Fuel injection valve for internal combustion engines

A technology of fuel injection valve and internal combustion engine, which is applied in the direction of fuel injection device, special fuel injection device, charging system, etc., can solve problems such as cost-effective manufacturing, and achieve the effect of stable flow decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

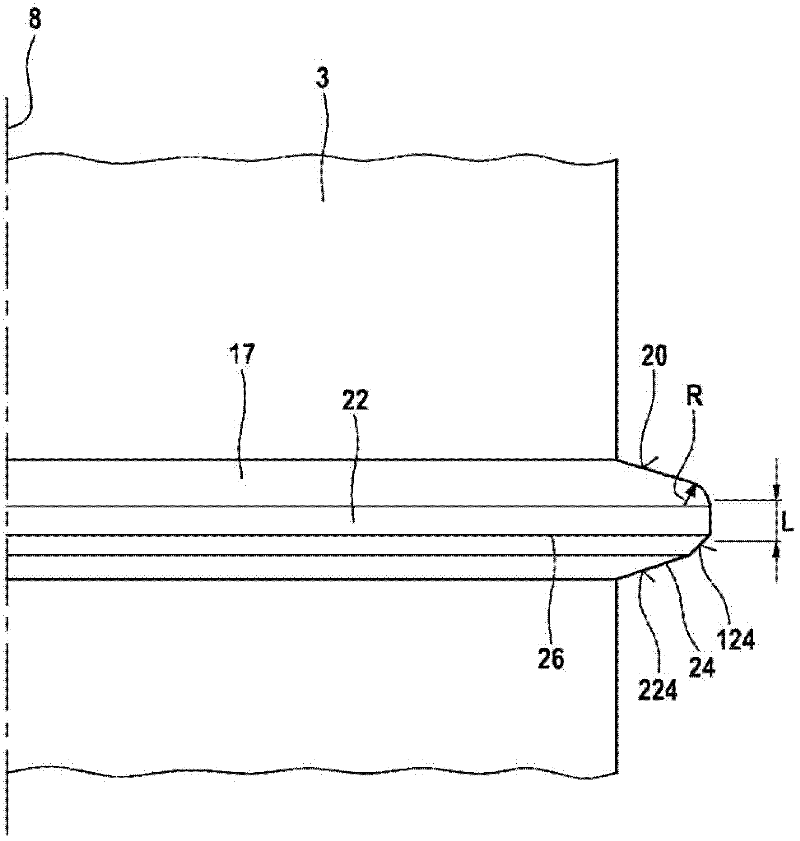

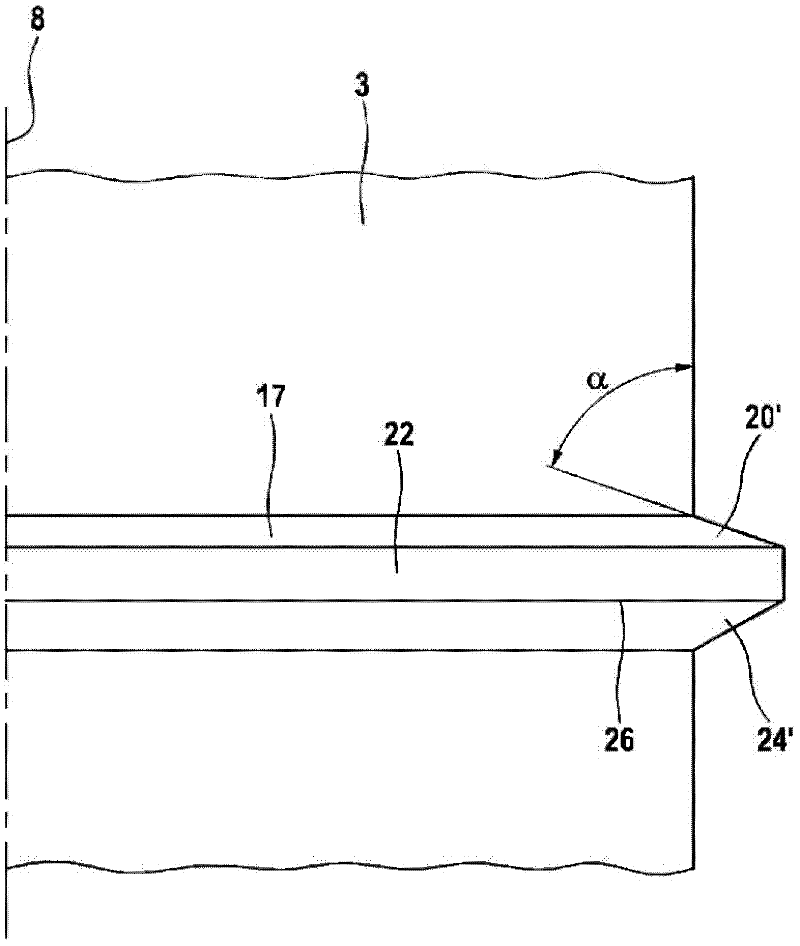

[0018] exist figure 1 The fuel injection valve according to the invention is shown in longitudinal section, wherein only the part of the injection valve which is facing the combustion chamber in the installed position of the internal combustion engine is shown. The fuel injector 1 has a valve body 2 in which a pressure chamber 5 is formed in the form of a bore. The pressure chamber 5 is delimited on the combustion chamber side by an essentially conical valve seat 9 from which a plurality of injection openings 7 emerge. Arranged in the pressure chamber 5 is a longitudinally displaceable valve needle 3 which is embodied rotationally symmetrically with respect to the longitudinal axis of the pressure chamber 5 . The valve needle 3 is guided in the guide section 103 in the pressure chamber 5 , wherein a fuel flow is ensured through milled portions 14 formed on the outside of the guide section 103 and past the guide section 103 . On its end facing the valve seat, the valve needle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com