Preparation method of micron-scale flower-like combined metal oxide

A composite metal, micron-scale technology, applied in chemical instruments and methods, single crystal growth, polycrystalline material growth and other directions, can solve problems such as reports that have not yet appeared

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

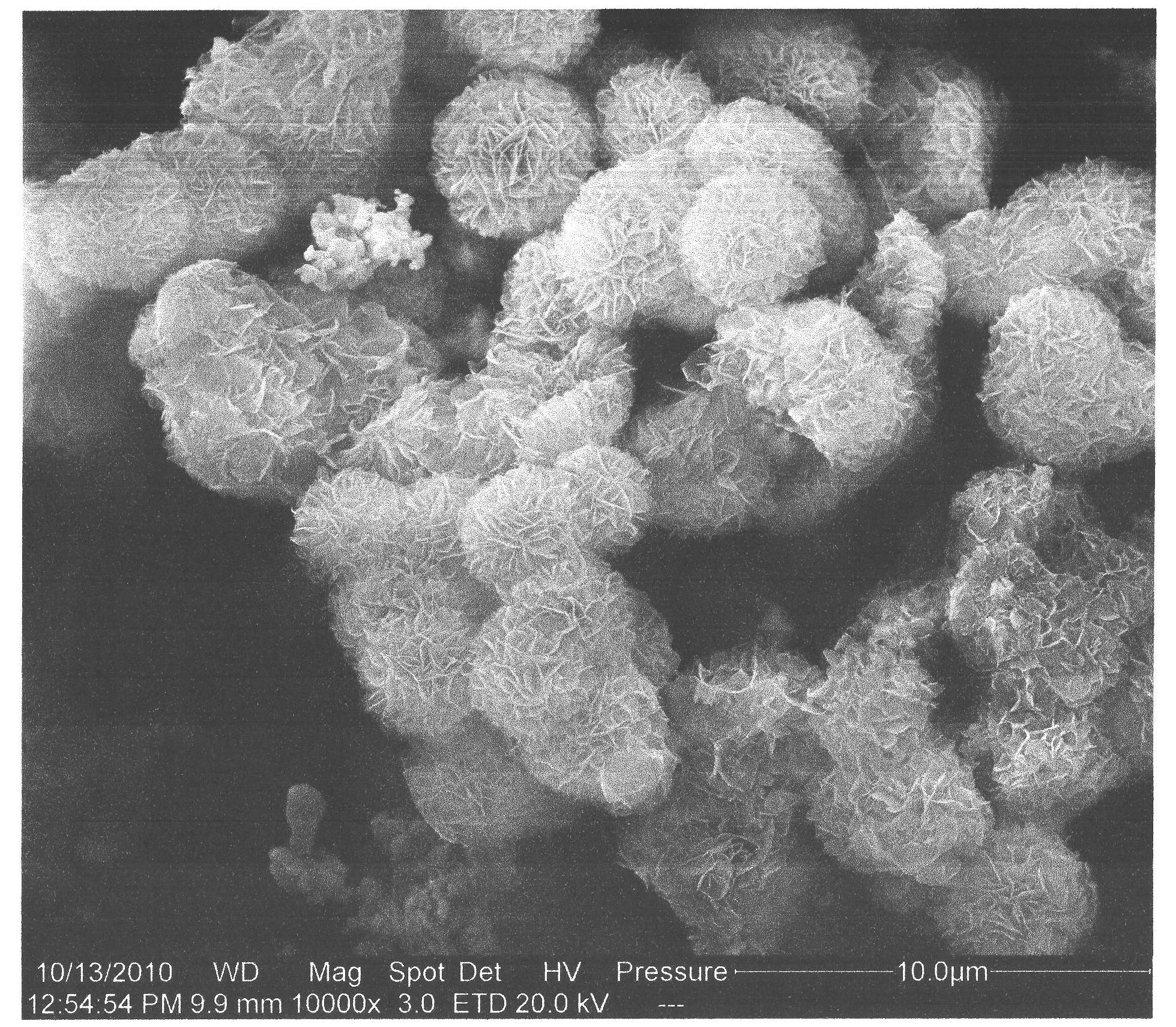

[0022] According to the technical solution of the present invention, 0.356g of 50% wt. manganese nitrate aqueous solution and 0.146g of cobalt nitrate were added to 42mL of ethylene glycol under magnetic stirring at room temperature, and magnetic stirring was used to form a uniform solution. Add 11.9g of polyvinylpyrrolidone to the homogeneous solution, and stir the solution until it becomes transparent. Add 2.93 g of sodium acetate, and stir for 3 hours. Then put it into a closed container (60 mL) for solvothermal reaction, and react at 200° C. for 2 hours. After cooling to room temperature, washing with deionized water and absolute ethanol, drying in a vacuum oven at 50° C. for 6 hours, the product can be obtained as a micron-sized flower-shaped composite metal basic carbonate. The product is put into a reaction furnace and calcined at 350° C. for 2 hours to prepare a micron-sized flower-shaped composite metal oxide. The morphology of the product is detected by a scanning ...

Embodiment 2

[0024] According to the technical solution of the present invention, 0.356g of 50% wt. manganese nitrate aqueous solution and 0.291g of cobalt nitrate were added to 42mL of ethylene glycol under magnetic stirring at room temperature, and magnetic stirring was used to form a uniform solution. Add 5.9g of polyvinylpyrrolidone to the homogeneous solution, and stir the solution until it becomes transparent. 0 g of sodium acetate was added and stirred for 1 hour. Then put it into a closed container (60 mL) for solvothermal reaction, and react at 120° C. for 24 hours. After cooling to room temperature, washing with deionized water and absolute ethanol, drying in a vacuum oven at 50° C. for 6 hours, the product can be obtained as a micron-sized flower-shaped composite metal basic carbonate. The product is put into a reaction furnace and calcined at 300° C. for 4 hours to prepare a micron-sized flower-shaped composite metal oxide. The appearance of the product is detected by a scann...

Embodiment 3

[0026] According to the technical solution of the present invention, 0.353g of manganese chloride and 0.249g of nickel acetate are respectively added to 32mL of ethylene glycol at room temperature, and magnetically stirred to form a uniform solution. Add 11.9g of polyvinylpyrrolidone to the homogeneous solution, and stir the solution until it becomes transparent. Add 2.93 g of sodium acetate, and stir for 3 hours. Then put it into a closed container (60 mL) for solvothermal reaction, and react at 200° C. for 2 hours. After cooling to room temperature, washing with deionized water and absolute ethanol, drying in a vacuum oven at 50° C. for 6 hours, the product can be obtained as a micron-sized flower-shaped composite metal basic carbonate. The product is put into a reaction furnace and calcined at 400° C. for 5 hours to prepare a micron-sized flower-shaped composite metal oxide. The morphology of the product is detected by a scanning electron microscope: flowers with a diamet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com