Method for preparing non-oriented silicon steel with excellent magnetic property and high efficiency

A technology of oriented silicon steel and manufacturing method, applied in the direction of inorganic material magnetism, temperature control, etc., can solve the problems of long manufacturing cycle, difficulty in descaling, high manufacturing cost, etc., and achieve the effect of shortening the manufacturing cycle, reducing consumption, and reducing manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with embodiment.

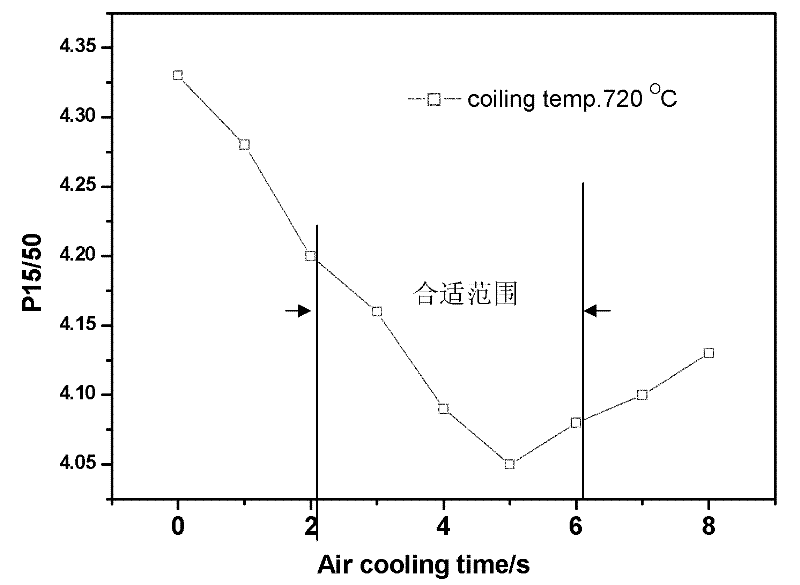

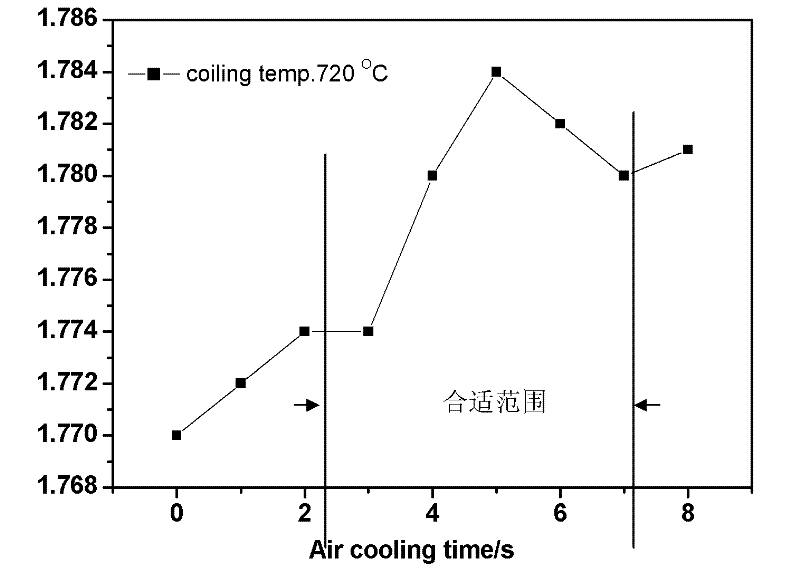

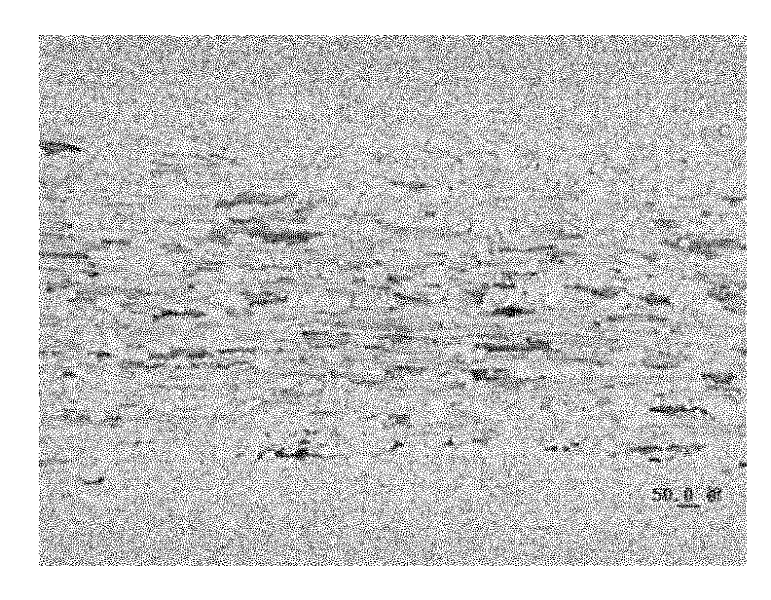

[0040] Smelted according to the components in Table 1, the cast slab is heated, rough rolled, finish rolled, high temperature coiled, pickled, 70-78% reduction rate is once cold rolled to a finished product thickness of 0.5mm, and the cold rolled strip is subjected to different temperatures. The final annealing to the finished product. Table 2 is the result of measuring the chemical composition of steel grades in Table 1 using the production method of the present invention and the finished Epstein square circle.

[0041] Table 1 embodiment chemical composition (%)

[0042] C

Si

mn

P

S

Al

N

Ti

Sb

Example 1

0.0009

0.23

0.60

0.071

0.0020

0.45

0.0019

0.0010

0.055

Example 2

0.0015

0.43

1.34

0.110

0.0015

0.69

0.0016

0.0009 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com