Detection method for molecular weight of polyethylene

A measurement method, polyethylene technology, applied in the direction of measuring devices, analysis materials, flow characteristics, etc., can solve problems such as limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] This method is applicable to the dynamic rheometer of various models, and the used instrument of the present invention is:

[0043] (1) AR-G2 dynamic rheological analyzer produced by American TA company

[0044] Frequency range: 7.54×10 -7 ~628.3rad / s, temperature range: -150~400℃

[0045] (2) Shanghai Puda Hydraulic Machinery Manufacturing Co., Ltd. produces XLB-0.25D / Q flat vulcanizing machine

[0046] Pressure: 0~16MPa, Temperature: 0~300℃

[0047] 1.1 Test sample preparation

[0048] In a flat vulcanizing machine, use a mold at 180°C to press the granular polyethylene sample 1# into a disc with a diameter of 25 mm and a thickness of 2 mm, which is uniform, free of bubbles, and has a clean and flat surface.

[0049] 1.2 Test steps

[0050] (1) Turn on the compressed air and adjust the inlet pressure of the rheometer to 30psi;

[0051] (2) Open the safety lock of the rheometer;

[0052] (3) AR-G2 rheometer main engine is turned on, and after the instrument pass...

Embodiment 2

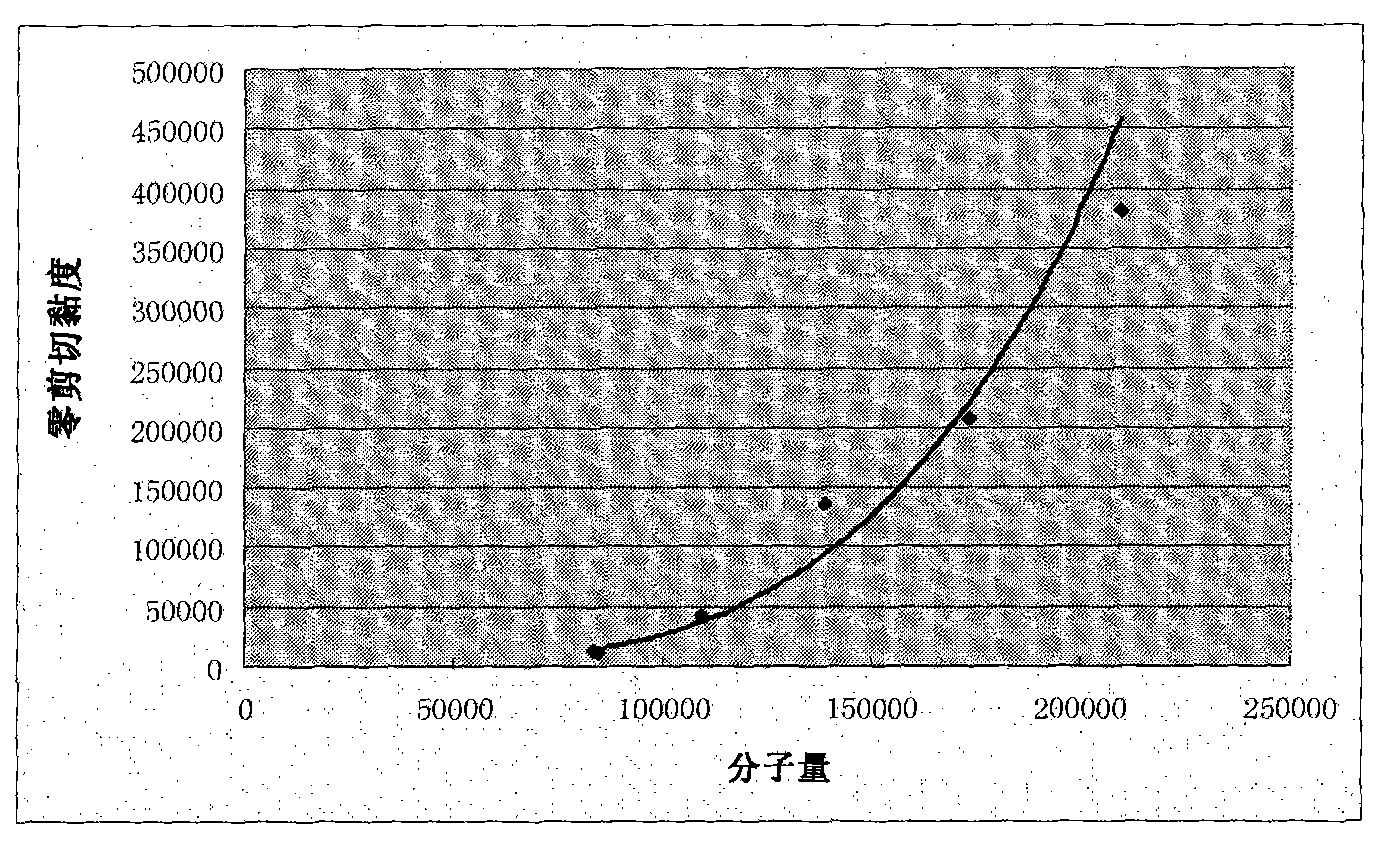

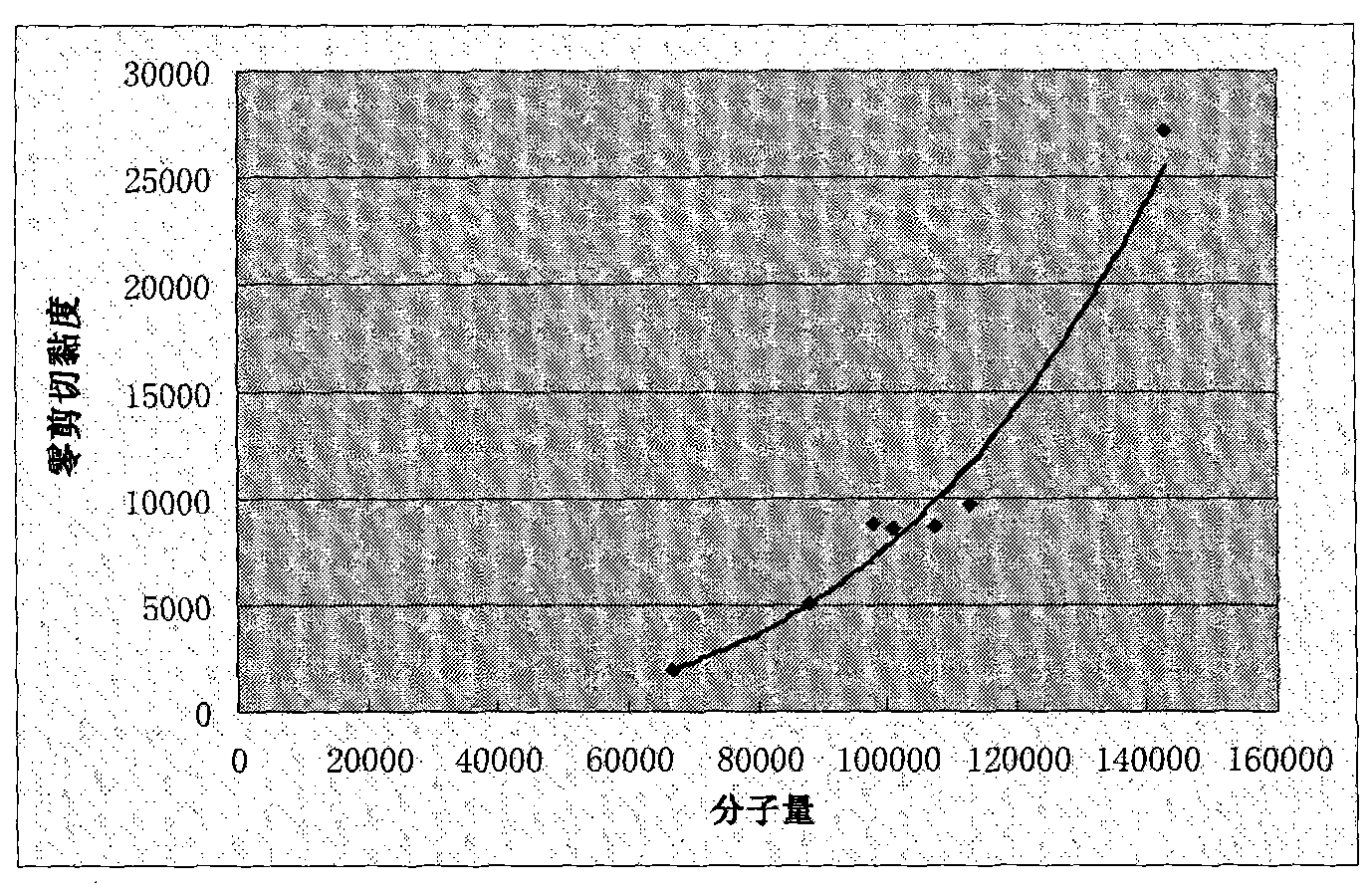

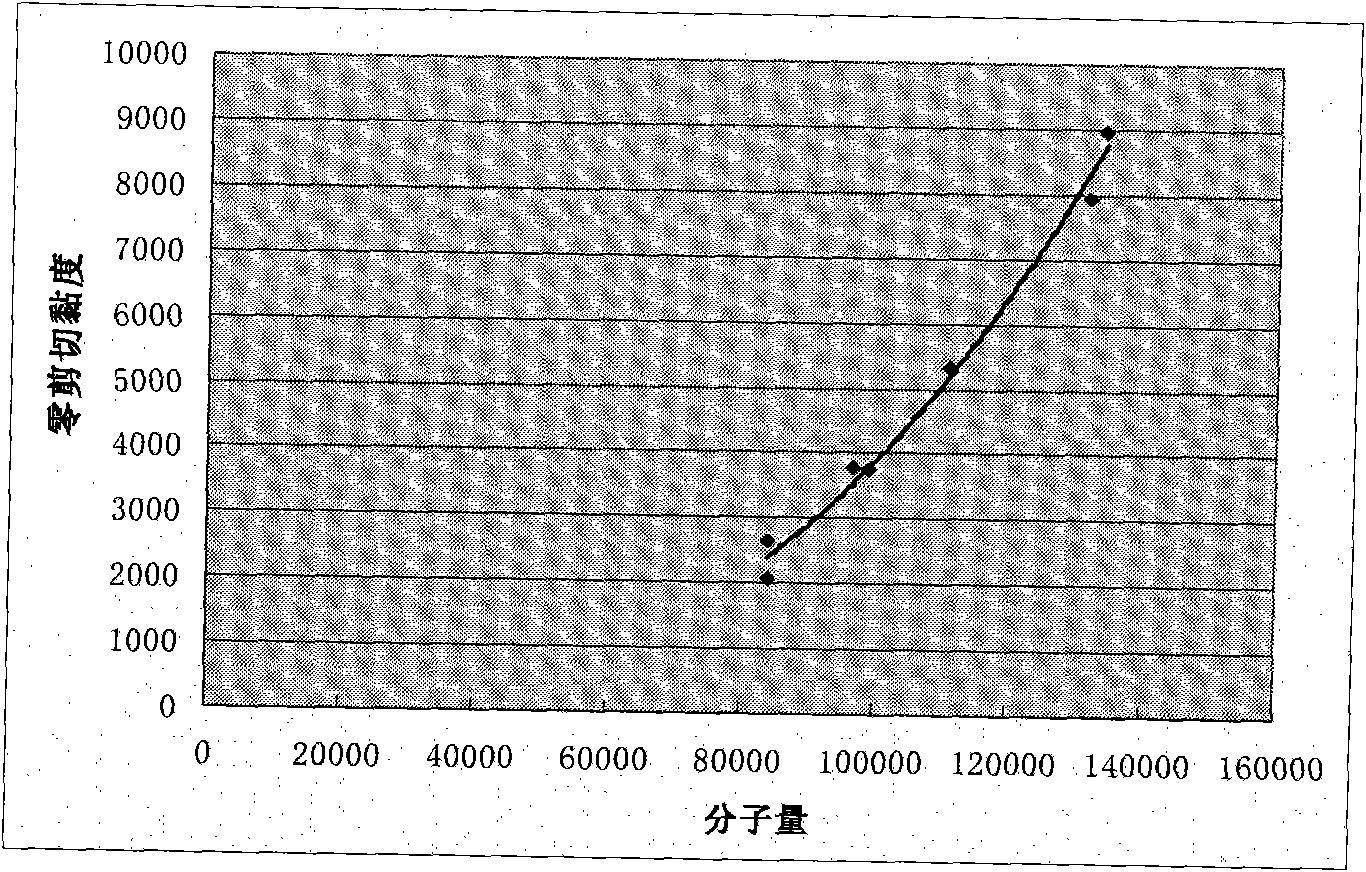

[0066] According to the method of Example 1, the rheological test and calculation were carried out on the powdered polyethylene sample 2#, and the sample was determined to belong to the polyethylene H category according to the RSI. The results are shown in Table 2. The GPC test method used to verify the reliability of the method of the present invention is the same as in Example 1, and the results are shown in Table 2.

Embodiment 3

[0068] According to the method of Example 1, the granular polyethylene sample 3# was subjected to rheological tests and calculations. According to the RSI, it was determined that the sample belonged to the polyethylene L category. The results are shown in Table 2. The GPC test method used to verify the reliability of the method of the present invention is the same as in Example 1, and the test results are shown in Table 2.

[0069] Sample test and calculation result in the embodiment of table 2

[0070]

[0071] As can be seen from Table 2, the same polyethylene sample is very close to the molecular weight measured by the method of the present invention and GPC, indicating that the method of the present invention can be effectively used to measure the molecular weight of polyethylene.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com