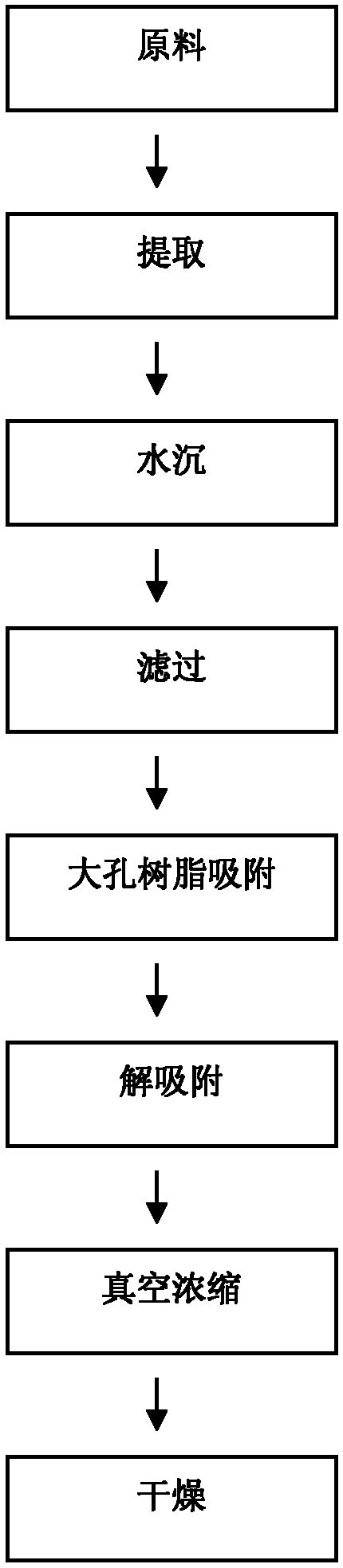

Preparation method of olive leaf extract

The technology of olive leaf extract and olive dried leaf is applied in the field of preparation of olive leaf extract, can solve the problems of high cost, complicated extraction steps, low content of oleuropein, prevents purification and regeneration, and is suitable for scale Production, no environmental pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] Before utilizing the preparation method of the olive leaf extract to produce the olive leaf extract rich in oleuropein, the olive leaves are usually selected and pretreated.

[0043] Generally, affected by the growth cycle, the content of oleuropein in olive leaves picked in April and November is the lowest. Therefore, according to the present invention, in order not to greatly affect the content of oleuropein in the final extract, the The olive leaves are not collected during these two months. In addition, at other times of the year, although the content of oleuropein in olive leaves will fluctuate due to the influence of the growth cycle, it does not have much impact on the minimum content of oleuropein in the obtained olive leaf extract. In order to obtain higher content of oleuropein in the olive leaf extract, the olive leaves can also be collected in February or May according to the suggestion in Chinese patent CN101003557.

[0044] The fresh olive leaves collecte...

