Solvent-free polyurethane wear-resistant terrace paint and preparation method thereof

A solvent-free polyurethane and floor coating technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve problems such as harm to construction personnel and users, construction difficulties, etc., achieve good fluidity, ensure low-temperature drying speed, improve The effect of low temperature reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

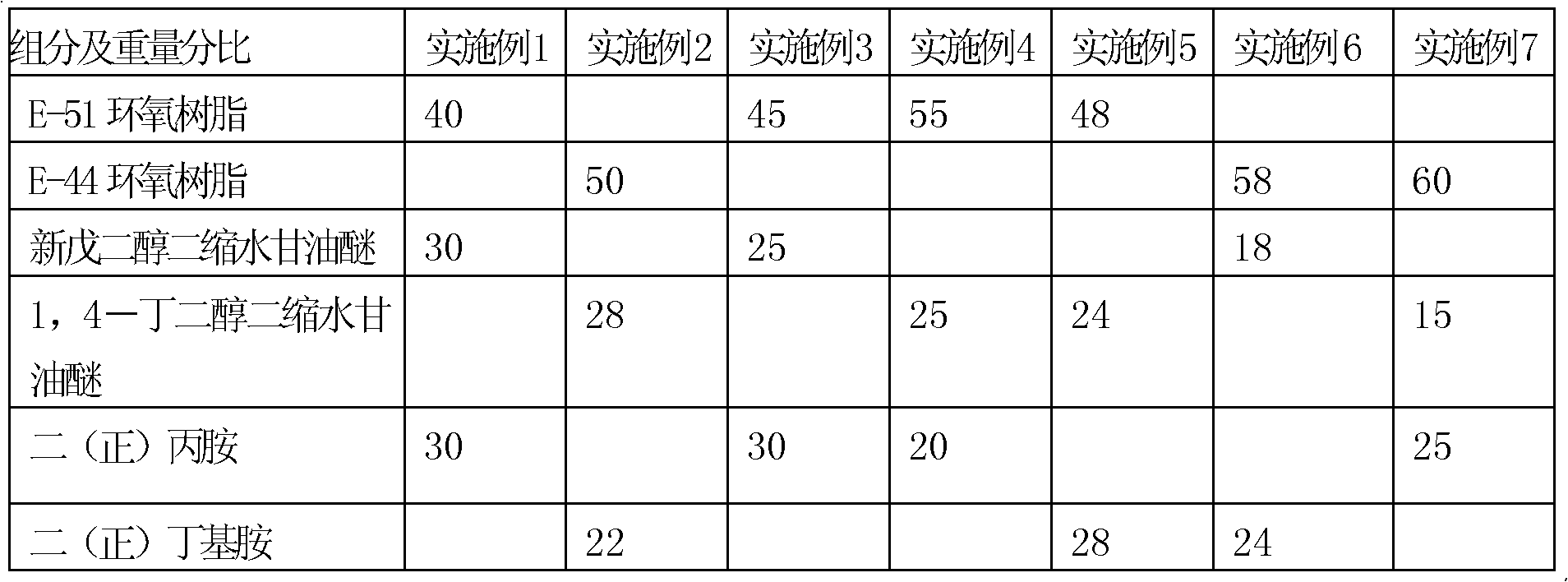

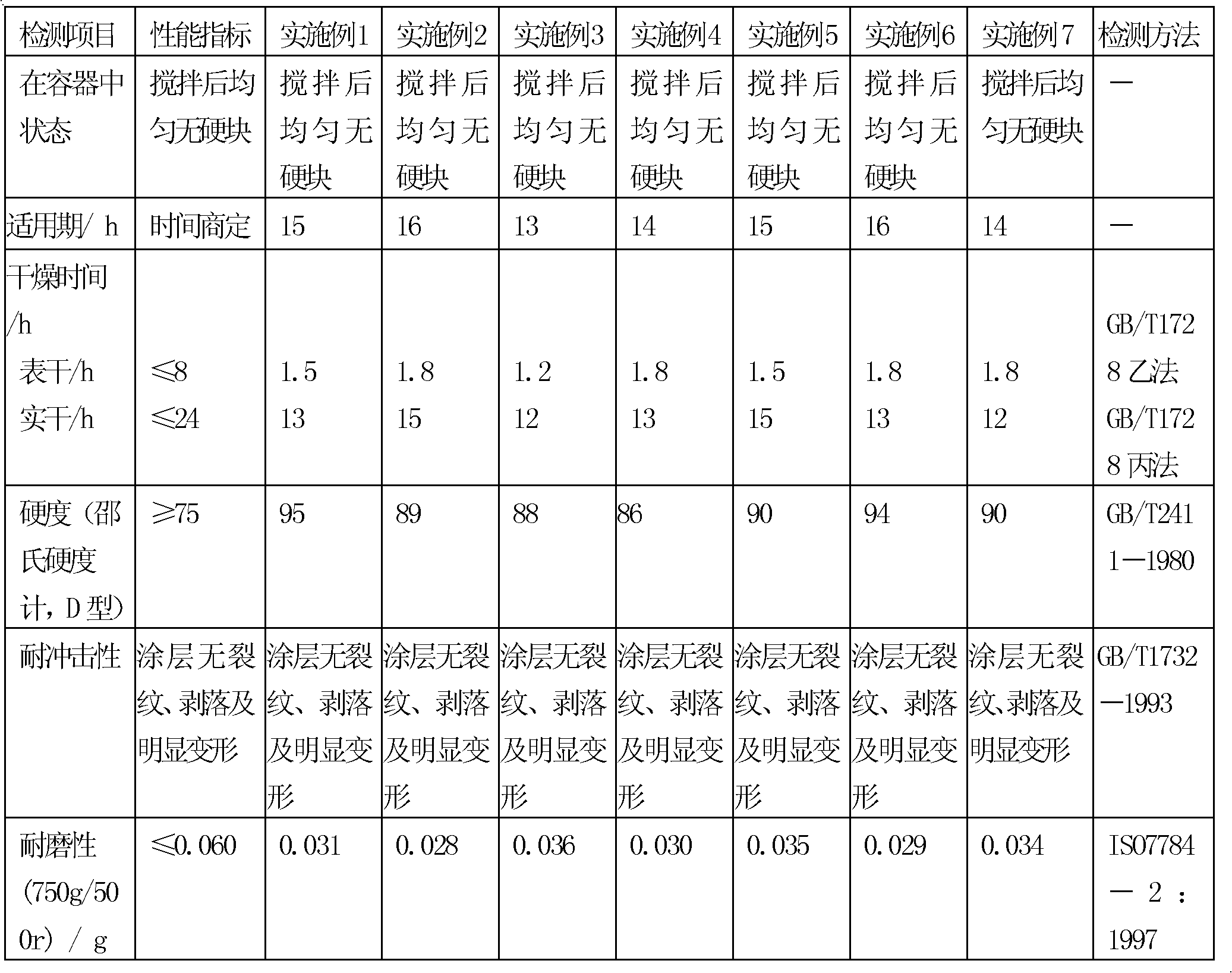

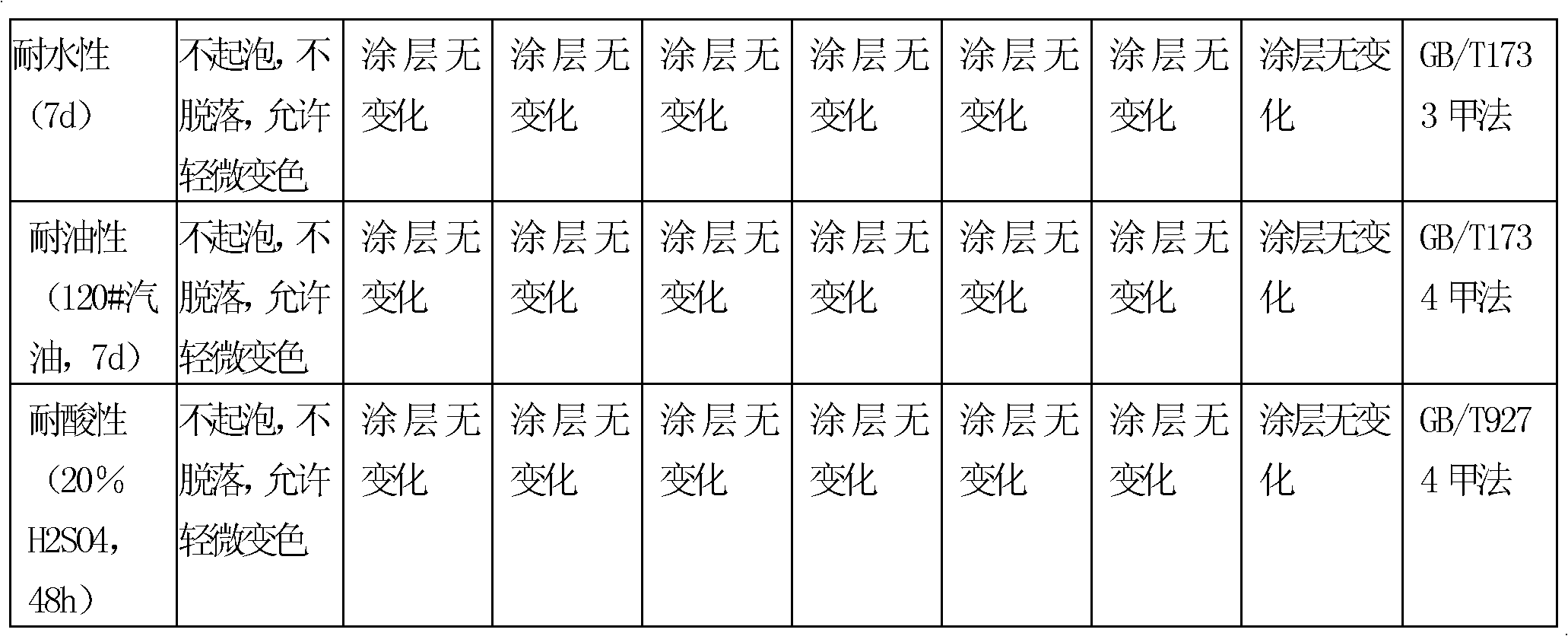

[0025] The solvent-free polyurethane wear-resistant floor coating of the present invention is composed of component A and component B. The component A and its mass fraction are: 60-80 parts of solvent-free hydroxyl-terminated epoxy resin and 1-13 parts of coloring Pigment, 15-22 parts of wear-resistant filler, 0.2-0.5 parts of defoamer, 0-0.3 parts of drier and 3-5 parts of oxazolidine water scavenger. The B component and the solvent-free isocyanate-terminated prepolymer with a mass fraction of 100 parts, the above-mentioned coloring pigments, wear-resistant fillers, defoamers, driers and oxazolidine water scavengers are available on the market.

[0026] The components and mass fraction of the solvent-free hydroxyl-terminated epoxy resin of the present invention are: 40-60 parts of low-molecular-weight liquid epoxy resin, 15-30 parts of diglycidyl ether and 20-30 parts of monobasic secondary amine. The solvent-free hydroxyl terminated epoxy resin has a viscosity of 300-500mPa·s / 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com