Positioning device for workbench

A positioning device and workbench technology, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of frequent alarms in the pneumatic detection of the workbench, and achieve the effect of simple structure, high degree of combination, and simple movement mode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in combination with principle diagrams and specific operation examples.

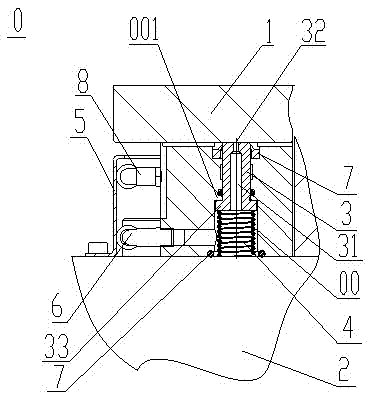

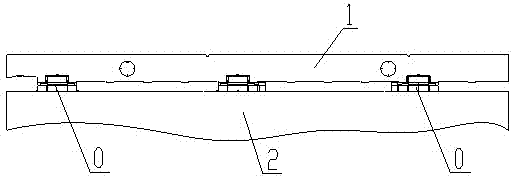

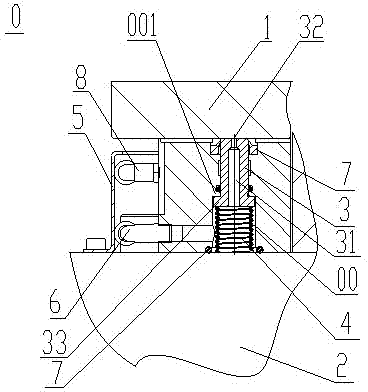

[0021] like figure 1 As shown, the workbench positioning device of the present invention includes several positioning blocks 0 arranged between the workbench part 1 and the workbench base 2, the positioning block 0 can also be installed on the intermediate body, and the positioning block 0 is provided with a through hole cavity 00, fill a piston 3 in the through hole cavity 00, the lower end of the piston 3 is movably supported up and down on the surface of the workbench base 2 through an elastic component 4, and the elastic component 4 is specifically a spring. A gas detection through hole (not marked in the figure) is set horizontally on the inner side of the through hole chamber 00, the gas detection through hole is externally connected to the first gas pipe joint 6, a gas detection channel 31 is opened in the piston 3, and a gas detection c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com