Method for forging alloy steel ingot with smaller diameter and larger height-diameter ratio into wider flat billet

An alloy steel, smaller technology, applied in metal processing equipment and other directions, to achieve the effect of improving yield, improving quality and reducing material loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The electroslag ingot Ф480mm is forged into a wide slab of 620mm×150mm.

[0025] Its forging steps are:

[0026] 1. After the steel ingot 3 is thoroughly burned, the steel ingot 3 is directly placed horizontally on the platform 4 by using a trackless car or a crane for feeding;

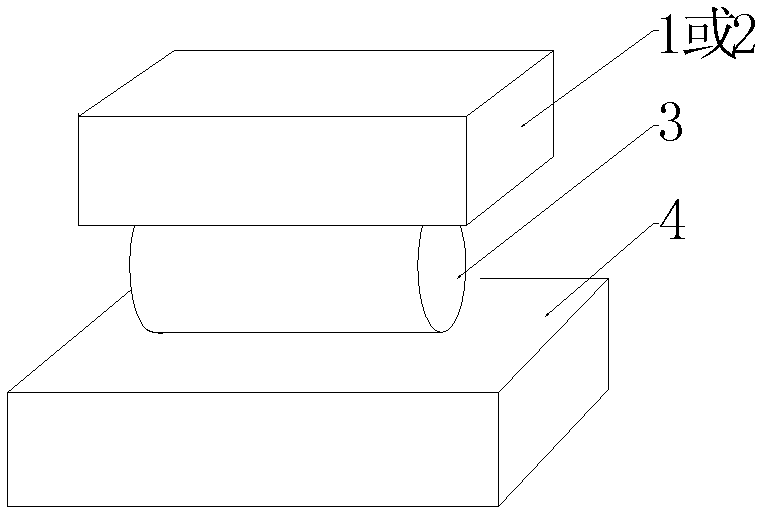

[0027] 2. Use the upper wide flat anvil 1 to carry out heavy pressure on the steel ingot 3 placed horizontally on the platform 4 (such as figure 1 ), with a reduction of 200mm to 220mm, forged into a blank 7;

[0028] 3. After leveling, measure the width of the blank 7 to reach 650mm-680mm, fully achieving the widening effect;

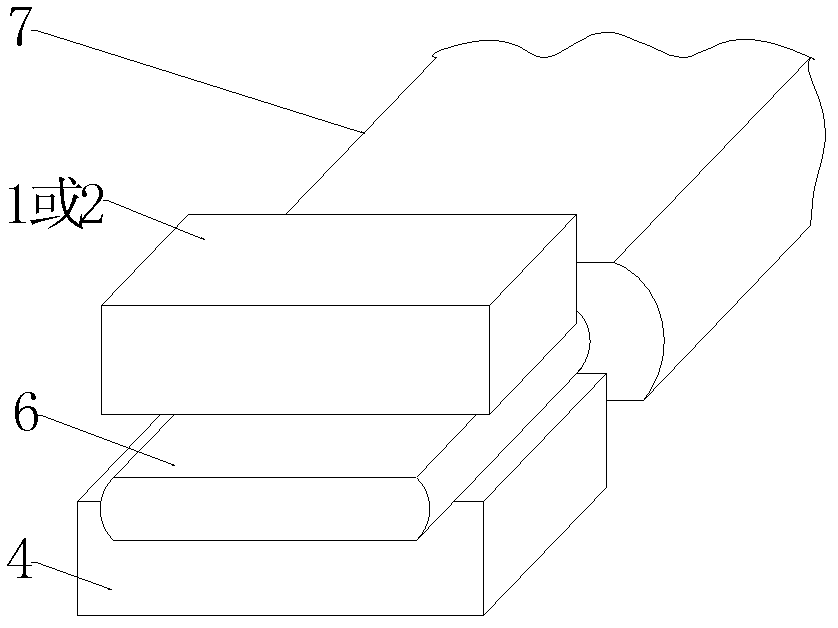

[0029] 4. The widened blank 7 directly presses the flat jaw 6 at the end of the bottom pad (such as image 3 ), then return to the furnace and burn again;

[0030] 5. The billet 7 is refired for 1.5h to 2h and released from the furnace, and is forged into a 620mm×150mm slab in one fire; the surface of the slab has no damage.

Embodiment 2

[0032] The Ф508mm consumable ingot has a diameter of Ф480mm after turning, and is forged into a wide slab of 620mm×150mm.

[0033] Its forging steps are:

[0034] 1. After the steel ingot 3 is thoroughly burned, the steel ingot 3 is directly placed horizontally on the platform 4 by using a trackless car or a crane for feeding;

[0035] 2. Use the upper flat anvil 2 to carry out heavy pressure on the steel ingot 3 placed horizontally on the platform 4 (such as figure 1 ), the reduction is 80mm~120mm;

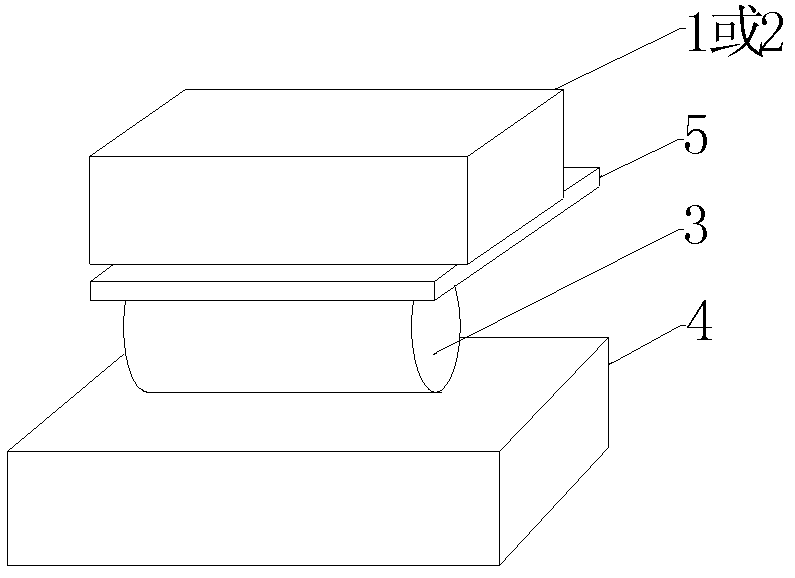

[0036] 3. Place the upsetting plate 5 between the steel ingot 3 and the upper flat anvil 2 to repress the steel ingot 3 (such as figure 2 ), control the reduction of 80mm ~ 120mm, forging into blank 7;

[0037] 4. After leveling, measure the width of the blank 7 to reach 650mm-680mm, fully achieving the widening effect;

[0038] 5. The widened blank 7 directly presses the flat jaw 6 at the end of the bottom pad (such as image 3 ), then return to the furnace and burn again;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com