Wire clamp of grounding wire

A grounding wire clip and splint technology, applied in the direction of connection, conductive connection, electrical component connection, etc., can solve the problem of wrongly electrified hanging grounding wire, etc., to improve the utilization rate, easy to store and carry, and overcome the effects of easy damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

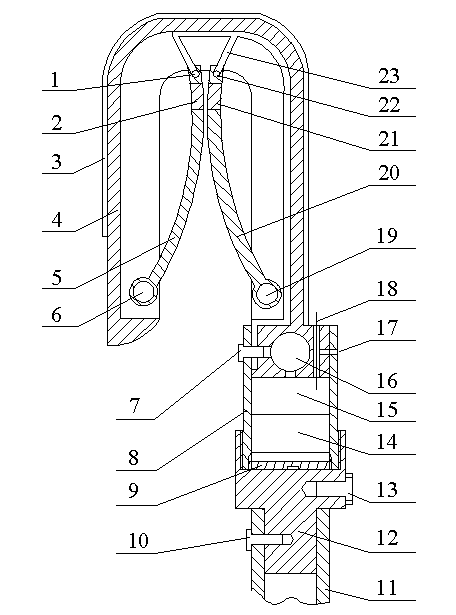

[0014] A grounding wire clamp, comprising an insulating operating rod 11, the insulating operating rod 11 is connected to an aluminum insulating operating rod fixing base 12 through a fixing pin 10, the insulating operating rod fixing base 12 is provided with a grounding wire fixing nut 13, and the insulating operating rod The upper part of the rod fixing base 12 is provided with an aluminum insulating outer bracket fixing base 8, and the lower part of the insulating outer bracket base 8 is provided with a gland 9, and the gland 9 is in contact with the insulating operation rod fixing base 12, and the insulating outer bracket fixing base 8 is provided with Nylon inverted U-shaped insulating outer bracket 4, the probe aluminum strip 3 is installed outside the insulating outer bracket 4, and annealed copper wire 23 is arranged inside the insulating outer bracket 4, and the insulating outer bracket 4 and annealed copper wire 23 are fixed on the On the base 8 of the insulating oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com