Plate glass packing box, as well as packing method, unpacking method and unpacking device for plate glass packing box

A packaging method and glass plate technology, which is applied in the directions of transportation and packaging, packaging, and the type of packaged items, can solve the problems of operability, strength, handling costs, small number of sheets loaded, and low handling efficiency, etc., to achieve efficient take-out operations, Safe positioning work and improved operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

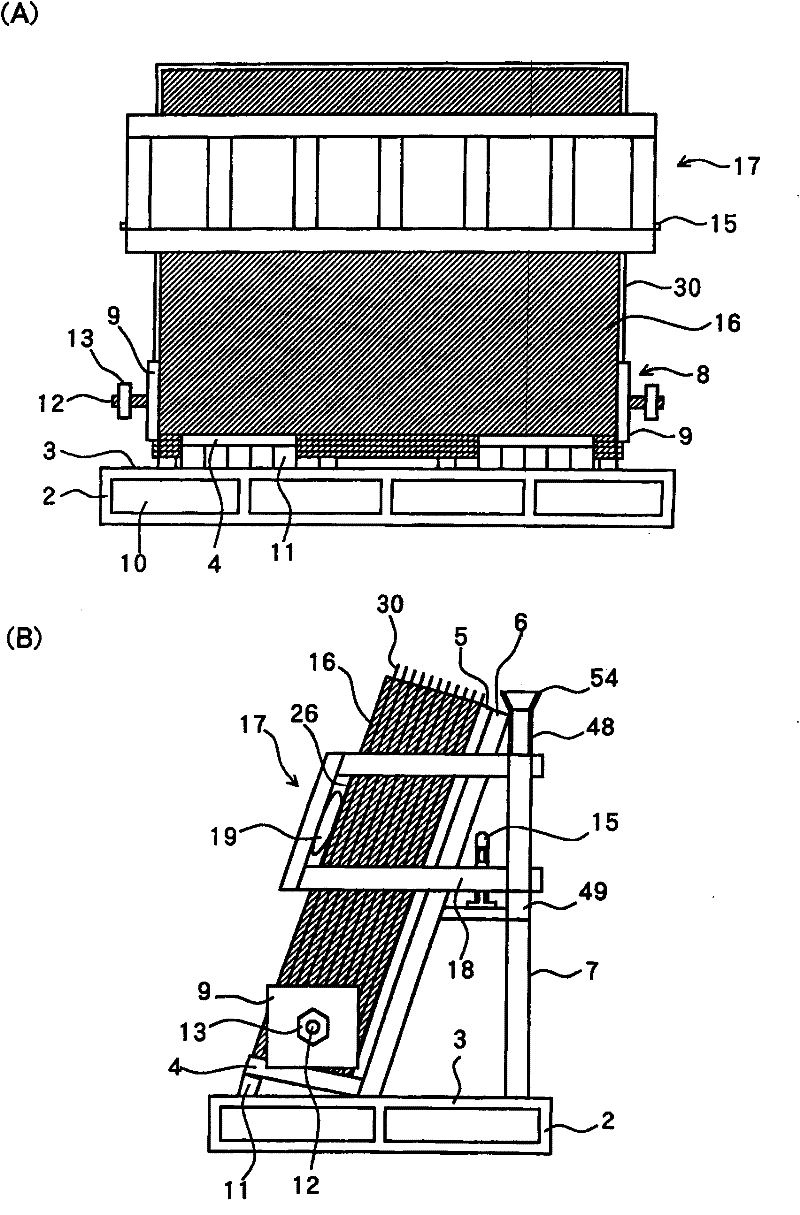

[0054] figure 1 It is a schematic diagram which shows the state before mounting a glass plate in the glass plate packing box of this invention, (A) is a front view, (B) is a side view.

[0055] On the mounting surface 3 that is the upper surface of the pedestal 2 serving as a base, a bottom receiving plate 4 on which a glass plate is placed is provided obliquely. A plurality of vertical pieces 6 (pillar-shaped) are provided on the mounting surface 3 in a manner of 90° to 100°, particularly preferably about 95°, with respect to the bottom receiving plate 4, and the back receiving plate 5 on the surface of the glass plate is adjacent to the mounting surface 3. On the vertical piece 6. Buffers (not shown) such as rubber or hard foaming resin are provided on the bottom receiving plate 4 and the back receiving plate 5 in order to prevent damage caused by contact with the glass plate when the glass plate is placed. At this time, if the width of the bottom receiving plate 4 is made...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com