Method for manufacturing phthalic acid/phthalic acid hydride

A technology for phthalic anhydride and phthalic acid, which is applied in the field of technology and equipment for preparing phthalic acid/phthalic anhydride, can solve problems such as strong corrosion and expensive construction materials, and achieve high conversion rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

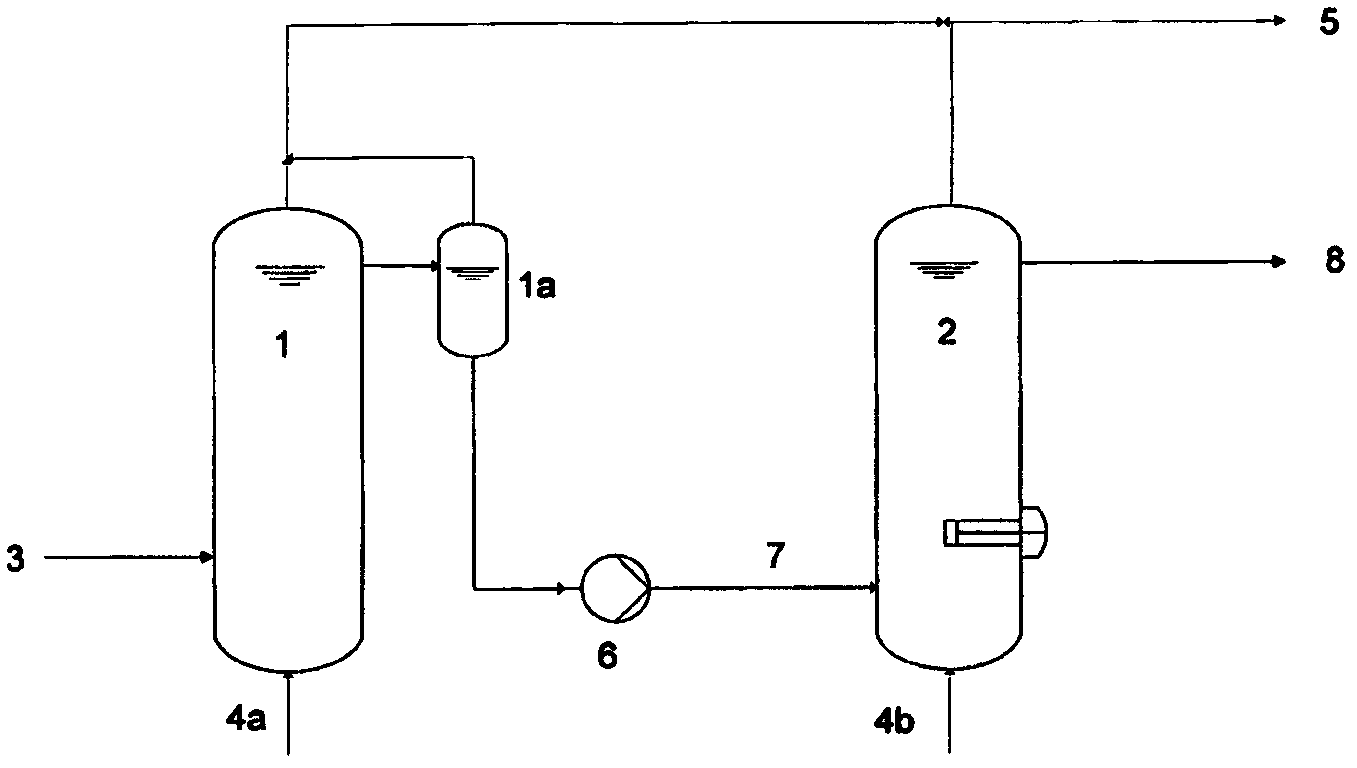

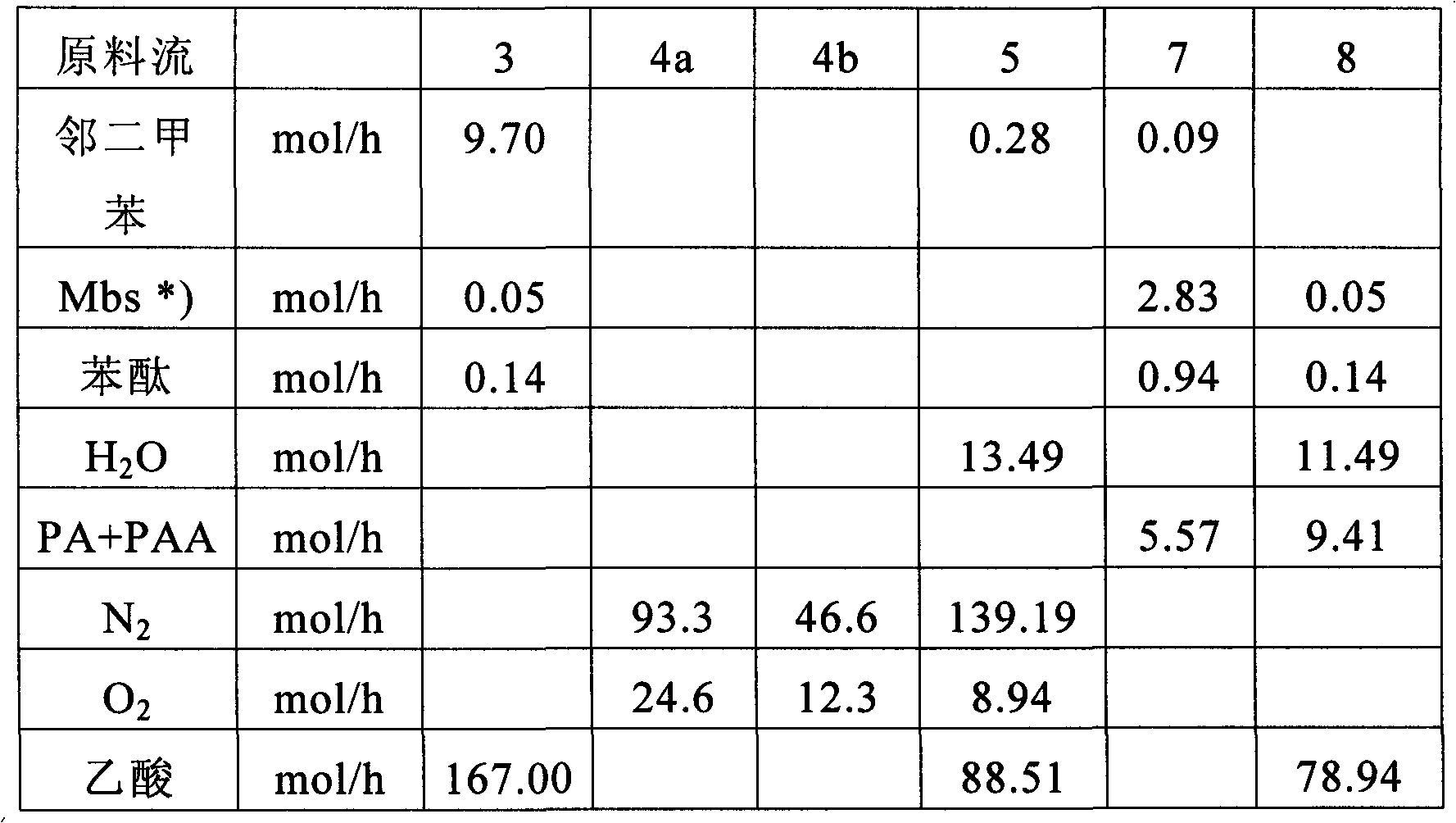

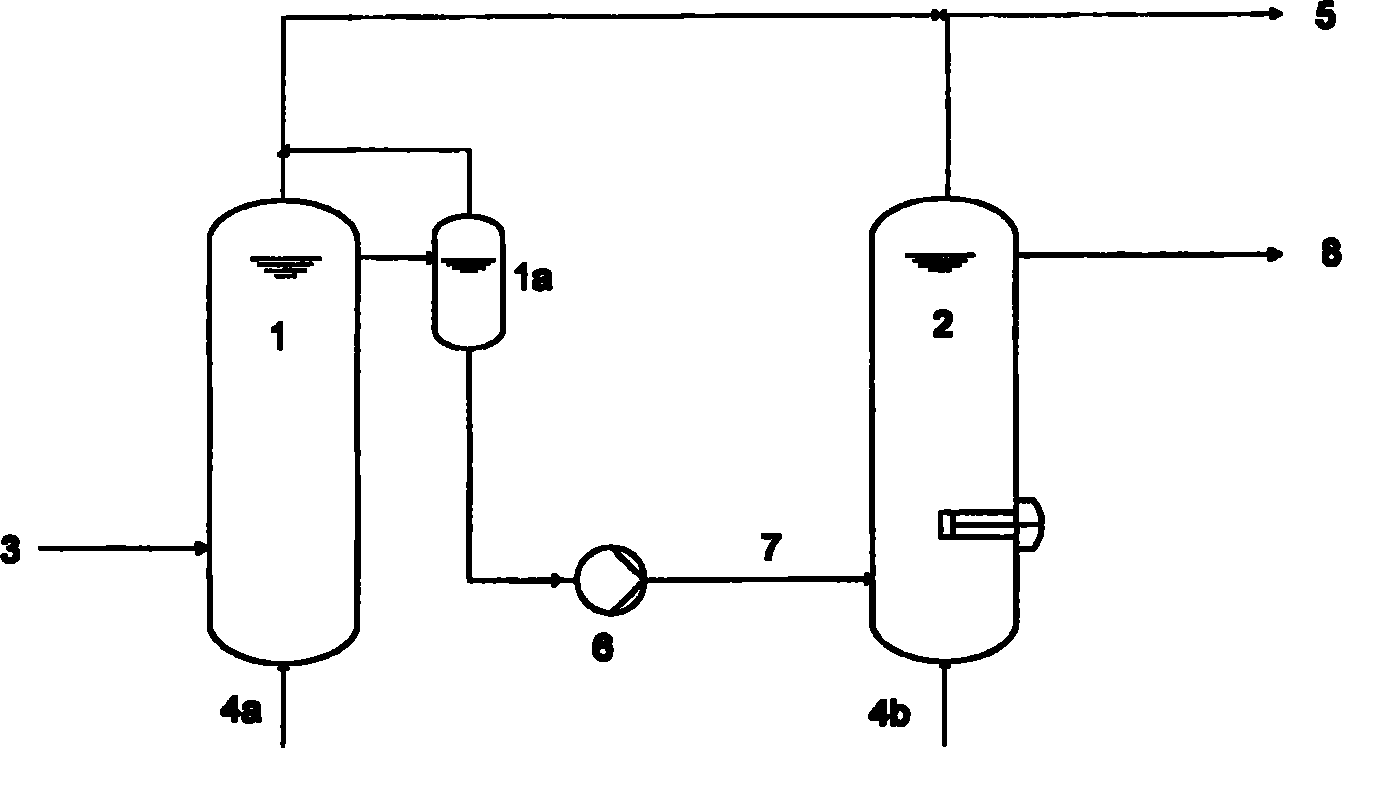

[0023] The process is carried out in two cascade reactors 1 and 2. Reactor 2 is equipped with a heater. Vessel 1 a receives liquid from reactor 1 and acts as a receiver for pump 6 that feeds liquid to reactor 2 . The raw material o-xylene for the oxidation reaction is fed into the first reactor 1 together with the raw material stream 3 . Atmospheric oxygen is introduced into the reactor through feed flow conduits 4a, 4b. Via feed flow conduit 5, off-gas is removed from reactors 1, 2 and vessel 1a. Since prior to use in Reactor 1, outside of this process, it has been used as an extractant to remove intermediates from PA / PAA, which contains a total of 1.9 mole % of 2-methylbenzaldehyde, 2-methylbenzene Formic acid and phthalides.

[0024] Dissolve o-xylene in acetic acid at a molar ratio of 1:17.2. In feed stream 3, salts of the elements cobalt, manganese, bromine and zirconium must be added as catalysts. The molar ratio of o-xylene to cobalt is 1:0.01. The molar ratio of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com