Method for manufacturing high-temperature speckles

A speckle and high temperature technology, which is applied in the direction of photo-plate-making process coating equipment, photo-plate-making process exposure device, measuring device, etc., can solve the problem of high cost, and achieve the effect of low production cost, simple process and simple production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

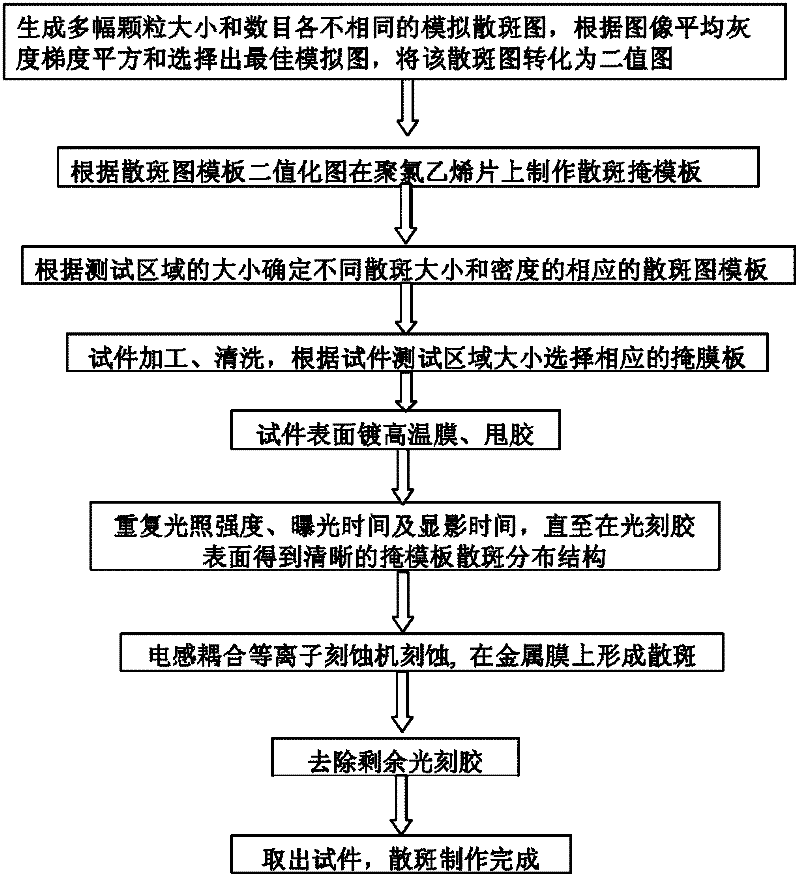

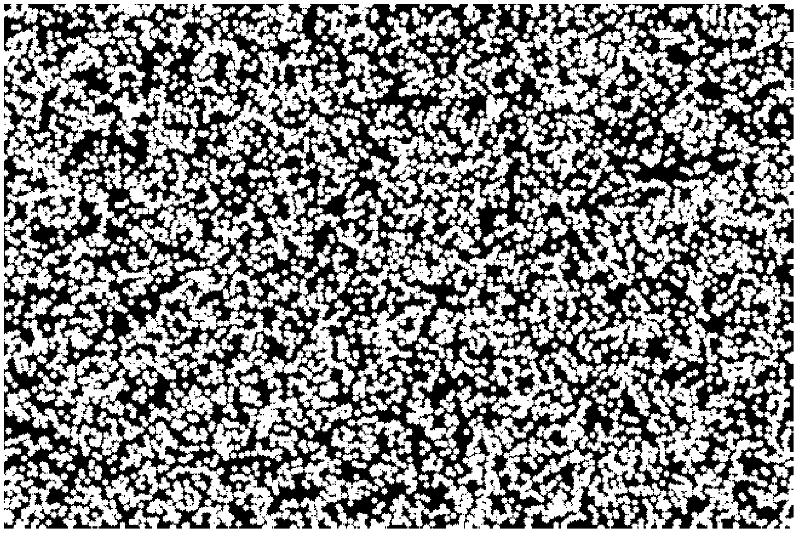

[0022] Use Matlab software to generate multiple simulated speckle patterns with different particle sizes and numbers. The simulated speckle pattern is composed of a number of randomly distributed Gaussian spots, and its gray distribution can be expressed by the following formula:

[0023] I ( r ) = Σ k = 1 s I k 0 exp ( - ( r - r k ) 2 R 2 ) - - - ( 1 )

[0024] Among them, s is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com