A fully automatic plastic injection mold for new energy auto parts

A technology for new energy vehicles and plastic injection molds, applied in the field of injection molds, can solve the problems of high surface temperature of products, a lot of manpower, hot hands, etc., to improve production efficiency, save manpower, and avoid contact burns.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

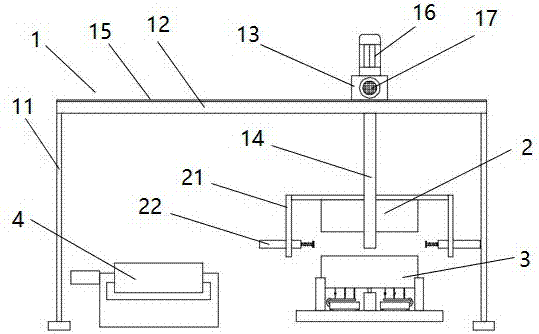

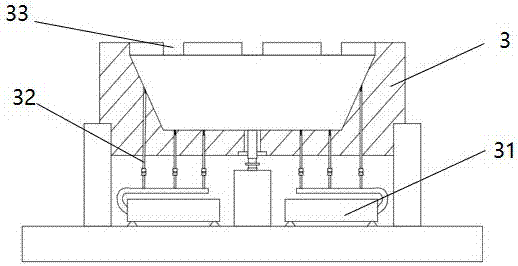

[0024] Embodiment 1: A fully automatic plastic injection mold for new energy automobile parts, including a frame, an upper module, a lower module and a conveying line, the frame includes a support column, a guide rail, a movable beam and a mechanical arm; the support column There are four; the guide rails are two, and are arranged in parallel on the top of the support column; the movable beam is arranged on the upper ends of the two guide rails, and can move along the guide rails; the mechanical arm is arranged on the movable beam; the upper module It is connected with the mechanical arm, and the upper module can move up and down along the mechanical arm; the lower module and the conveying line are arranged side by side under the frame; an injection cavity can be formed between the upper module and the lower module; the upper part of the upper module An upper heating plate is provided; a lower heating plate is provided below the lower module.

Embodiment 2

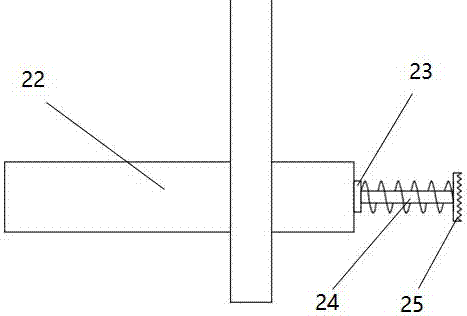

[0025] Embodiment 2: A fully automatic plastic injection mold for new energy automobile parts, including a frame, an upper module, a lower module and a conveying line, the frame includes a support column, a guide rail, a movable beam and a mechanical arm; the support column There are four; the guide rails are two, and are arranged in parallel on the top of the support column; the movable beam is arranged on the upper ends of the two guide rails, and can move along the guide rails; the mechanical arm is arranged on the movable beam; the upper module It is connected with the mechanical arm, and the upper module can move up and down along the mechanical arm; the lower module and the conveying line are arranged side by side under the frame; an injection cavity can be formed between the upper module and the lower module; the upper part of the upper module An upper heating plate is provided; a lower heating plate is provided under the lower module, and a toothed bar is provided on th...

Embodiment 3

[0026] Embodiment 3: A fully automatic injection mold for new energy automobile parts, including a frame, an upper module, a lower module and a conveying line, the frame includes a support column, a guide rail, a movable beam and a mechanical arm; the support column There are four; the guide rails are two, and are arranged in parallel on the top of the support column; the movable beam is arranged on the upper ends of the two guide rails, and can move along the guide rails; the mechanical arm is arranged on the movable beam; the upper module It is connected with the mechanical arm, and the upper module can move up and down along the mechanical arm; the lower module and the conveying line are arranged side by side under the frame; an injection cavity can be formed between the upper module and the lower module; the upper part of the upper module An upper heating plate is provided; a lower heating plate is provided below the lower module, and a second servo motor is provided on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com