Headbox for a machine for producing a fibrous web

A fiber material and headbox technology, applied in the paper machine, papermaking, paper machine wet end, etc., can solve the problems of time-consuming and labor-intensive reassembly of the headbox, unusable headbox, etc., and achieve less downtime and good volume Flow constant, technically reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

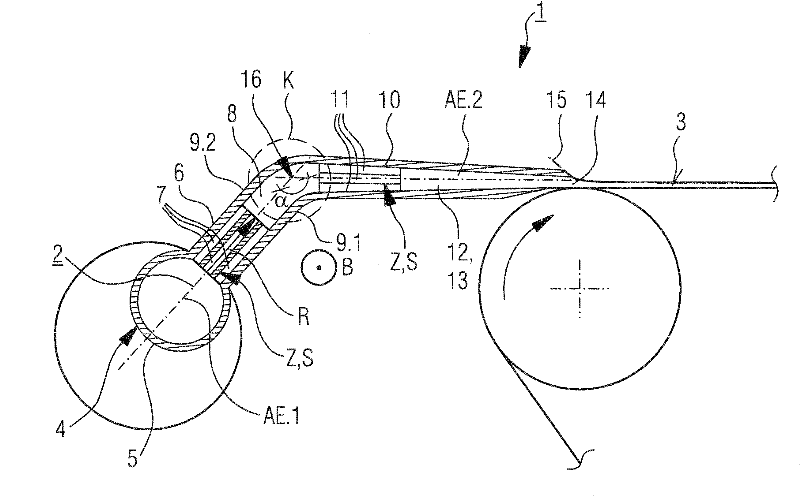

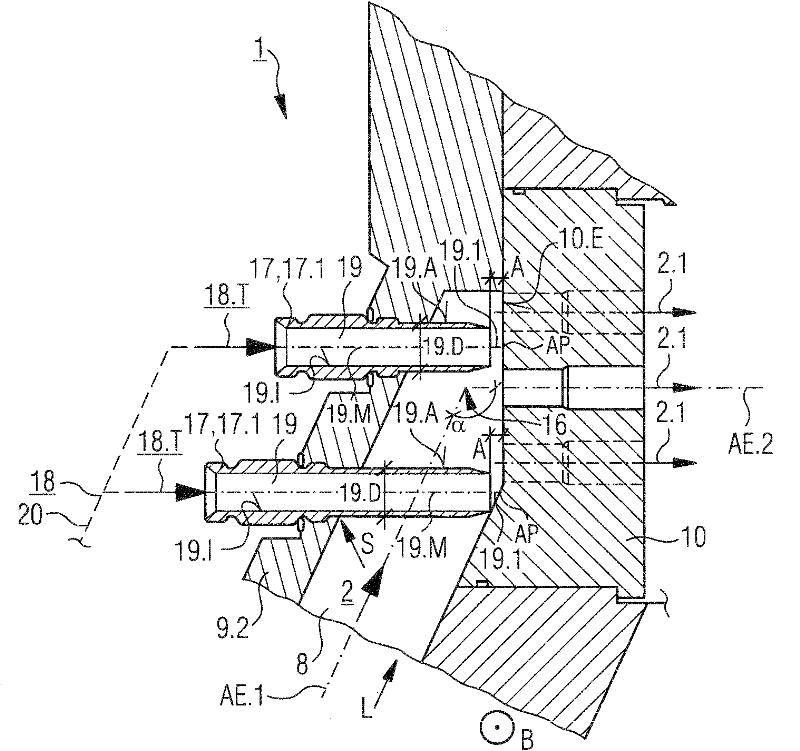

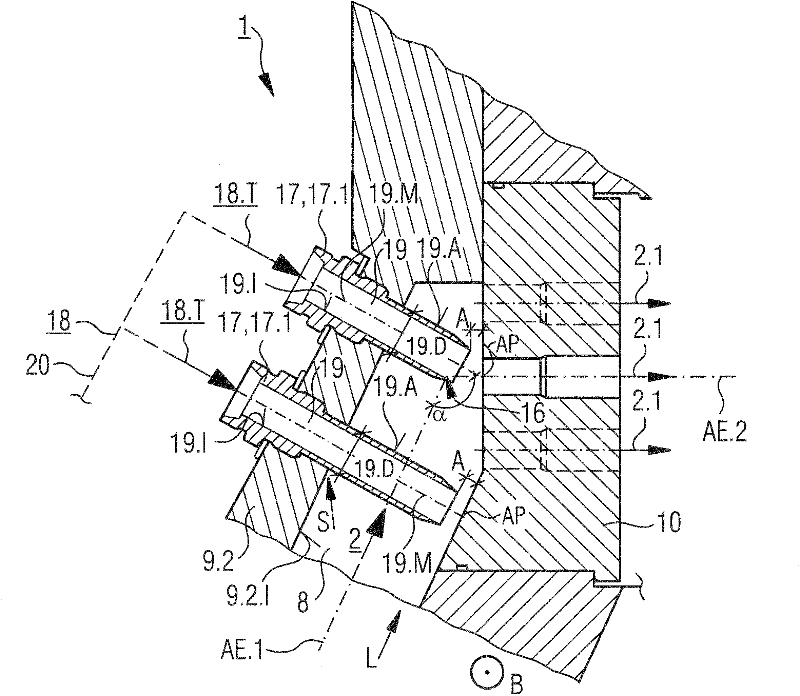

[0034] figure 1 A vertical and schematic longitudinal section through an exemplary embodiment of a headbox 1 for a machine for producing a fibrous material web 3 from a fibrous material suspension 2 is shown. It goes without saying that the illustrated headbox 1 can also be configured as a multilayer headbox for producing the fibrous material web 3 using at least two different fibrous material suspensions. The fibrous material web 3 may here in particular be a paper, cardboard or tissue paper web.

[0035] The headbox 1 has a conveying device 4 for conveying the fibrous material suspension 2 , for example embodied as a transverse distribution pipe 5 shown or a circular distributor with a plurality of hoses, not shown.

[0036] For example, the distribution tube orifice plate 6 of three rows is directly connected to the conveying device 4 along the flow direction R (arrow) of the fiber material suspension 2, and the distribution tube orifice plate 6 of the three rows has a lar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com