Water treatment method and water treatment flocculant

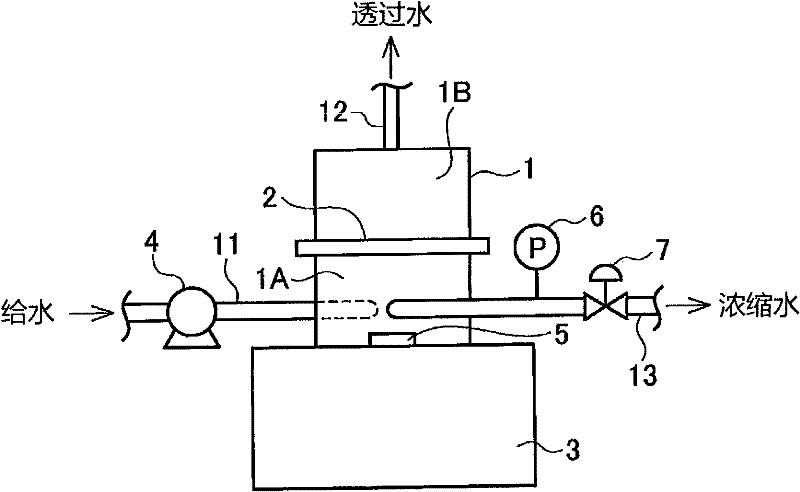

A water treatment and coagulant technology, applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. The effect of reducing the amount of water, realizing the membrane separation treatment, and improving the membrane fouling index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

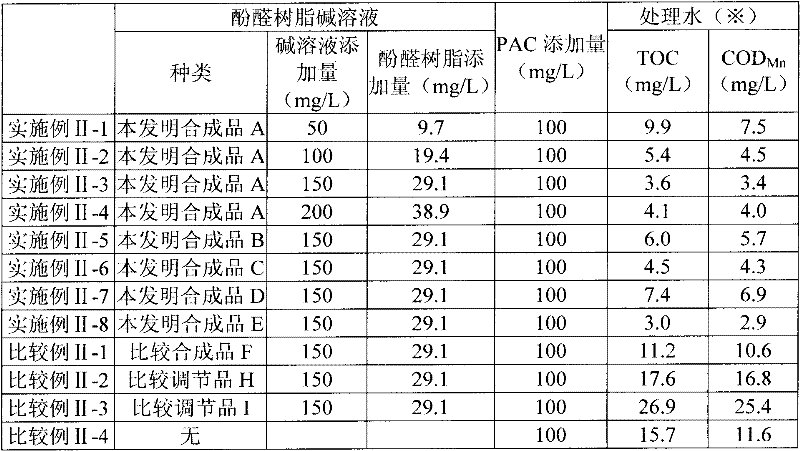

Examples

Embodiment

[0134] Hereinafter, the present invention will be described more specifically by giving examples.

[0135] In addition, "%" below shows "weight%".

[0136] In addition, hereinafter, for a sample prepared according to the above-mentioned , the melting point measured according to the above-mentioned is simply referred to as "melting point", and the catalog data value of the resin or not The melting point measured by dissolving the sample resin in an alkali solution is called "primary resin melting point".

