Hydrodewaxing catalyst, preparation method and application thereof

A hydrogenation dewaxing and catalyst technology, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of paraffin selectivity reduction, molecular sieve skeleton collapse, catalyst reduction, etc., and achieve low cracking capacity , reduce side reactions, high catalytic activity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

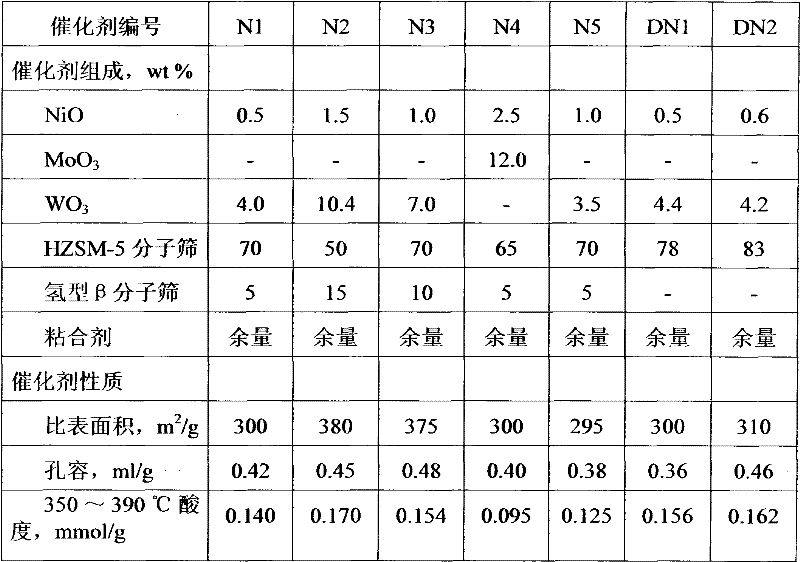

Image

Examples

Embodiment 1

[0030] Will be made of small hole alumina (specific surface 238m 2 g -1 , pore volume 0.48mL·g -1 ) made of binder added to HZSM-5 molecular sieve (SiO 2 / Al 2 o 3 Molar ratio 38) and hydrogen type β molecular sieve (Si / Al molar ratio 26, specific surface area is 420m 2 / g, with a relative crystallinity of 90%), mixed uniformly, extruded, dried at 130°C for 4 hours, and calcined at 580°C for 4 hours to obtain a carrier.

[0031] The above-mentioned carrier is added to an aqueous magnesium nitrate solution with a magnesium oxide content of 5 wt% and impregnated by equal volume for 5 hours. After filtering, the obtained solid phase is dried at 120° C. for 4 hours to obtain a magnesium-modified carrier.

[0032] Add cyclohexane to dimethyl silicone oil to obtain a silicone oil-organic mixed solution with a silicon oxide weight concentration of 15 wt%, and then add the magnesium-modified carrier to the above-mentioned silicone oil-organic mixed solution to immerse in an equal v...

Embodiment 2

[0035] Will be made of small hole alumina (specific surface 238m 2 g -1 , pore volume 0.48mL·g -1 ) was added to the mixture of HSM-5 molecular sieve and hydrogen-type β molecular sieve (same as Example 1), kneaded evenly, extruded, then dried at 130°C for 4 hours, and roasted at 580°C for 4 hours. Get the carrier.

[0036] The above-mentioned carrier is added to an aqueous solution with a calcium oxide content of 6wt% calcium nitrate and impregnated at a volume ratio of 1:1.5. The impregnation time is 4 hours. After filtering, the obtained solid phase is dried at 100°C for 5 hours to obtain calcium-modified carrier.

[0037] Add solvent gasoline to ethyl silicone oil to obtain a silicone oil-organic mixed solution with a silicon oxide weight concentration of 20 wt%, and then add the calcium-modified carrier to the above-mentioned silicone oil-organic mixed solution for immersion at a volume ratio of 1:1.5, and the immersion time for 3 hours. After filtration, it was drie...

Embodiment 3

[0040] The preparation of the carrier is the same as in Example 1.

[0041] The above-mentioned support was added to an aqueous zinc nitrate solution with a zinc oxide weight content of 6 wt% and impregnated by equal volume for 5 hours. After filtering, the obtained solid phase was dried at 120° C. for 4 hours to obtain a zinc-modified support.

[0042] Add xylene to phenylmethyl silicone oil to obtain a silicone oil-organic mixed solution with a silicon oxide weight concentration of 18%, and then add the zinc-modified carrier to the above-mentioned silicone oil-organic mixed solution for impregnation at a volume ratio of 1:2. The time is 3 hours. After filtration, it was dried at 100° C. for 4 hours and calcined at 580° C. for 4 hours to obtain a zinc-silicon-modified carrier S3, wherein the zinc oxide weight content was 2.0%, and the silicon oxide surface coating content was 5.0 wt%.

[0043] The obtained carrier S3 was immersed in an aqueous solution containing nickel and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com