Cationic polymer thickeners

A technology of cationic polymers and thickeners, applied in detergent compositions, detergent compounding agents, organic detergent compositions, etc., can solve unsatisfactory problems and achieve good anti-aging stability and good growth viscous effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A) Synthesis of Cationic Polymers This example describes the preparation of suitable cationic polymers.

[0039] The aqueous phase of the water soluble polymer is prepared by mixing together the following components:

[0040] — 47.0 parts of dimethylaminoethyl methacrylate chloride quaternary ammonium salt,

[0041] - 6.0 parts of acrylamide,

[0042] - 0.03 parts of pentasodium diethylenetriamine pentaacetate,

[0043] — 14 parts water,

[0044] — 0.03 parts of methylenebisacrylamide,

[0045] - 0.4 parts of sodium formate,

[0046] -Use citric acid to adjust the pH value to between 4.0-6.0.

[0047] The oil phase is prepared by mixing together the following components:

[0048] — 2.0 parts of sorbitan monooleate,

[0049] - 5.5 parts polymer stabilizer,

[0050] — 19.0 parts white mineral oil,

[0051] - 6.0 parts dearomatized hydrocarbon solvent,

[0052] The two phases are mixed together in a high-shear rate reactor at a ratio of 1 part of oil to 1 part ...

Embodiment 2-5

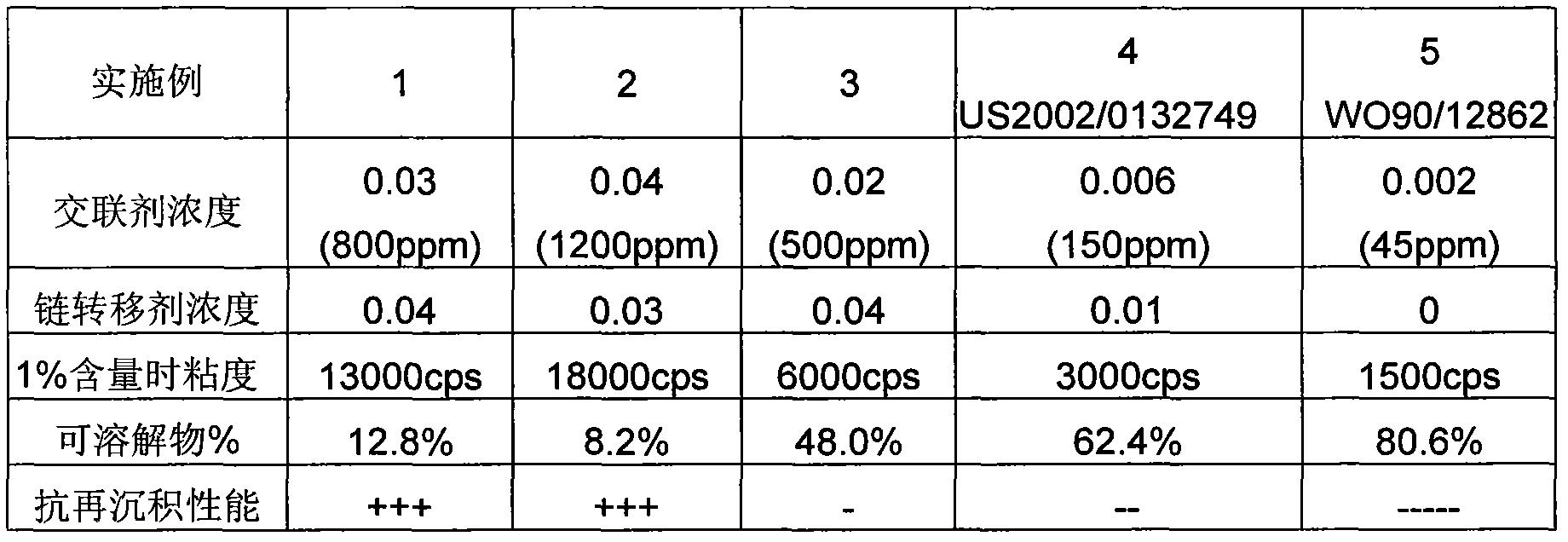

[0079] Change the amount of cross-linking agent and chain transfer agent, repeat the method of embodiment 1, all results are listed in table 1.

[0080]

[0081] Table 1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com