Steel pipe pile for rectangular pier cofferdam

A technology for steel pipe piles and bridge piers, which is applied to sheet pile walls, buildings, and foundation structure engineering, and can solve the problem that the bending modulus of steel sheet pile cofferdams cannot meet the cross-sectional resistance moment, and it is difficult for large tugboats and floating cranes to enter, and internal In order to achieve the effect of simple structure, enhanced rigidity, and simple and convenient support, the construction cannot be carried out due to the intensive support.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

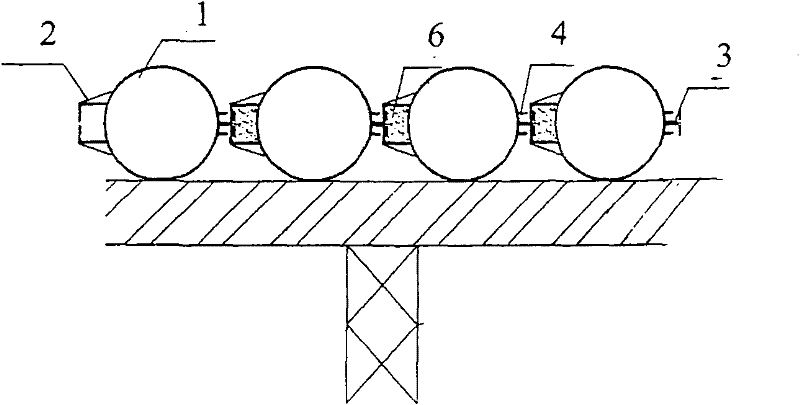

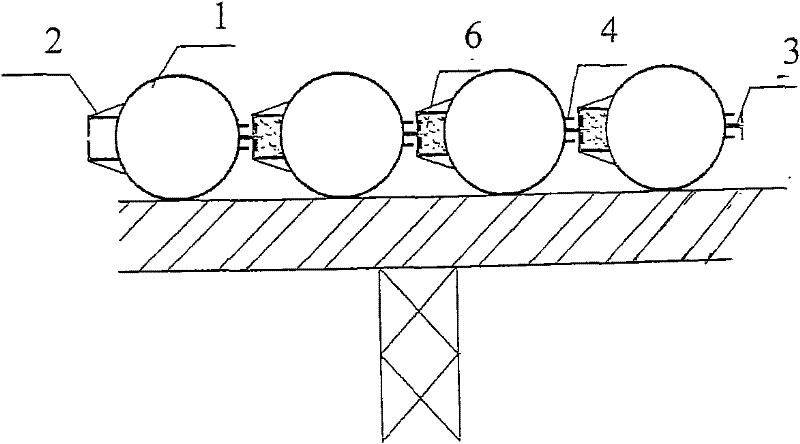

[0010] A steel pipe pile for a cofferdam of a rectangular pier, in which a female buckle 2 and a male buckle 3 are respectively processed on both sides of a spiral pipe 1. Above-mentioned male buckle and female buckle adopt unequal angle steel to make and male buckle and female buckle axis become 180 °, and corner pipe 5 becomes 90 °. In order to ensure the accuracy of positioning and the spatial position of the inner cavity of the female buckle during the insertion and driving of the steel pipe pile, a stopper 4 is added to the outer side of the male buckle. When carrying out lock grouting, the cloth bag 6 is lined at the lock mouth of the male buckle and the female buckle.

[0011] When using the present invention, the steel pipe piles are connected to each other from the beginning along the periphery of the cap to form an integral steel pipe pile, and they are lifted one by one, and then the steel pipe piles are lifted to the design position by mechanical assistance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com