Device and method for catching and stretching weft threads in weaving machine

A weft yarn, device technology used in the field of catching and stretching weft yarns to achieve a firm and uniform fabric edge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

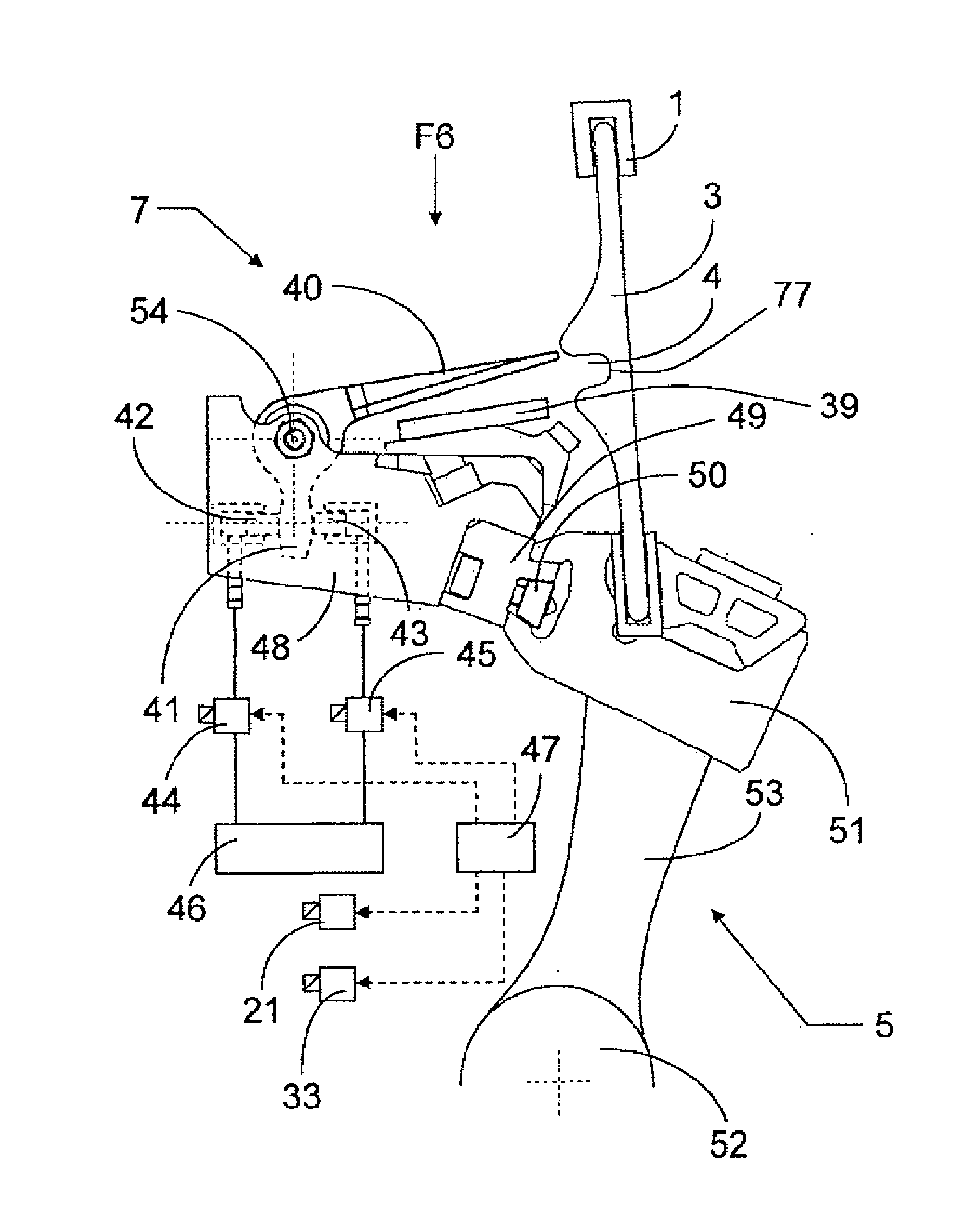

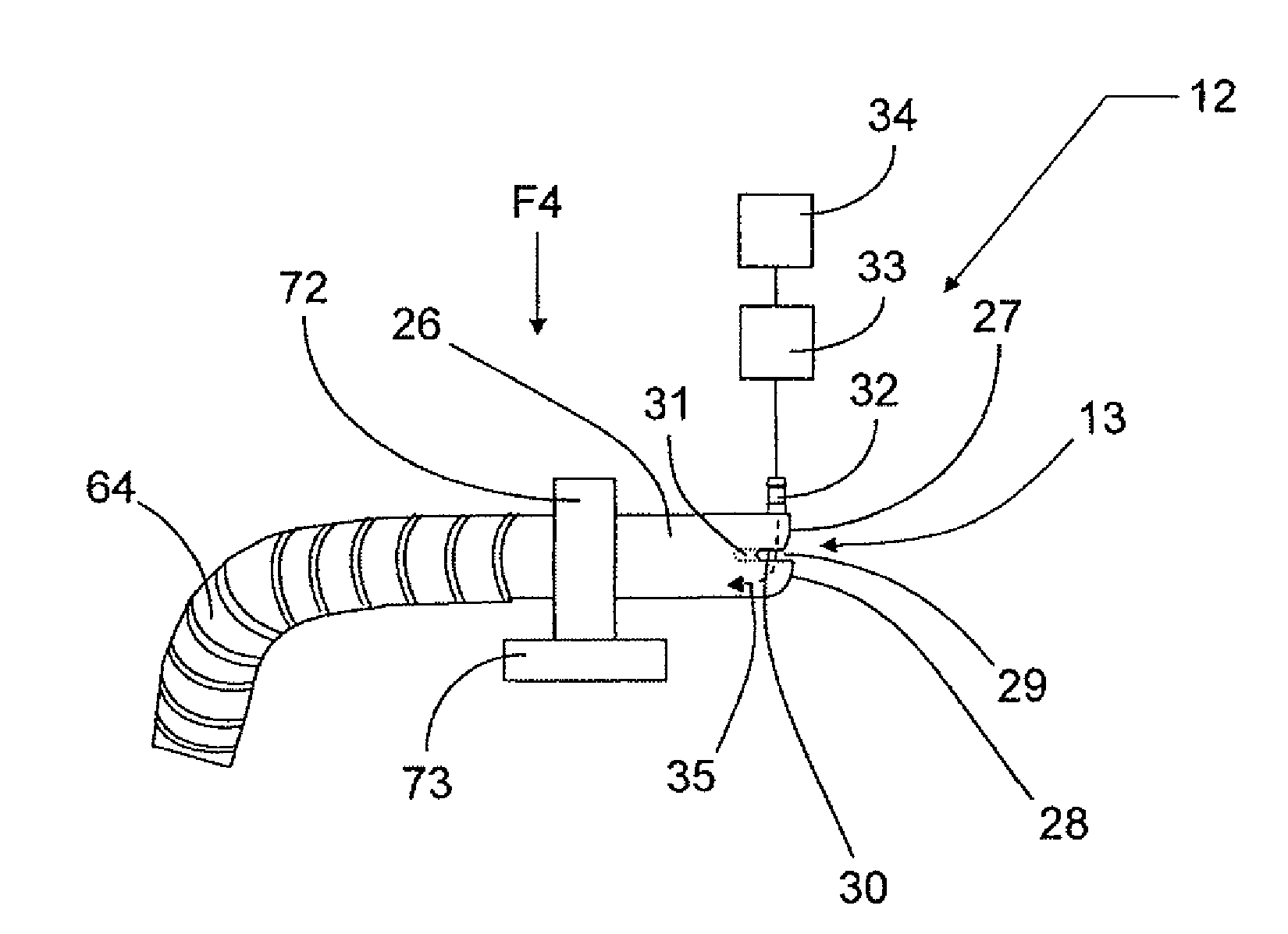

[0047] figure 1 with 2 A part of an air jet loom is shown, which comprises a reed 1 and a device 2 according to the invention. The reed 1 is assembled by a plurality of sheets 3 having a U-shaped profile, and the plurality of sheets 3 are attached next to each other and together form a U-shaped guide groove 4 for the weft. During weaving, the weft thread is brought into the shed by means of the air flow into the U-shaped guide groove 4, which air flow conveys the weft thread through the U-shaped guide groove 4 in the reed 1. This airflow is generated by a main blower (not shown) and by a number of auxiliary blowers (not shown) positioned along the guide groove 4. The steel reed 1 is fastened in a known manner to the braided sley 5 shown schematically. In this case, the reed 1 is continuously embodied and extended to pass the device 2 according to the invention.

[0048] The pneumatic suction nozzle 6 attached close to the reed 1, the yarn clamp 7 for the weft thread, and the gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com