Electrophotographic developer carrier core material, manufacturing method therefor, electrophotographic developer carrier, and electrophotographic developer

A carrier core material, electrophotographic technology, applied in the direction of developer, electrographic recording, instruments, etc., can solve problems such as consumption, and achieve the effect of preventing the reduction of image quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0120] As a raw material, ready to be crushed into an average particle size D 50 Fe of about 1.8 μm 2 o 3 , and was crushed into an average particle size D 50 MgO, Mn of about 1 μm 3 o 4 , P (red phosphorus manufactured by Phosphorus Chemical Co., Ltd.) powder. The raw materials are respectively Fe 2 o 3 : 71.2% by mass, Mn 3 o 4 : 23.7% by mass and MgO: 5.1% by mass were mixed. P powder according to relative to Fe 2 o 3 , MgO, Mn 3 o 4 The amount of mixed raw material powder was weighed in an amount of 0.25% by mass in conversion of P element.

[0121] On the other hand, Sannopco Co., Ltd. product "SN wet 980" added with 1.0% by mass of polycarboxylate ammonium dispersant as a dispersant and 0.05% by mass as a wetting agent in water as a dispersion medium, and 0.02% by mass as The liquid (medium liquid) of the polyvinyl alcohol of the binder.

[0122] Put P powder into the medium liquid, after fully dispersed, put in the above-mentioned weighing Fe 2 o 3 , Mg...

Embodiment 2

[0127] According to relative to Fe 2 o 3 , MgO, Mn 3 o 4 The carrier core material of Example 2 was obtained in the same manner as in Example 1 except that the amount of the mixed raw material powder was 0.5% by mass in terms of P element, and the P powder was added by weighing.

[0128] Table 1 shows the additive amount of the carrier core material, powder properties, magnetic properties, and evaluation test results described later.

[0129] further, figure 2 The SEM image (a) of 4000 times of the carrier core material in Example 2, the mapping image (b) of P measured by EDS at the same part and the same magnification as the above SEM image, and the mapping image (c) of Mg .

Embodiment 3

[0131] According to relative to Fe 2 o 3 , MgO, Mn 3 o 4 The carrier core material of Example 3 was obtained in the same manner as in Example 1, except that the amount of the mixed raw material powder was 1.0% by mass in terms of P element, and the P powder was added by weighing.

[0132] Table 1 shows the additive amount of the carrier core material, powder properties, magnetic properties, and evaluation test results described later.

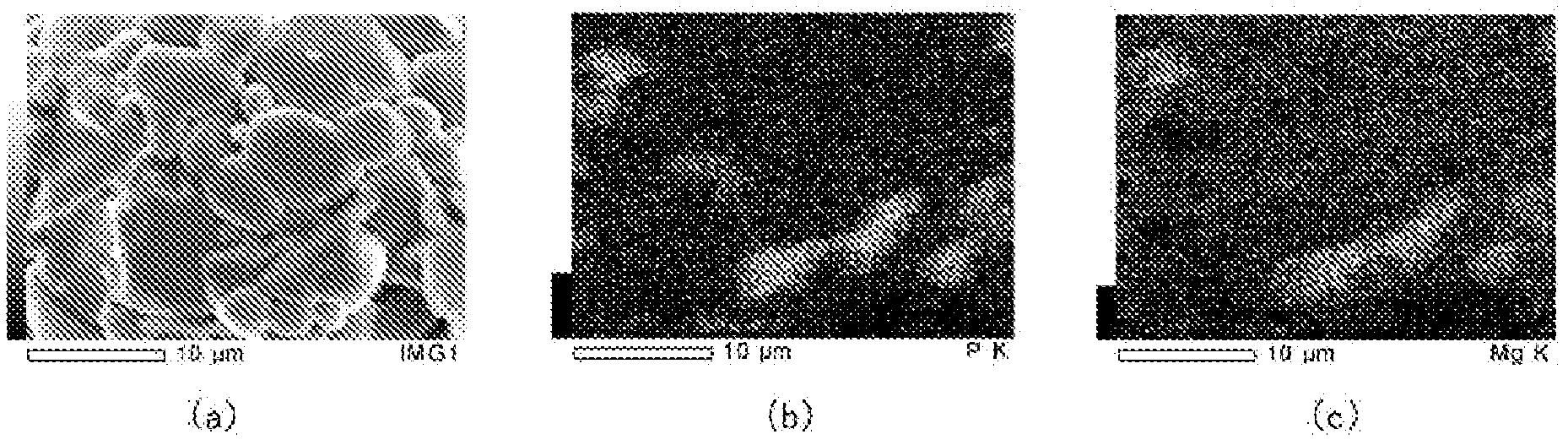

[0133] further, image 3 The SEM image (a) at 4000 magnification of the carrier core material of Example 3, the mapping image (b) of P and the mapping image (c) of Mg measured by EDS at the same part and at the same magnification as the above SEM image are shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com