Three-roller grinding mill

A technology of three-roller grinding machine and adjusting roller, which is applied in the field of grinding machinery, can solve the problems of affecting the effect and efficiency of the grinding machine, shortening the life of the machine, and easy dripping of materials, so as to achieve reasonable force, increase life, and not easy to drip Effect

Inactive Publication Date: 2012-05-09

苏州冰心文化用品有限公司

View PDF7 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

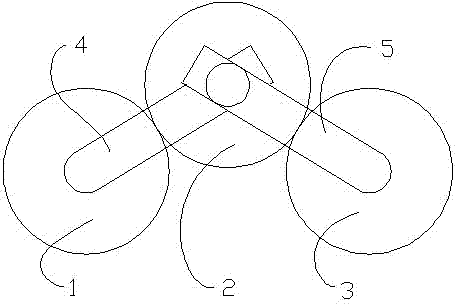

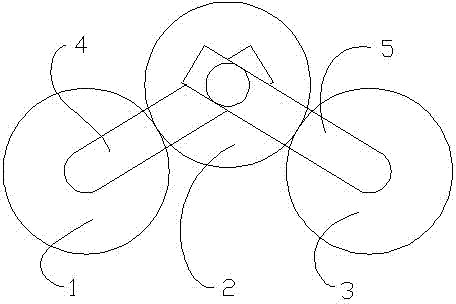

[0002] As the most effective grinding machine for high-viscosity materials, the three-roller mill is widely used in pigments, plastics, paints, etc. The three-roller mill has three rollers installed on an iron frame to squeeze each other and friction at different speeds to achieve the grinding effect. Usually, the three rollers of the three-roller grinder are on the same horizontal plane. In this way, when the three-roller grinder grinds raw materials, its force is pressed along the closest point of the three rollers to the axis. The three rollers are on the same horizontal plane, and the force line between them is on the same horizontal plane and perpendicular to the gravity of each roller, so that the total force at the connection of each roller increases and the wear increases, which shortens the life of the machine

Moreover, when the middle roller is feeding, because the grinding point between the middle roller and the rollers at both ends is at the two ends of the horizontal diameter of the roller, the material will be attached to the middle roller and rotate half a circle, the stroke is too long, and the corner is too large. Large, the material is very easy to drip during this process, which affects the effect and efficiency of the grinder

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

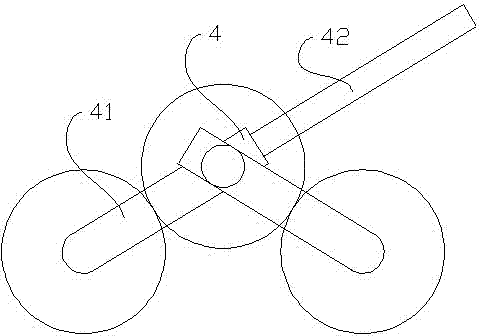

The invention provides a three-roller grinding mill, which belongs to the technical field of grinding machinery. The three-roller grinding mill comprises a fixed roller, an adjusting roller, a passive adjusting roller, an active connecting mechanism and a passive connecting mechanism, and is characterized in that: one end of the active connecting mechanism is hinged with the fixed roller, the other end of the active connecting mechanism is connected with the adjusting roller, and the active connecting mechanism drives the adjusting roller to rotate around the axle center of the fixed roller; two ends of the passive connecting mechanism are respectively hinged with the adjusting roller and the passive adjusting roller. According to the invention, the three-roller grinding mill has a more stable structure, and since a discharging position of the adjusting roller is attached onto a top, ground materials do not easily fall onto a feeding position again, thereby improving efficiency of the grinding mill, reducing shaking and friction of the grinding mill and prolonging the service life of the grinding mill.

Description

Technical field [0001] The invention relates to the technical field of grinding machinery, in particular to a three-roll grinder whose middle roll can be turned over. Background technique [0002] As the most effective grinding machine for high-viscosity materials, the three-roll grinder has a wide range of applications in pigments, plastics, paints, etc. The three-roll grinder has three rollers installed on an iron frame to squeeze each other And the friction of different speeds to achieve the grinding effect, usually the three rollers of the three-roll grinder are on the same horizontal surface, so when the three-roll grinder is grinding the raw material, its force is pressed along the closest point of the three rollers to the axis. The three rollers are on the same horizontal plane, and the lines of force between them are on the same horizontal plane and vertical to the gravity of each roller. In this way, the total force that connects the rollers increases the wear and tear...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B02C4/02B02C4/32

Inventor 李小福

Owner 苏州冰心文化用品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com