Catalytic conversion method for improving product distribution

A catalytic conversion method and product technology, applied in the petroleum industry, dealing with hydrocarbon oil, etc., can solve problems such as poor selectivity, achieve the effects of reduced dry gas yield, reduced fragmentation tendency, and inhibition of overcracking and thermal cracking reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] This example illustrates the situation of increasing the isobutene content in liquefied gas and the olefin content in gasoline in a medium-sized variable-diameter riser reactor by adopting the method provided by the present invention and using a catalyst with a coarse particle size distribution.

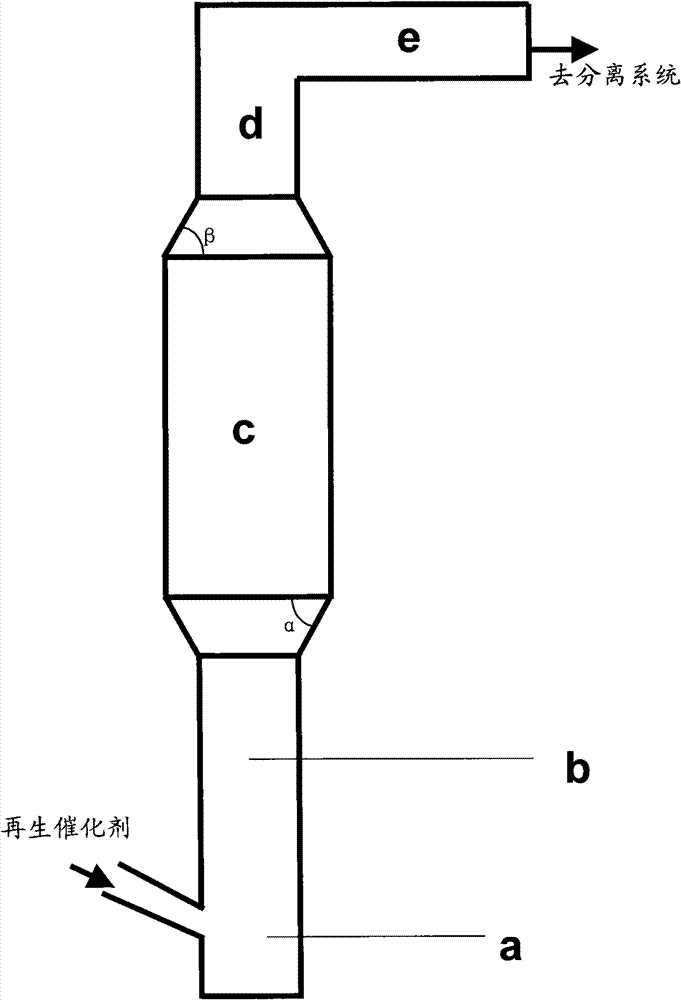

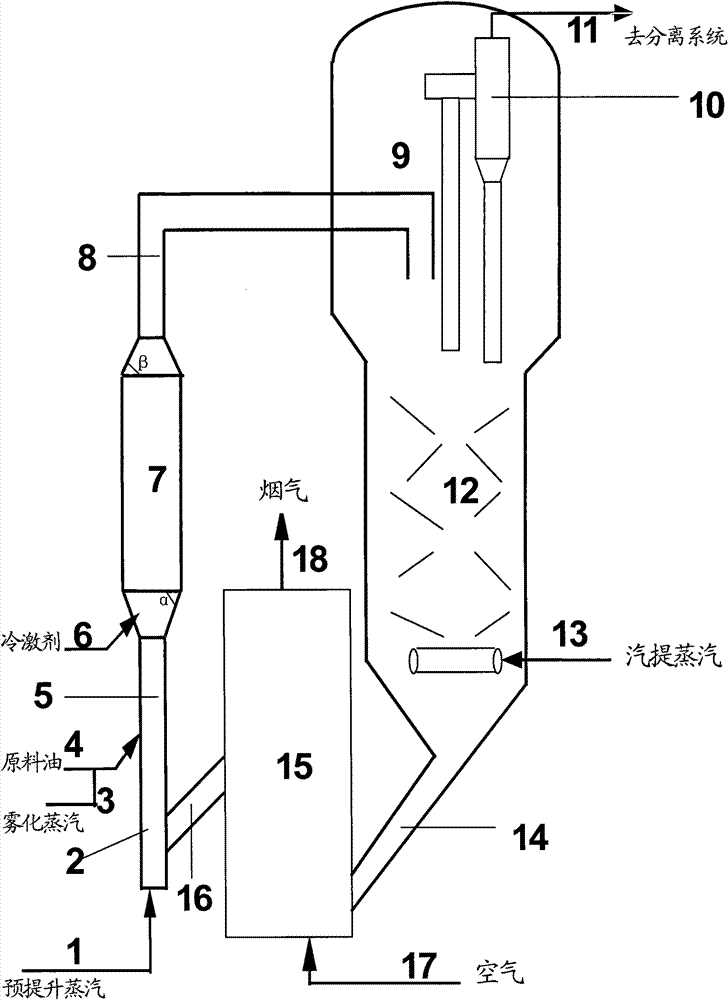

[0058] The total height of the pre-lift section, the first reaction zone, the second reaction zone and the outlet zone of the reactor is 15 meters, the diameter of the pre-lift section is 0.025 meters, and its height is 1.5 meters; the diameter of the first reaction zone is 0.025 meters, and its height It is 4 meters; the diameter of the second reaction zone is 0.1 meters, and its height is 6.5 meters; the diameter of the outlet zone is 0.025 meters, and its height is 3 meters; is 45°; the base angle of the isosceles trapezoid in the longitudinal section of the junction of the second reaction zone and the outlet zone is 60°.

[0059] The preheated raw material oil listed in Ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com