for 2 hours at a temperature of 100 ° C, then filter and wash with deionized water until The washing solution is neutral, and the surface oxidized carbon fibers are obtained by drying at a temperature of 60°C;

[0133] Step (2) Preparation of carbon fibers with caprolactam on the surface: put triethylamine and carbon oxide fibers into dry tetrahydrofuran according to a weight ratio of 10:100, then dissolve 5 parts by weight of hexachlorocyclotriphosphazene in tetrahydrofuran and slowly add In the above reaction solution, reflux reaction at 60°C for 12 hours, then add 8 parts by weight of caprolactam, and then reflux reaction at 60°C for 24 hours, then wash with tetrahydrofuran and deionized water for 4 to 5 times respectively Remove unreacted hexac...

Embodiment 2

[0136] The preparation of embodiment 2 composite material 2

[0137] Step (1) carbon fiber precursor (unsized) oxidation treatment: put 5 parts by weight of carbon fiber into 20 parts by weight of 60% nitric acid and 80 parts by weight of 98% sulfuric acid, and then reflux at a temperature of 100 ° C for 4 hours, and then Filter and wash with deionized water until the washing liquid is neutral, and dry at a temperature of 100°C to obtain surface oxidized carbon fibers;

[0138] Step (2) Preparation of carbon fibers with caprolactam on the surface: put triethylamine and carbon oxide fibers into dry tetrahydrofuran according to a weight ratio of 30:100, then dissolve 15 parts by weight of hexachlorocyclotriphosphazene in tetrahydrofuran and slowly add In the above reaction solution, reflux reaction at 65°C for 24 hours, then add 20 parts by weight of caprolactam, and then reflux reaction at 65°C for 18 hours, then wash with tetrahydrofuran and deionized water for 4 to 5 times re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com