Automatic feeding device and operation method for a punching machine

An automatic feeding and punching technology, applied in storage devices, feeding devices, positioning devices, etc., can solve problems such as increased labor intensity, decreased production efficiency, safety accidents, etc., to reduce labor intensity, improve production efficiency, and reduce safety accidents Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

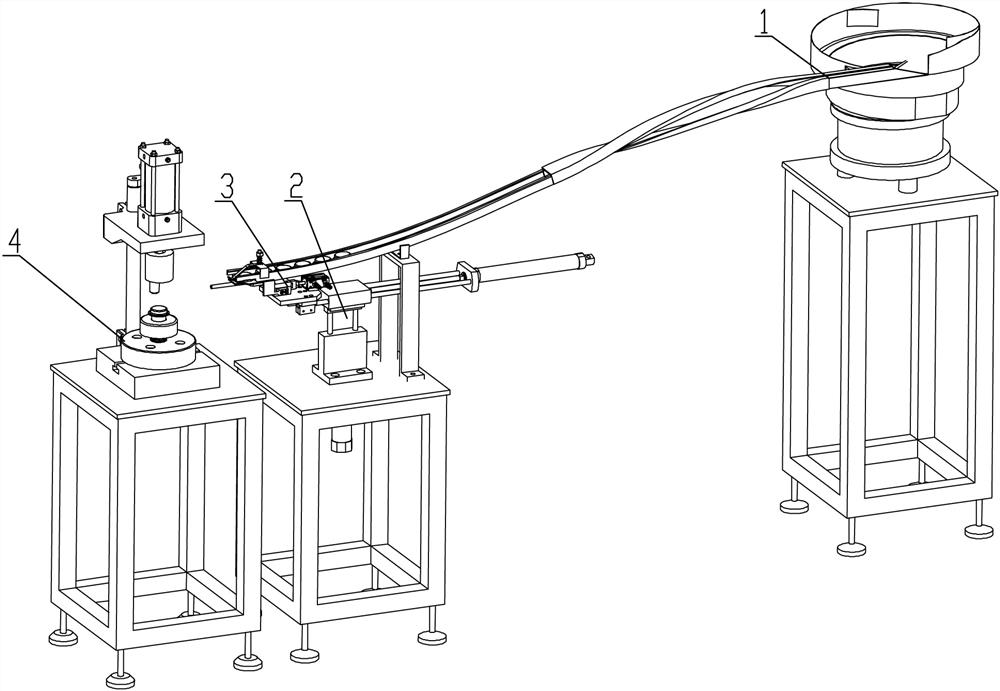

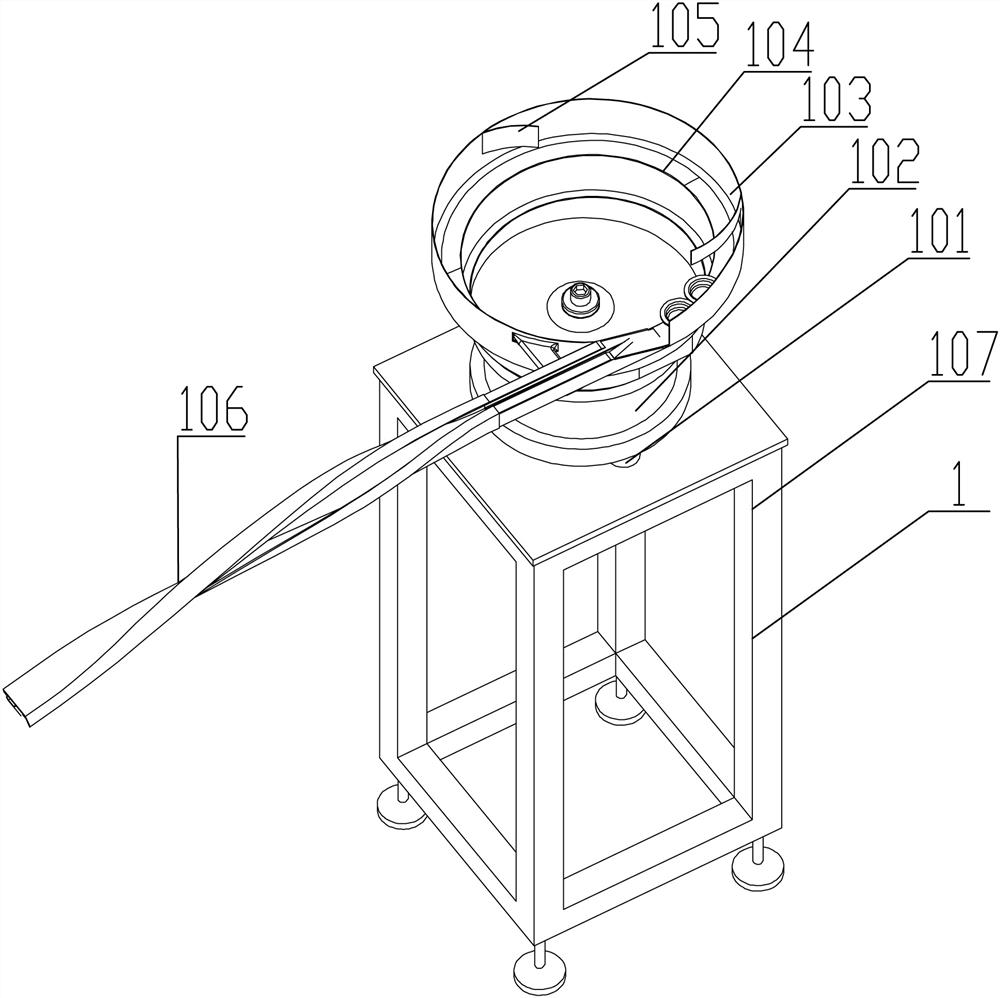

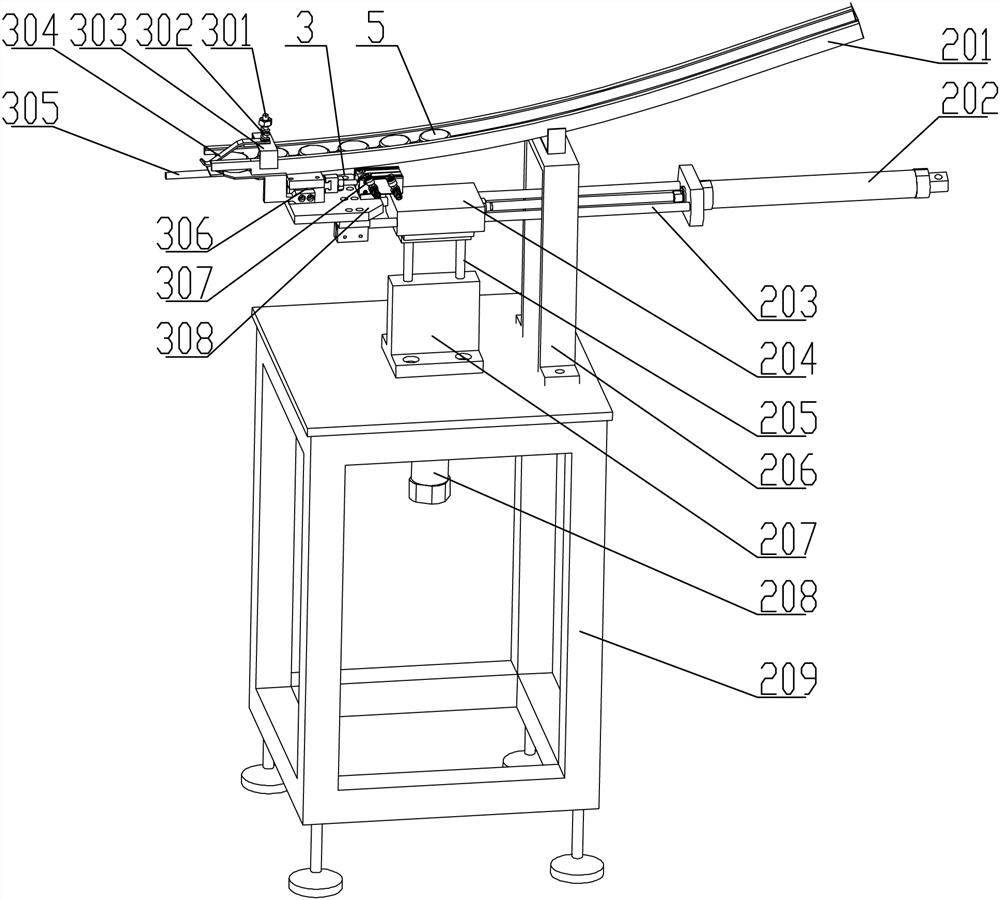

[0039] see Figure 1-4 , an automatic feeding device for a punching machine, which includes an automatic feeding mechanism 1 for automatic feeding and discharging of raw materials to be punched, the end of the automatic feeding mechanism 1 is docked with a discharging mechanism 3 for discharging, the discharging The material mechanism 3 is installed on the material retrieving mechanism 2 for material pushing, and the side of the material reclaiming mechanism 2 is provided with a stamping mechanism 4 for material stamping. By adopting the above structure and using the characteristics of vibrating plate material selection, the profile with a specific posture is selected from the messy cover-shaped raw materials, and then the profile is picked up by the retrieving manipulator and placed on the punching machine for stamping and deep drawing, thus achieving full-automatic ways to produce. This equipment can replace manual operation, greatly reduces the labor intensity of workers, ...

Embodiment 2

[0052] The using method of described punch automatic feeding device, it comprises the following steps:

[0053] Step1: Place the raw material to be punched inside the hopper 103 of the automatic feeding mechanism 1, and start the vibration main body 102, and discharge the cover-shaped raw material 5 to be punched by the spiral track 104 through the vibration main body 102, and in the direction selection mechanism 105 Under the action of the hopper, only the cover-shaped raw material 5 with the concave surface upward can pass through, and the raw materials in other postures will fall to the bottom of the hopper 103 and rise again;

[0054] Step2: The cap-shaped raw material 5 after being discharged by the automatic feeding mechanism 1 will be transported to the twisting track 106, and when passing through the twisting track 106, it will turn over 180° and become a concave downward state, and then be transported to the discharge through the feeding chute 201 The pick-up point of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com