Novel filament winding bobbin chuck

A technology of wire winding tube and pipe clamp, which is applied in the direction of conveying filamentous materials, thin material processing, transportation and packaging, etc., which can solve the problems of short service life of the chuck, affecting the quality of processing, and small frictional driving force, etc., to achieve The effect of smooth rotation, long service life, and large friction driving force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

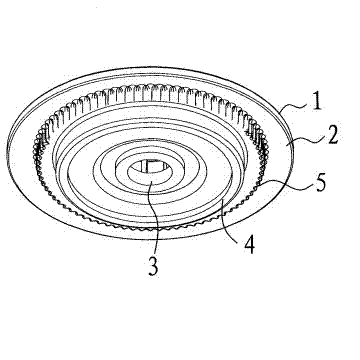

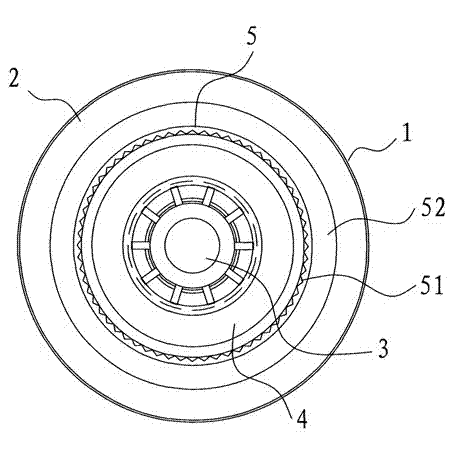

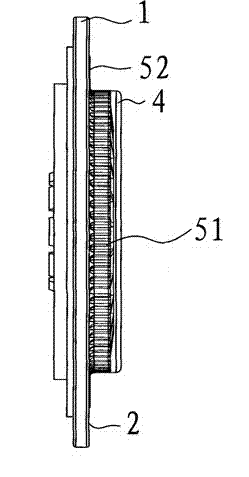

[0019] Such as figure 1 A new type of wire-wound bobbin chuck is shown, including a disc-shaped disc body 1 made of plastic, a central hole 3 located in the center of the disc body 1 for installing the drive shaft, and a connection between the disc body 1 and the bobbin 8. The contact end surface 2 where the end surfaces are in contact, and the columnar platform 4 axially extending on the contact end surface 2 for matching with the inner circle of the bobbin 6. In the present invention, the outer surface of the columnar platform 4 is coated with metal layer 5 , the metal layer 5 forms an uneven transmission portion 51 on the outer peripheral surface of the columnar platform 4 .

[0020] In order to achieve a better use effect, in this embodiment, the transmission part 51 is evenly arranged in a zigzag shape along the outer circumferential direction of the columnar platform 4, which can generate a larger friction coefficient; and the metal layer 5 and the disc body 1 are integr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com