Energy-saving integrated intelligent soft porcelain insulation board production line

A technology of intelligent production and thermal insulation board, which is applied in the production field of soft porcelain thermal insulation integrated materials, can solve the problems of uneven external thermal insulation finish layer, time-consuming and labor-consuming, high labor cost, etc., and achieve simple structure, good production quality, The effect of high production efficiency

Inactive Publication Date: 2013-09-18

江苏合美软瓷有限公司

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] In the prior art, the external thermal insulation finish layer of the exterior wall is generally set manually. Therefore, it is not only time-consuming and labor-intensive, but also the labor cost is high, and there is unevenness of the external thermal insulation finish layer in manual application.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

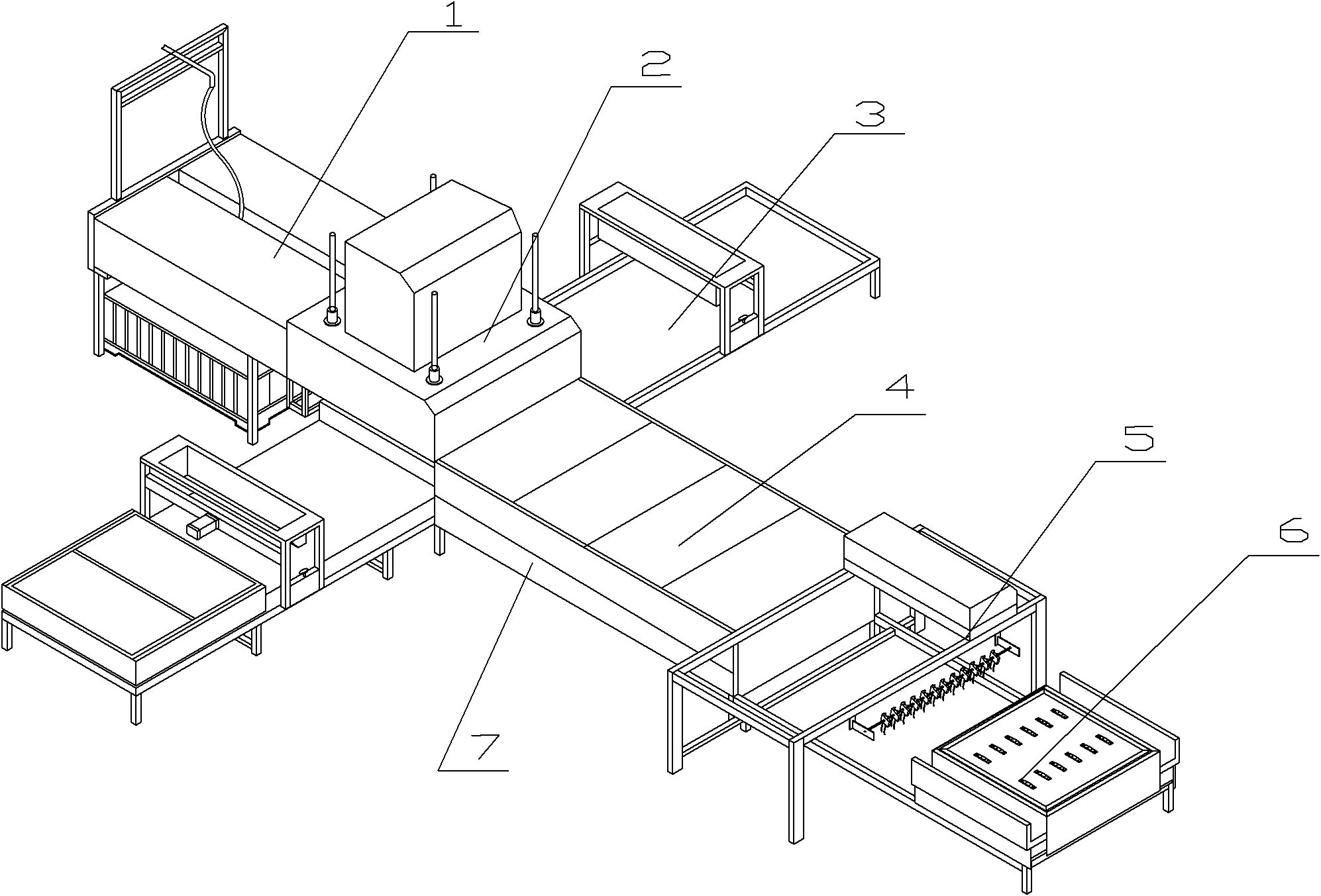

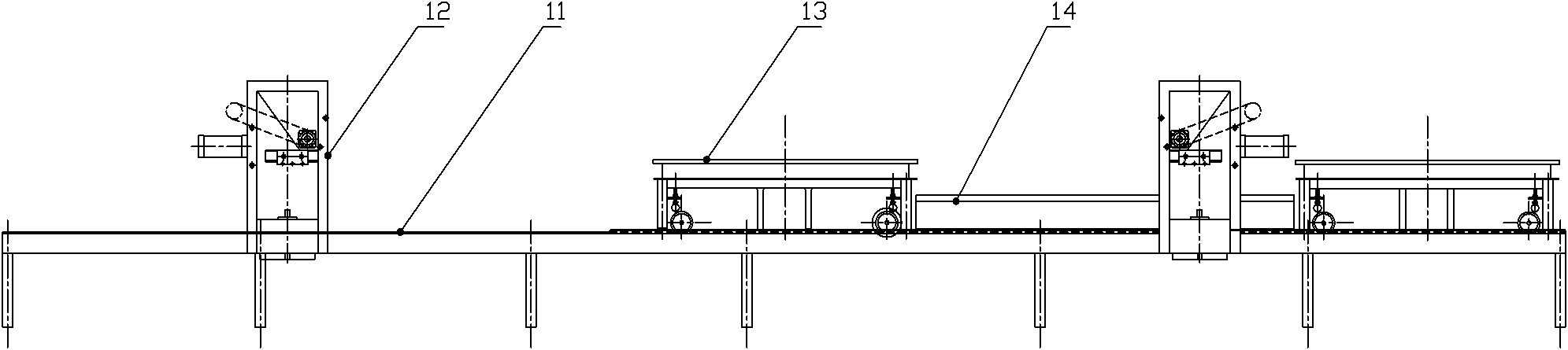

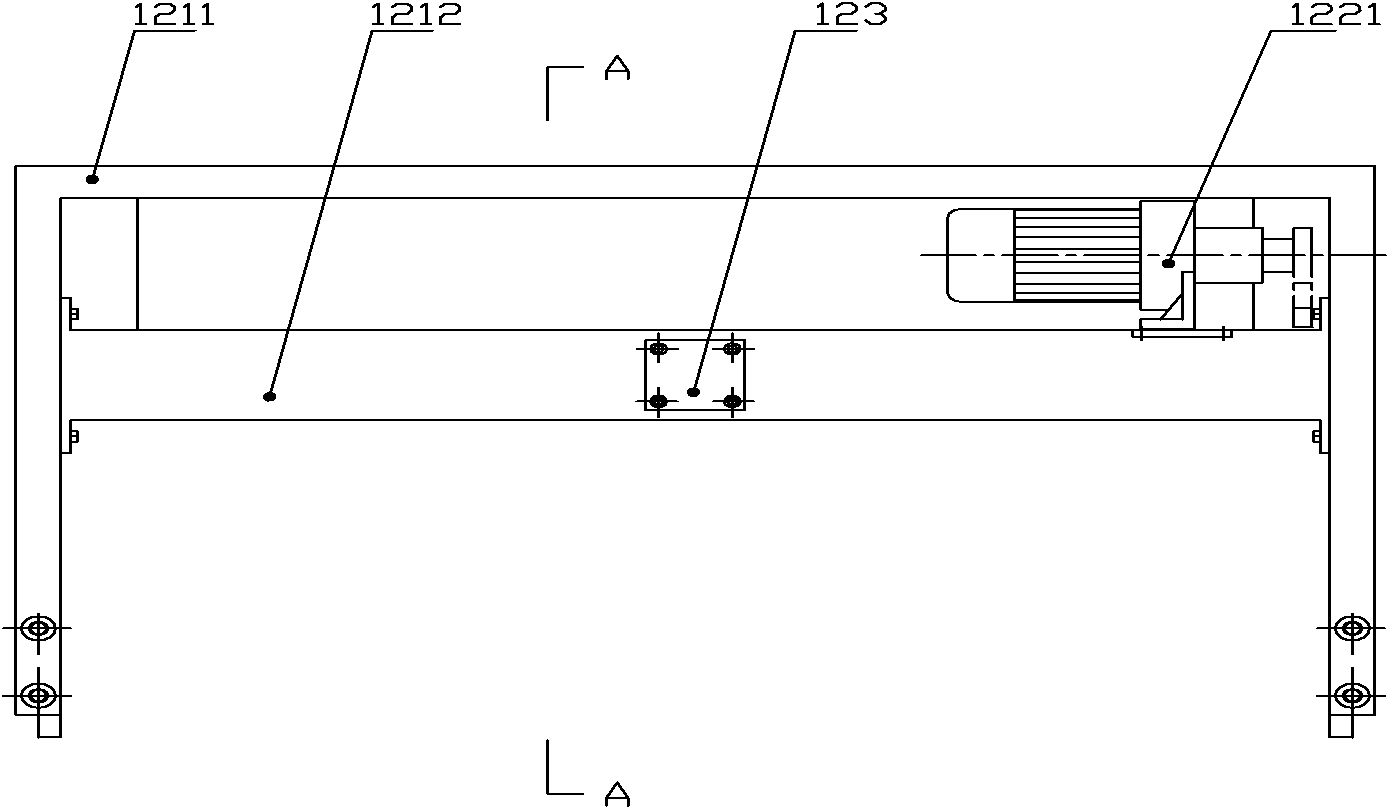