Embodiment 1

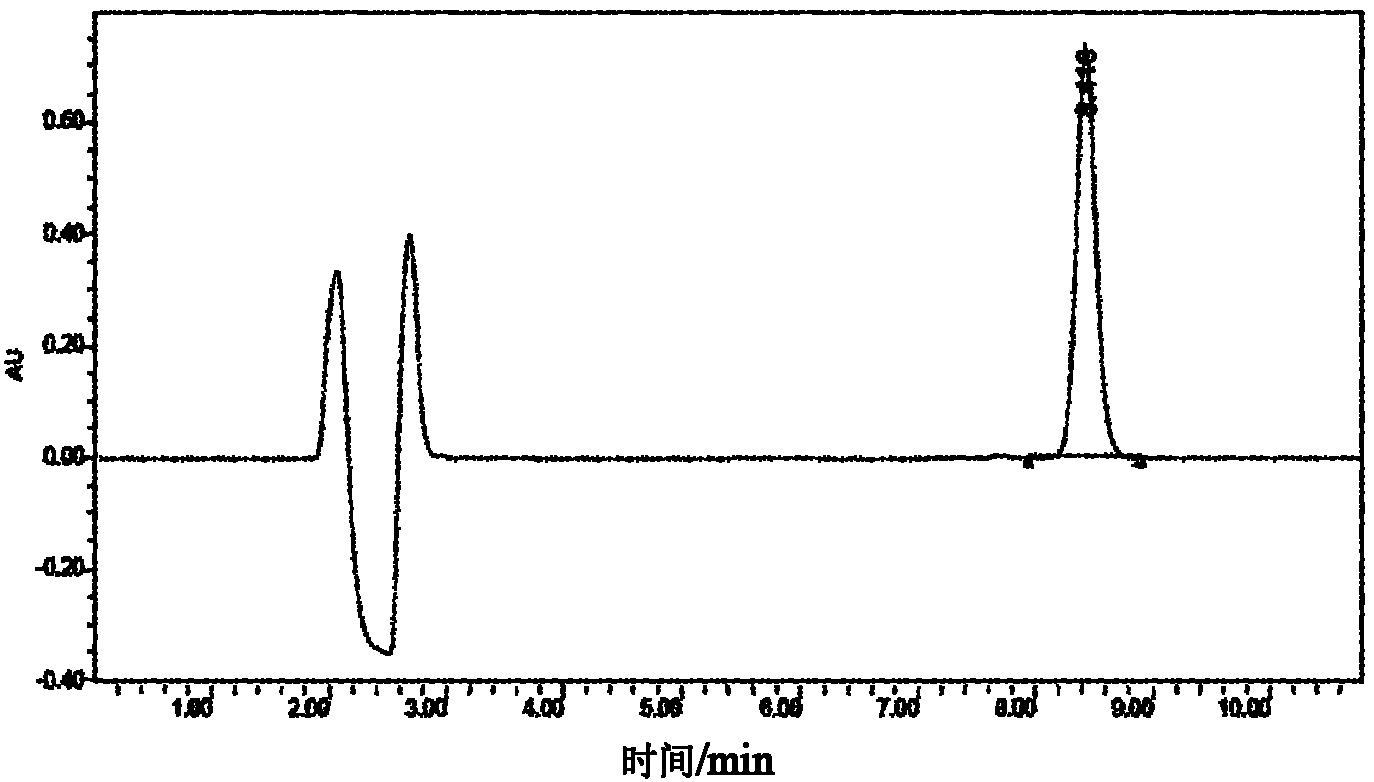

[0107] 200kg of dried olive leaves, after testing, the moisture content is less than 6%, and the oleuropein content is greater than 5%. Crumble olive leaves into coarse powder, heat and reflux extract twice with 1400L alcoholic 75% ethanol aqueous solution, each time for 4 hours, concentrate the extract after recovering ethanol, add 2000L water to the concentrated solution, add diatomaceous earth as an auxiliary material at the same time, mix Evenly, let it stand for 12 hours, press filter, put the filtrate on a 400kg D101 macroporous resin column, flow rate 0.5BV / h, desorb with an ethanol aqueous solution with an alcohol content of 70%, and concentrate in vacuo after recovering ethanol from the desorption solution, concentrate to 10°Bé, spray dry, Obtain 10.3kg of olive leaf extract, the yield is 5.15%, and the content of oleuropein is 61%. In this embodiment, the HPLC collection of illustrative plates of detecting the oleuropein content of olive leaf extract is as follows ...

