Method for epoxidizing olefinic hydrocarbon

A technology of epoxidation reaction and olefin, which is applied in the direction of organic chemistry, can solve the problems of low selectivity and incomplete conversion of propylene oxide, and achieve the effects of reducing equipment cost, overcoming low selectivity and shortening the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

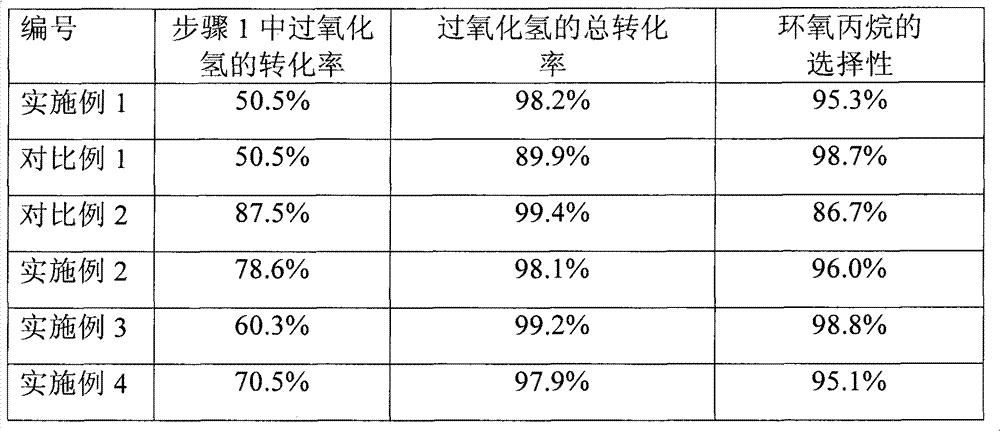

Embodiment 1

[0037] (1) The titanium-silicon molecular sieve powder catalyst was loaded in a moving bed reactor (purchased from Chengdu Xindu Yongtong Machinery Factory), and the concentration of the catalyst in the material was 5% by weight. A first mixed material containing propylene, methanol and hydrogen peroxide is introduced into the moving bed reactor, wherein, in the first mixed material, the molar ratio of methanol, propylene and hydrogen peroxide is 10:4:1. The conditions of the reaction include: the temperature is 35° C., the pressure is 1 MPa, the time is 8 hours, the pH=5 of the first mixture material is adjusted with ammonia water, the amount of hydrogen peroxide in the reaction mixture is detected by the iodometric method, and Calculate the conversion rate of hydrogen peroxide according to the calculation formula (1) shown above, and the results are shown in Table 1. The amount of propylene oxide generated in the step (1) is detected by the chromatographic internal standard ...

Embodiment 2

[0044] (1) The titanium-silicon molecular sieve powder catalyst was loaded in a moving bed reactor (purchased from Chengdu Xindu Yongtong Machinery Factory), and the concentration of the catalyst in the material was 5% by weight. The first mixed material containing propylene, methanol and hydrogen peroxide is introduced into the moving bed reactor, wherein, in the first mixed material, the molar ratio of methanol, propylene and hydrogen peroxide is 4:2:1. The conditions of the reaction include: the reaction temperature is 75° C., the reaction pressure is 4 MPa, the time is 2 hours, the pH=7 of the first mixture material is adjusted with ammonia water, and the amount of hydrogen peroxide in the reaction mixture is detected by iodometric method, And calculate the conversion ratio of hydrogen peroxide according to the calculation formula (1) shown above, the results are as shown in table 1. And detect the amount of propylene oxide generated in the step (1) by the chromatographic ...

Embodiment 3

[0047] (1) The titanium-silicon molecular sieve powder catalyst was loaded in a moving bed reactor (purchased from Chengdu Xindu Yongtong Machinery Factory), and the concentration of the catalyst in the material was 5% by weight. A first mixed feed containing propylene, methanol, and hydrogen peroxide is introduced into the moving bed reactor, wherein, in the first mixed feed, the molar ratio of methanol, propylene, and hydrogen peroxide is 6:0.5:1. The conditions of the reaction include: the reaction temperature is 50° C., the reaction pressure is 3 MPa, the time is 5 hours, the pH=6 of the first mixture material is adjusted with ammonia water, and the amount of hydrogen peroxide in the reaction mixture is detected by iodometric method, And calculate the conversion rate of propane hydroperoxide according to the calculation formula (1) shown above, the results are as shown in table 1. And detect the amount of propylene oxide generated in the step (1) by the chromatographic int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com