Preparation method for TEM sample

A sample and sample technology, applied in the field of TEM sample preparation, can solve problems such as difficult TEM analysis and indistinguishability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

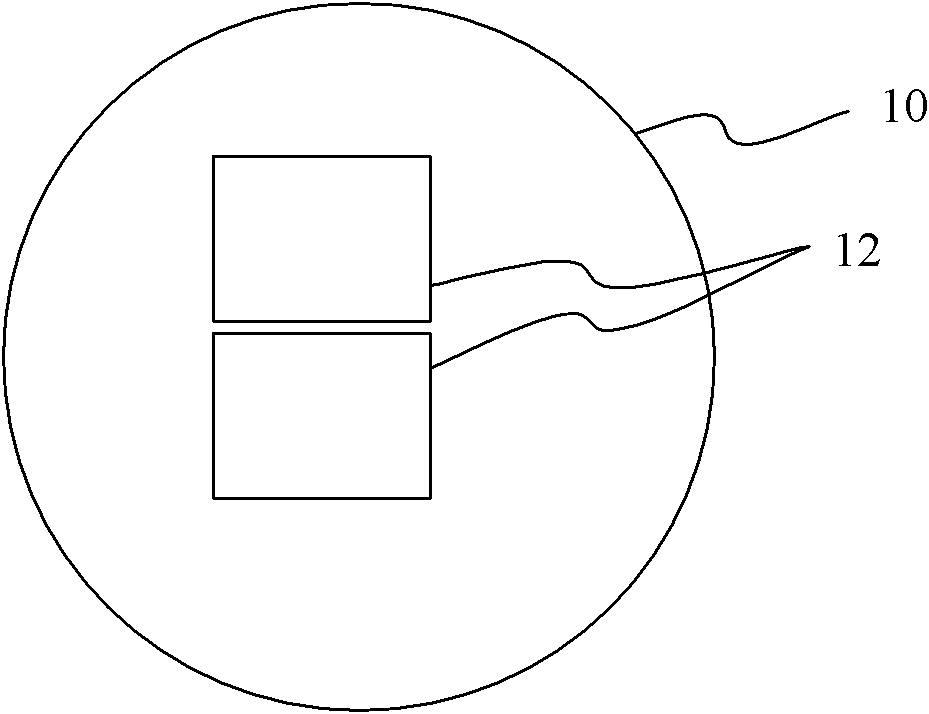

[0037] Figure 7It is a flowchart of the preparation method of the TEM sample of the present invention. Such as Figure 7 Shown, the preparation method of TEM sample of the present invention comprises steps:

[0038] S10, providing a detection sample, the detection sample has at least two regions to be detected, that is, a first region to be detected and a second region to be detected;

[0039] S20, forming a mark on the first region to be detected of the detection sample;

[0040] S30, cutting out a first sample from the first area to be detected, the first sample including the mark, cutting out a second sample from the second area to be detected, the shape of the second sample and The shape of the first sample is the same;

[0041] S40, adhering one side of the first sample and the second sample with the area to be detected is bonded to form a double sample;

[0042] S50, thinning the double swatch along two opposite sides of the cut swatch until the mark is exposed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com