Explosion-proof and fire-proof lightweight wall

A light-weight wall and fire-proof board technology, which is applied in the direction of fire protection, wall, and earthquake resistance, can solve the problems of large area occupied by firewalls, poor explosion-proof ability of firewalls, and high construction costs, and achieves convenient restoration, strong adaptability to setting locations, and safety good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Specific embodiments of the present invention will be described in detail below with reference to the drawings.

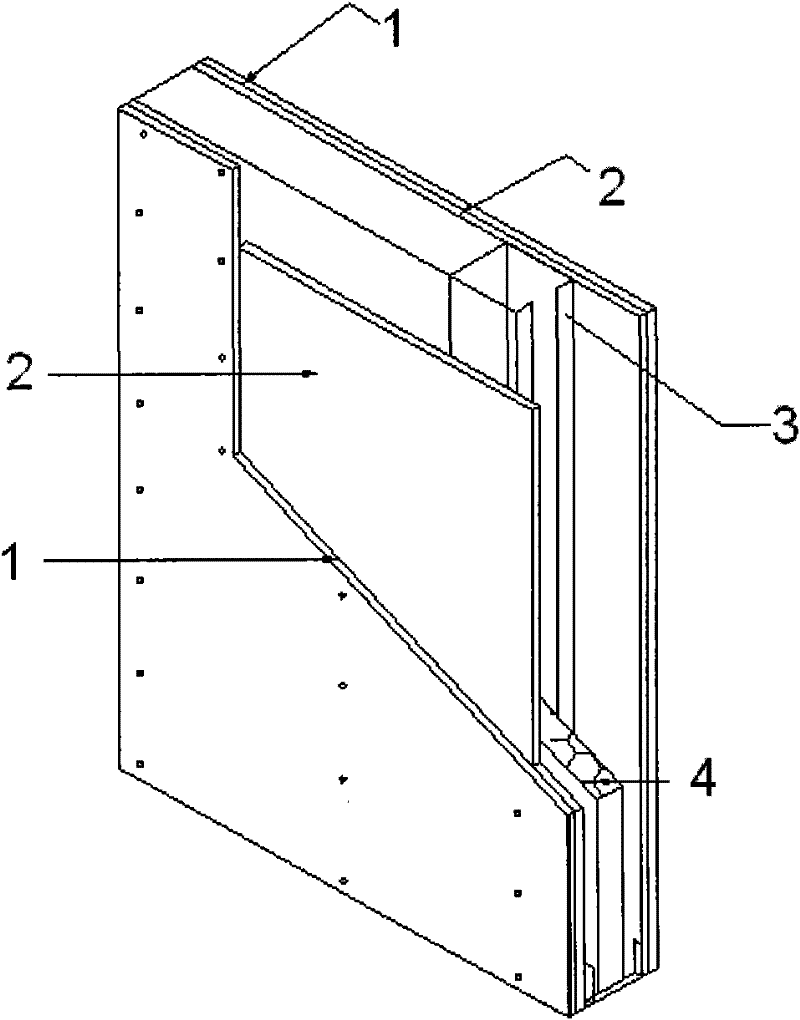

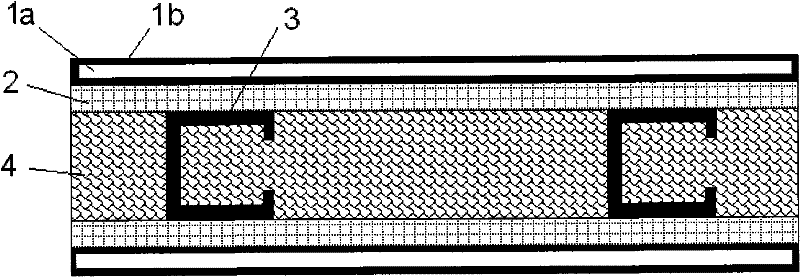

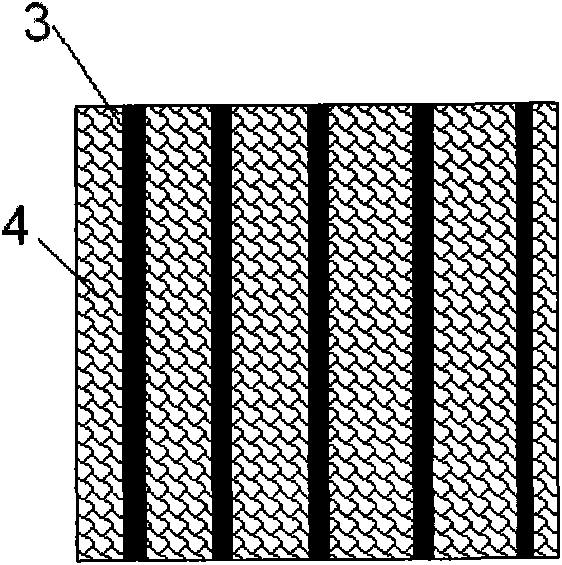

[0020] The purpose of the present invention is to provide an explosion-proof wall that can effectively resist blasting tension and fire-proof and explosion-proof wall when an explosion occurs indoors, and the explosion-proof firewall can effectively resist the outward tension caused by the blasting shock wave and the flame retardant produced thereby. The main structure of the fire-proof and explosion-proof wall of the present invention is composed of an explosion-proof board, a fire-proof board, a keel and fillers. The explosion-proof plate is arranged on the outermost layer, and its material has high impact resistance and can provide excellent resistance to high-pressure jet impact. The fire-proof board is arranged next to the explosion-proof board and is located in the inner layer of the wall, and its chemical composition can be effectively flame-retardant to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com