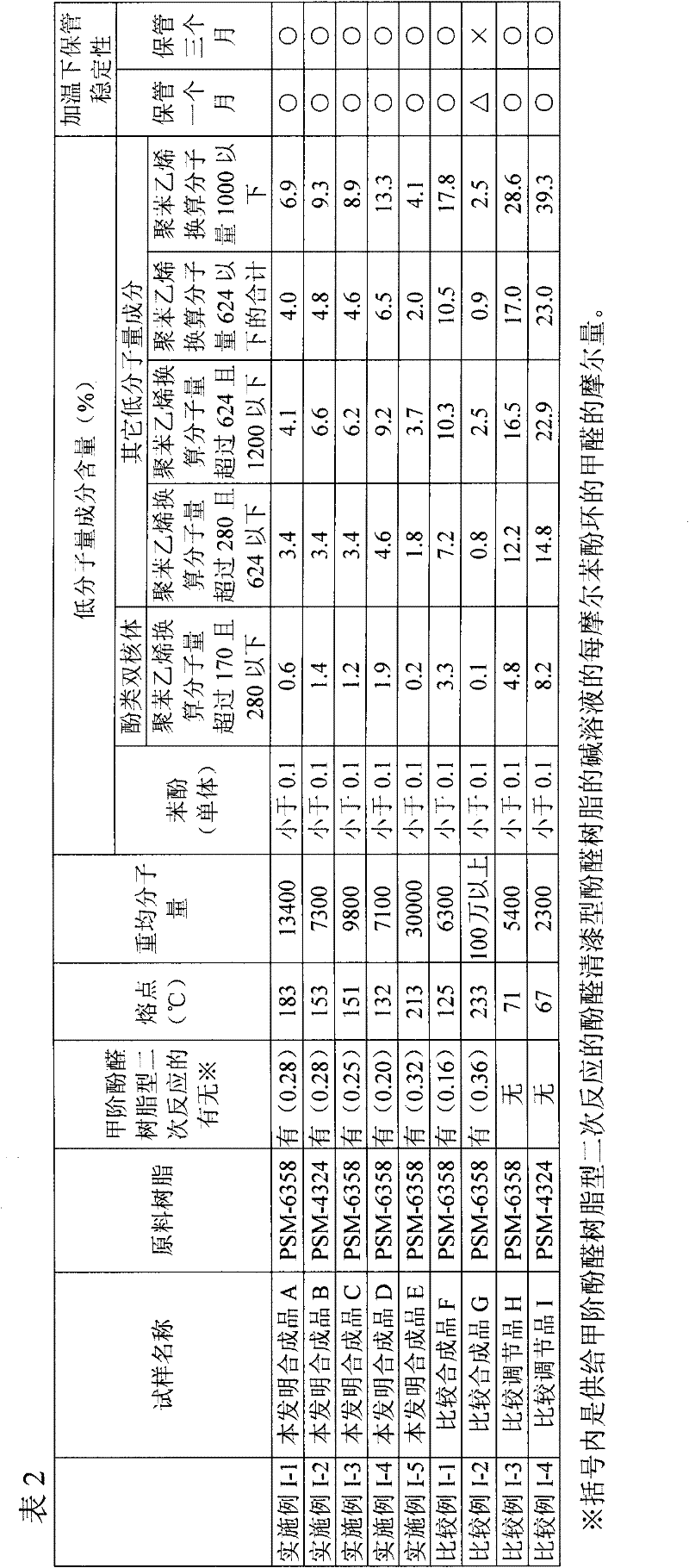

[0137] [Manufacture of secondary reaction phenolic resin alkali solution]

[0138] As raw material resins, "Reyototsup PSM-6358 and PSM-4324" manufactured by Qunei Chemical Industry Co., Ltd. were used. This product is a novolac type phenolic resin obtained by polycondensing phenol and formaldehyde in the presence of an acid catalyst. Melting point, weight average molecular weight, low molecular weight component content, etc. are shown below.

[0139] Table 1

[0140] ...

Embodiment I-1

[0143] Put 41g of PSM-6358, 146.2g of ion-exchanged water and 12.8g of 48% sodium hydroxide aqueous solution in a beaker, stir and dissolve with a magnetic stirrer, and obtain 200g of novolak-type phenolic resin base containing 20.5% of PSM-6358 solution. The pH of the solution was 12.4.

[0144] Put 100g of PSM-6358 lye into a 200mg / L Erlenmeyer flask with stopper (co-embolization), add 4.43g of 37% formaldehyde aqueous solution after heating to about 60°C, spray the condenser and stirring with nitrogen The tube and the thermometer were installed on the plug, and the formaldehyde addition polycondensation reaction of the resole type was carried out at a liquid temperature of 85° C. through an oil bath for 8 hours (secondary reaction of the resole type). In addition, the amount of formaldehyde used here is equivalent to 28 mol% (PSM-6358 is 20.5g, 20.5÷106=0.193mol; formaldehyde is 4.43×0.37 = 1.64 g, 1.64 ÷ 30 = 0.055 mol, therefore 0.055 ÷ 0.193 = 0.28). Then, this was co...

Embodiment I-2

[0146] Except for using PSM-4324 instead of PSM-6358, the same operation was performed as in Example I-1 to obtain a secondary reaction phenolic resin alkali solution (hereinafter referred to as "synthetic product B of the present invention").

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| aperture size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com