Fully edge turning method for tissues of blank boxes and fully edge turning mechanism adopting fully edge turning method

A technology of blank boxes and face paper, which is applied in the field of carton forming methods and forming machines, which can solve the problems of uneven blank boxes, uneven heights, and affecting the overall aesthetics of cartons, so as to improve the overall aesthetics and width to the side. smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

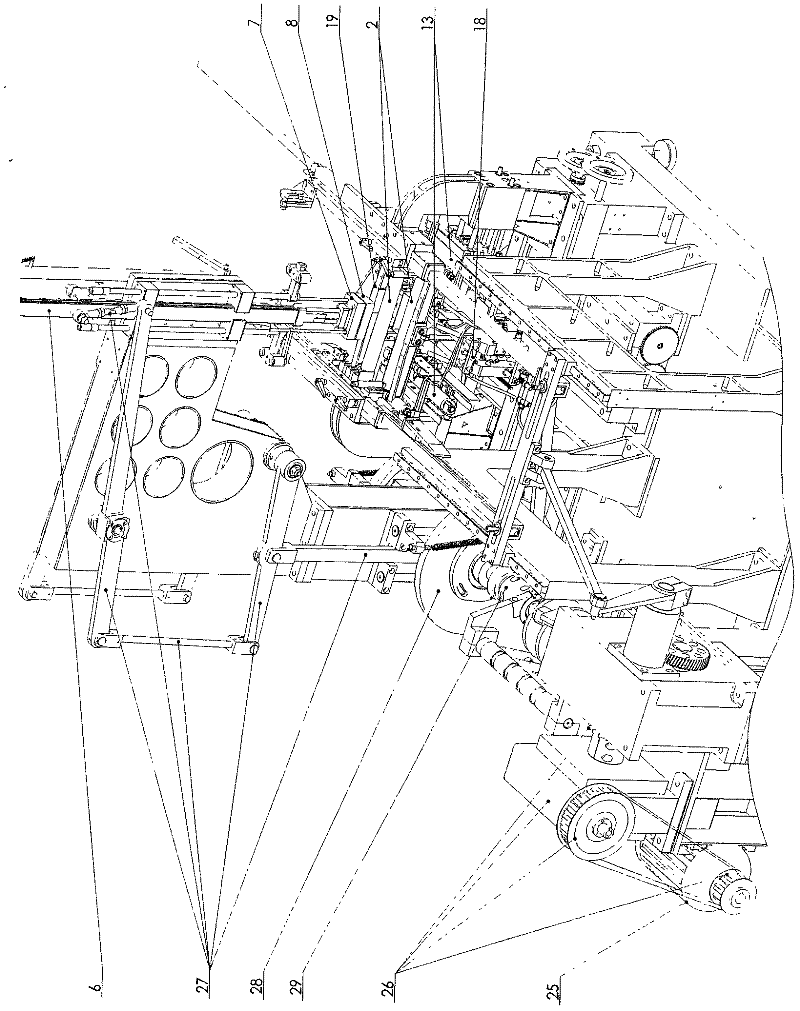

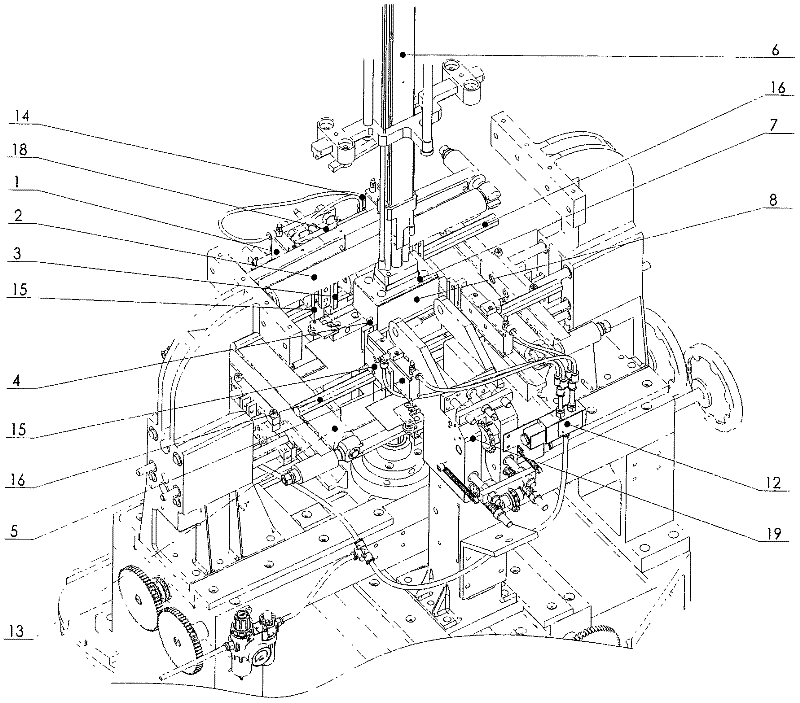

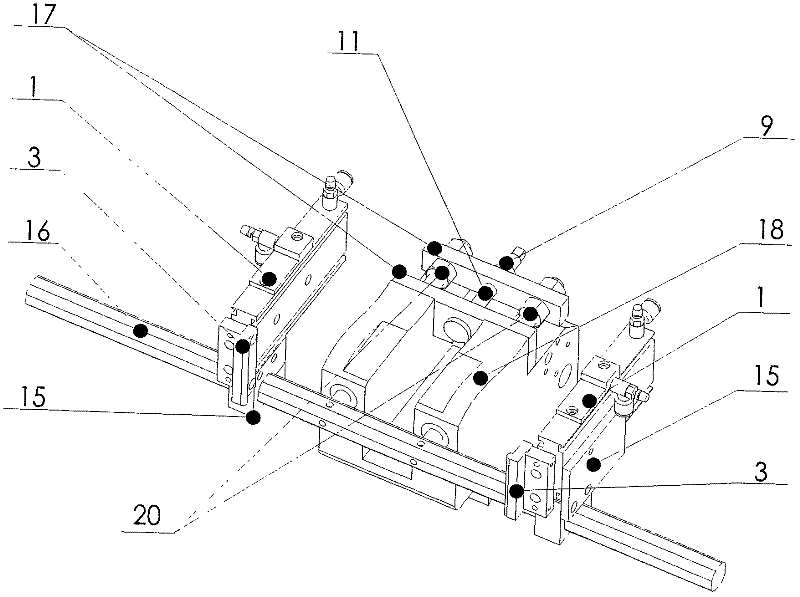

[0012] refer to figure 1 , figure 2 It can be seen that the method for fully folding the blank box face paper applied to the carton forming machine in the present invention is as follows: first, the blank box face paper 8 (through the mold 7 and the slide bar 6) after the positioning and bonding process is conveyed from top to bottom, When transported to the blank box long side bonding station, the long side part of the face paper is brushed and bonded on the blank box long side by the box long rubber roller 2; When the ear station is at the ear station, the front and rear ear knives are controlled by the telescopic action of the front and rear ear folding cylinders in turn, and the ear folding part of the facial tissue is firstly folded to the full width of the front box, and then to the full width of the rear box for the second time. Fold the ears, and the second full ear folding (the ear folding part of the tissue paper) will cover all the first full ear folding (the ear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com