Processing method of 3D flower-type fleece fabric

A plush fabric and processing method technology, applied in the field of fabric processing, can solve problems such as high production cost, high wool height, and insufficient pattern, achieve beautiful appearance, overcome single structural design, and improve overall aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] 1. Introduction to the structure of 3D flower roller:

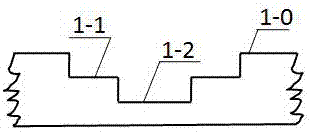

[0028] Depend on figure 1 It can be seen that the traditional burnt-out pattern roller, 1-0 is the outer layer of the pattern roller, 1-1 is the first pattern layer of the pattern roller, and 1-2 is the second pattern layer of the pattern roller. The burnt-out effect of the fabric has great limitations, the number of layers of pattern is not enough and the pattern is not delicate enough.

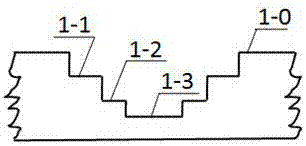

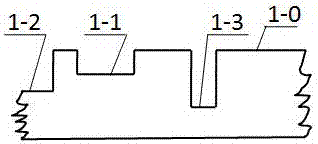

[0029] 3D flower roll structure such as figure 2 , image 3 As shown, 1-0 is the outer layer of the pattern roller, 1-1 is the first pattern layer of the pattern roller, 1-2 is the second pattern layer of the pattern roller, and 1-3 is the third pattern layer of the pattern roller. Layer pattern layer.

[0030] Second, the fabric weaving:

[0031] Fabrics are knitted on a gauge E28 or E32 high-speed tricot machine.

[0032] 3. Burn-out process:

[0033] 1. Pre-order type:

[0034] The presetting temperature is controlled...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com