Method for preparing non-oriented silicon steel with high magnetic induction

A technology of oriented silicon steel and a manufacturing method, which is applied in the direction of metal rolling, inorganic material magnetism, etc., can solve the problems of large hysteresis loss, long holding time and high soaking temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) Non-oriented silicon steel hot-rolled sheet, thickness 2.6mm, composition: Si 0.799%, Al 0.4282%, C 0.0016%, Mn 0.26%, P≤0.022%, S≤0.0033%, N≤0.0007%, Nb 0.0004 %, V 0.0016%, Ti 0.0009%; the rest are iron and unavoidable impurities.

[0037] (2) Cold rolling is performed on the hot-rolled sheet, and the reduction rate is 1-10%.

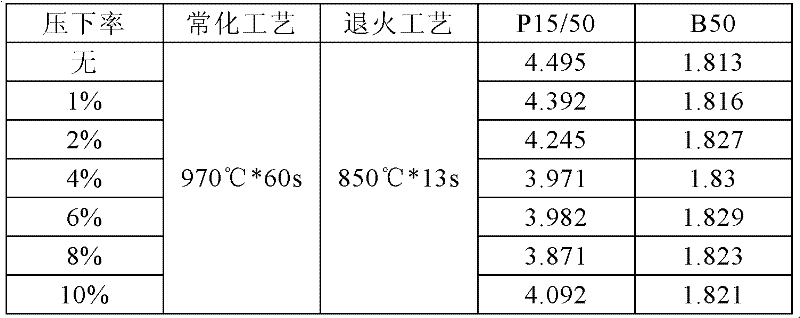

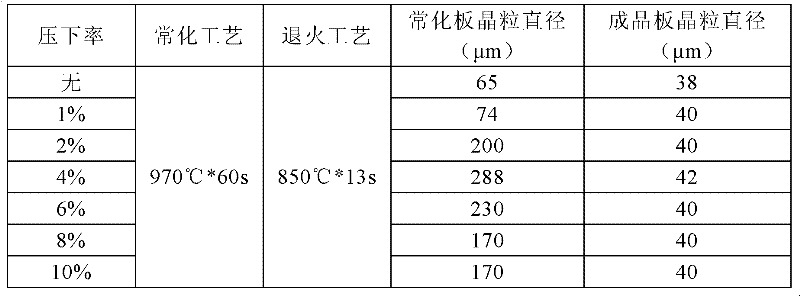

[0038] (3) Carry out normalization treatment, the normalization soaking temperature is 970°C, and the temperature is kept for 60s. After that, the normalized plate was pickled and then cold rolled to a thickness of 0.5 mm.

[0039] (4) Rapid heating annealing is carried out by using an electric heating annealing furnace in the laboratory. The heating rate is 250°C / s, the soaking temperature is 850°C, and the heat preservation time is 13s.

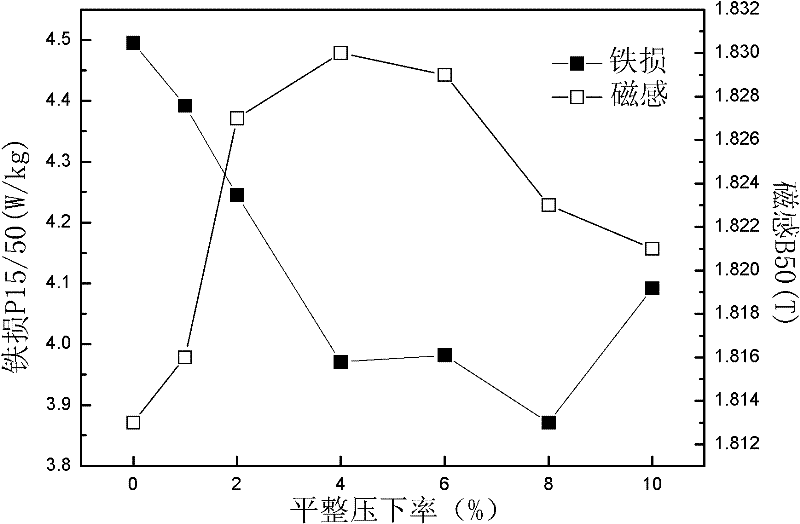

[0040]After the hot-rolled sheet is lightly reduced by 1-10%, the recrystallized structure of the normalized sheet becomes larger obviously, but the microstructure of the finished sheet has little dif...

Embodiment 2

[0047] (1) Non-oriented silicon steel hot-rolled sheet, thickness 2.6mm, composition: Si 1%, Al 0.2989%, C 0.0015%, Mn 0.297%, P 0.0572%, S 0.0027%, N 0.0009%, Nb 0.0005%, V 0.0015%, Ti 0.0011%; the rest is iron and unavoidable impurities.

[0048] (2) The hot-rolled sheet is cold-rolled at a reduction rate of 4%.

[0049] (3) Perform normalization treatment, the normalization soaking temperature is 950°C, and the temperature is kept for 60s. After that, the normalized plate was pickled and then cold rolled to a thickness of 0.5 mm.

[0050] (4) Use the electric heating annealing furnace in the laboratory to perform rapid heating annealing at different heating rates. The heating rate is 20°C / s, 150°C / s, 250°C / s, the soaking temperature is 960°C, and the heat preservation time is 13s.

[0051] The properties of the final annealed sheet are shown in Table 3.

[0052] Table 3. Magnetic properties of final annealed sheet of non-oriented silicon steel

[0053]

[0054] It c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com