The invention discloses an energy-saving integrated intelligent soft porcelain insulation board production line, which comprises a base, a scraping unit, a porcelain suction unit, a porcelain-pressing unit, a predrying unit, a pointing unit and a discharge unit, and the scraping unit, the porcelain suction unit, the porcelain-pressing unit, the predrying unit, the pointing unit and the discharge unit are respectively mounted on the base; the scraping unit is adopted to scrap slurry on insulation boards; the porcelain suction unit is adopted to suck soft porcelain and spread the soft porcelain powder on the insulation boards; the porcelain-pressing unit is adopted to press the soft porcelain and the insulation boards to be shaped; the predrying unit is adopted to predry the integrated soft porcelain insulation materials, so that the pointing requirement can be met; the pointing unit is adopted for pointing, so that finished soft porcelain insulation board products are produced, and finally, the finished soft porcelain insulation board products are conveyed into a finished product warehouse by the discharge unit. Consequently, the production line can be used for automatically producing soft porcelain insulation boards, the production efficiency is high, the production quality is good, and moreover, the production line has a simple structure, and is easy to put into practice.

Description

technical field [0001] The invention relates to a production equipment for soft porcelain thermal insulation boards, which is mainly used in the production of soft porcelain thermal insulation integrated materials. Background technique [0002] In the prior art, the external thermal insulation finish layer of the exterior wall is generally set manually. Therefore, it is not only time-consuming and labor-intensive, but also has high labor costs, and the manual application has unevenness of the external thermal insulation finish layer. The production of soft porcelain insulation board generally includes the following steps: spreading and scraping slurry on the insulation material; vacuuming soft porcelain and laying it on the insulation material; extruding the soft porcelain material and insulation material; The formed soft porcelain thermal insulation integrated material is pre-dried; finally, the jointing operation is performed to obtain the finished product. Therefore,...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B28B1/29B28B3/20

Inventor 董金明

Owner 江苏合美软瓷有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com