Gas tank header part and machining method thereof as well as thermal expansion valve using part

A thermal expansion valve and gas box head technology, applied in the field of thermal expansion valves, can solve the problems of unguaranteed welding quality, small welding contact surface, high processability requirements, etc., to improve welding reliability, reduce thermal influence, and increase area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

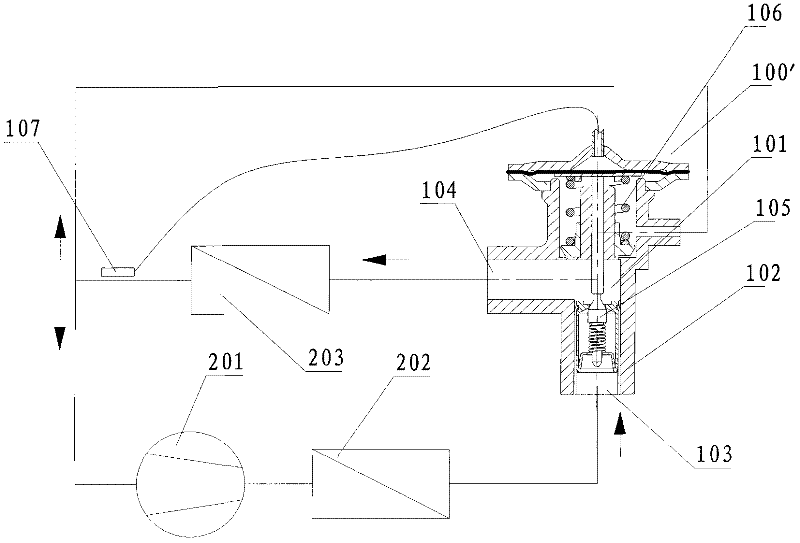

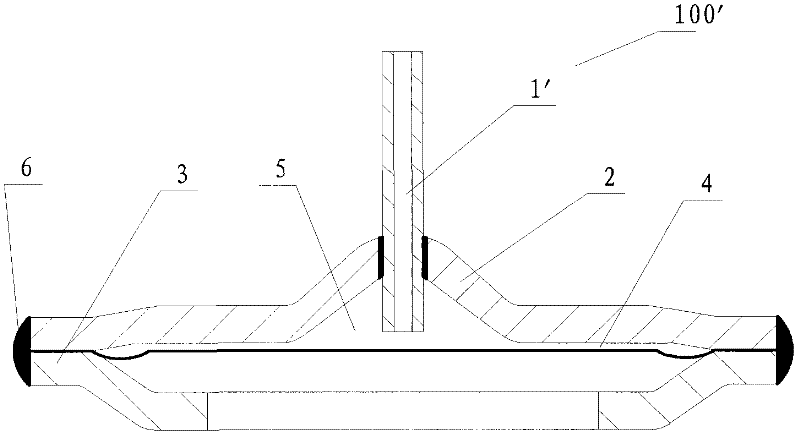

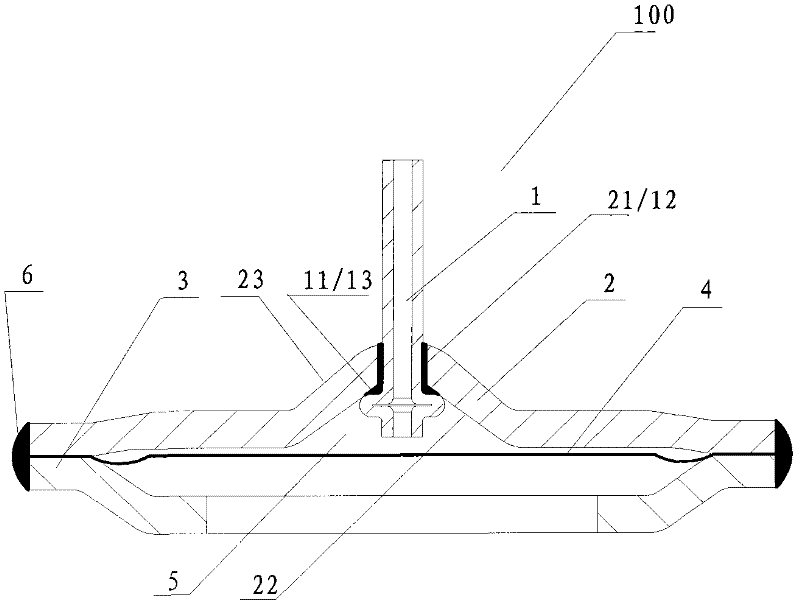

[0041] image 3 A structural schematic diagram of one of the specific embodiments of the thermal expansion valve gas box head part provided for the invention, Figure 8 It is a schematic diagram of the capillary structure in the above embodiment.

[0042] like image 3 and Figure 8 shown and see figure 1 . The thermal expansion valve includes a valve body 102 with an inner cavity 101, a flow channel inlet 103 and a flow channel outlet 104 communicated with the inner cavity 101 of the valve body 102, and an air box head arranged at one end of the valve body 102 A piece 100 and a valve part 104 disposed in the inner chamber 101.

[0043] Air box head part 100 comprises the air box seat body 3 and the air box cover body 2 that are welded into one, diaphragm 4 is arranged between the air box seat body 3 and the air box cover body 2, like this between the air box cover body 2 and the diaphragm An airtight temperature-sensing chamber 5 is formed between the sheets 4 . The ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com