Tensioning device with a cylindrical latching system

A tensioning device, cylinder technology, applied in the direction of transmission, belt/chain/gear, mechanical equipment, etc., to achieve the effect of improving manufacturing quality and manufacturing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

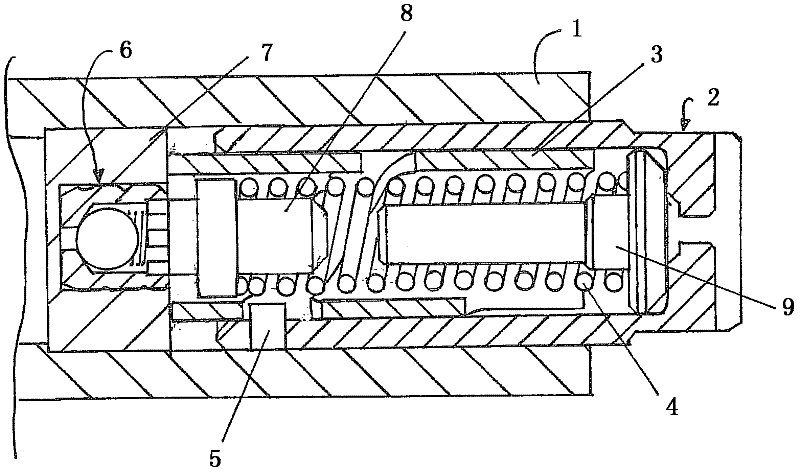

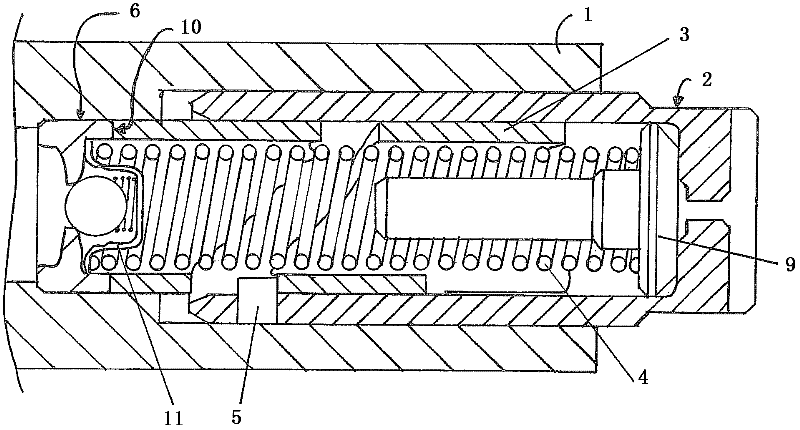

[0020] A tensioning device such as that described in document EP 1 498 580 B1 is shown in FIG. 1 . The piston 2 is mounted slidingly in the housing 1 and serves to tension an endless traction device (not shown) in the engine. Arranged inside the piston 2 is a cylinder 3 in the form of a stop sleeve. The locking sleeve has a helical toothing, into which an engagement element 5 connected to the piston 2 engages in a form-fitting manner. Arranged inside the locking sleeve is a compression spring 4 which bears against the cartridge 8 at a first end and rests on a ventilation plug 9 at a second end. The ventilation plug 9 is assigned to that side of the piston 2 protruding from the housing 1 and allows air to escape from the interior of the piston 2 . The cartridge 8 bears against the non-return valve 6 . In order that oil can flow from an oil supply chamber (not shown) via check valve 6 into the interior of piston 2 , paths, for example flow channels, are provided in the interi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com