Special twistless roving impregnating compound for grinding wheel mesh

A technology of untwisted roving and sizing agent, applied in the field of medium alkali glass fiber sizing agent, can solve the problems of low production efficiency, high yarn production cost, poor bonding of phenolic resin glue, etc., to achieve high strength and meet high strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

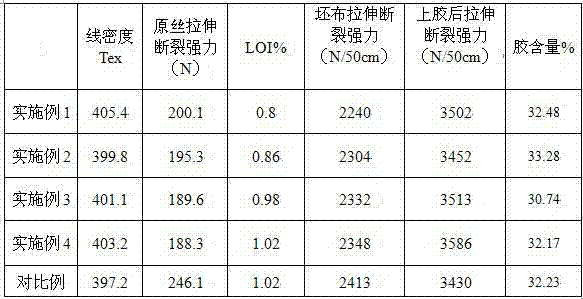

Examples

Embodiment 1

[0017] The solid content of the wetting agent is 8%, and the pH regulator: 0.4%. The ratio of the components of the wetting agent and the solid content to the solid content of the overall wetting agent is as follows: coupling agent A (A-100): 5%, coupling agent B (A-187): 10%, polyurethane (Baybond 3497): 15%, epoxy emulsion (Neoxil 965): 25%, polyester (Neoxil 954 / D): 30%, lubricant (PEG6000): 15% .

Embodiment 2

[0019] The solid content of the wetting agent is 8%, the inorganic acid pH regulator: 0.4%, and the ratio of the components and solid content of the wetting agent to the solid content of the overall wetting agent is as follows: coupling agent A (A-100): 5%, coupling agent A (A-100): 5%, Joint agent B (A-187): 10%, polyurethane (Bayer's Baybond 403): 30%, epoxy emulsion (DSM's Neoxil 965): 15%, polyester: (DSM's Neoxil 9630) 30%, Lubricant Stearic Acid: 10%.

Embodiment 3

[0021] The solid content of the sizing agent is 10%, the pH regulator (organic acid): 0.4%, and the ratio of the components and solid content of the sizing agent to the solid content of the overall sizing agent is as follows: Coupling agent A (A-100): 5% , coupling agent B (A-187): 10%, polyurethane (Baybond 403 from Bayer): 15%, epoxy emulsion (Neoxil 9600 from DSM): 30%, polyester Neoxil 966 / M from DSM) : 20%, lubricant (polyethyleneimine polyamide salt): 20%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com