Embodiment 2

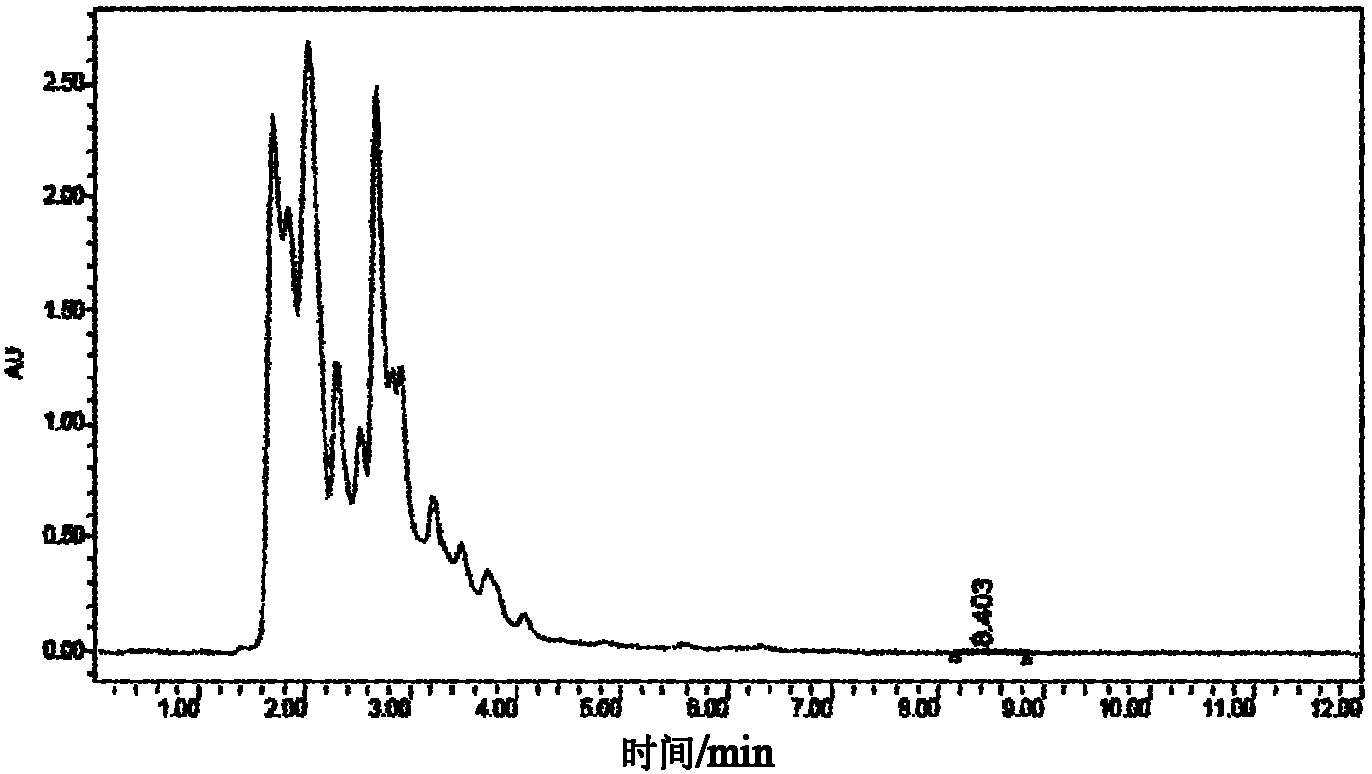

[0109] 200kg of dried olive leaves, after testing, the moisture content is less than 6%, and the oleuropein content is greater than 5%. Crush part of the olive leaves into coarse powder, do not crush a small amount, moisten it with an appropriate amount of 70% ethanol aqueous solution to make it fully expand, pack it into a cylinder, flatten it evenly, open the piston of the percolate outlet, and add alcohol from the top 70% ethanol aqueous solution until the percolation liquid flows out from the outlet, and the solvent immerses the surface for several centimeters. After soaking for 24 hours, start percolation with 2000L of 70% ethanol at a flow rate of 100L / h, combine the percolation solution, recover ethanol from the percolation solution, add 1600L of water to the concentrated solution, add diatomaceous earth as an auxiliary material, mix well, and let it stand for 8 hours. Pressure filtration, 400kg D101 macroporous resin column on the filtrate, flow rate 0.5BV / h, desorptio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com