Loudspeaker and manufacturing method thereof

A loudspeaker and passive radiator technology, applied in the direction of sensors, stereo devices, sensor components, etc., can solve the problems of reducing the thickness of the speaker, unsatisfactory sound effect, and difficulty in satisfying modern people, so as to avoid surface assembly problems and excellent sound quality , powerful effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

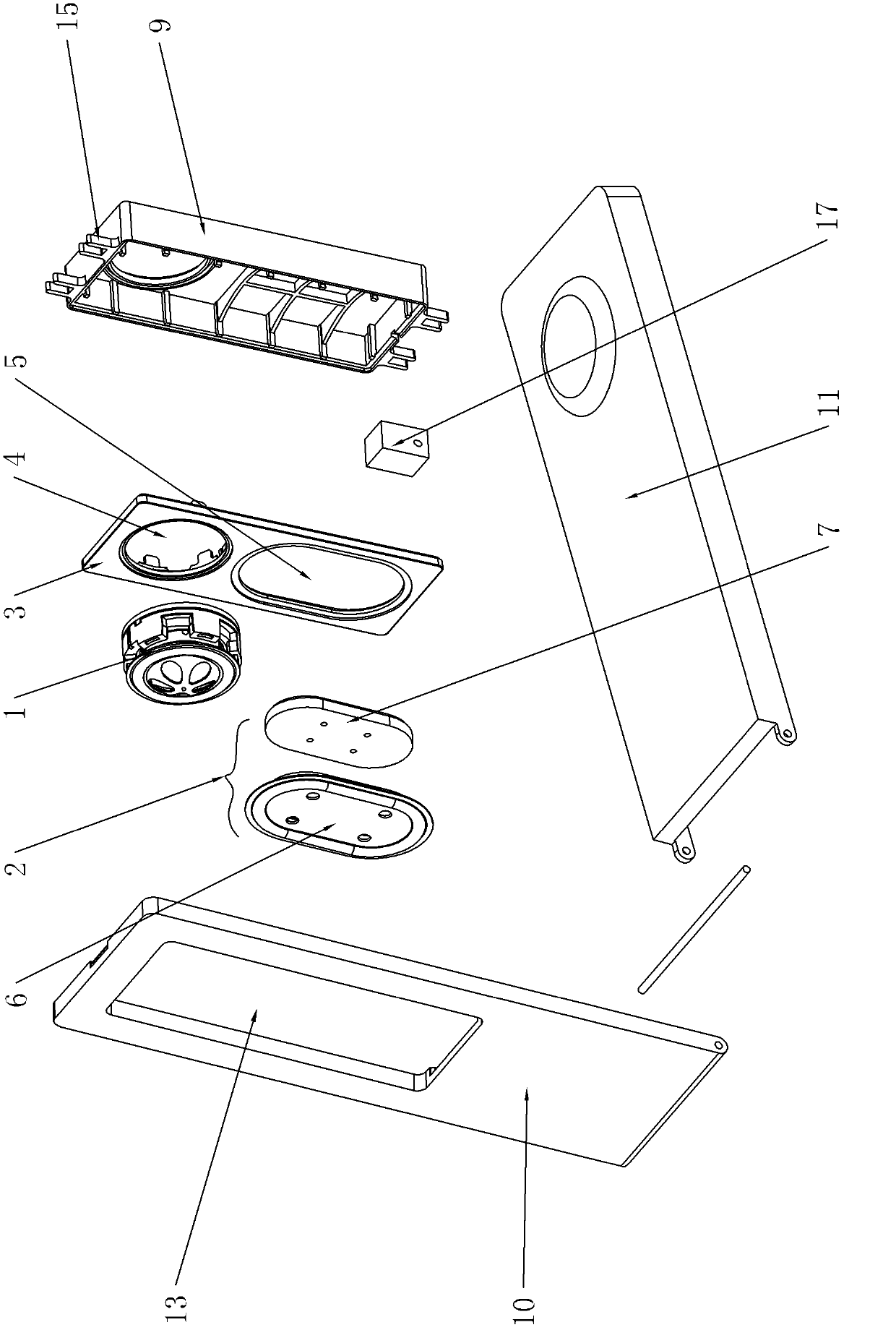

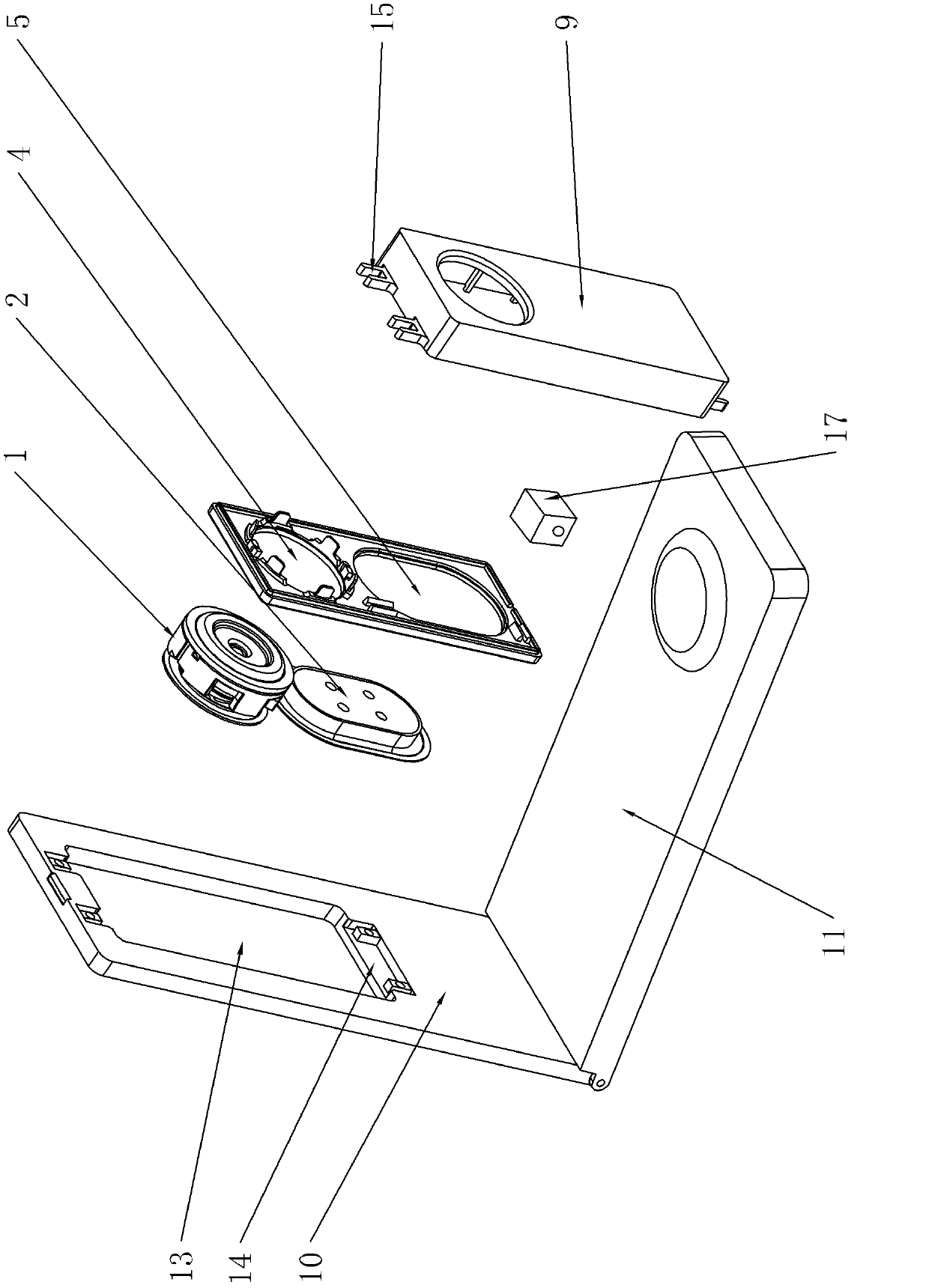

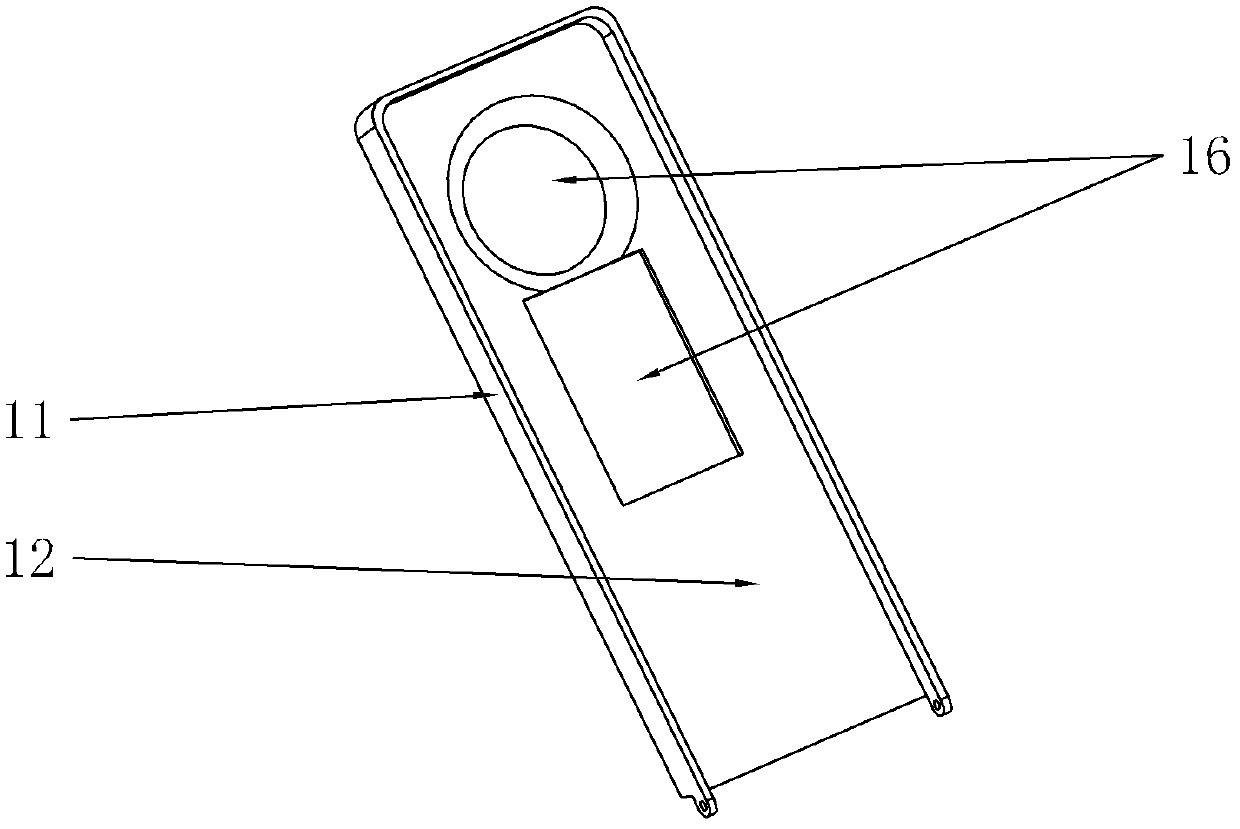

[0040] like Figures 1 to 4 As shown, the speaker of the present invention includes a speaker module, and the speaker module includes a speaker 1, a passive radiator 2 and a speaker panel 3, wherein:

[0041] The above-mentioned speaker panel 3 is provided with a mounting hole 4, and the above-mentioned speaker 1 is arranged at the installation hole 4 and is integrated with the speaker panel 3 through insert injection molding; the speaker panel 3 on the side of the above-mentioned mounting hole 4 is provided with a secondary installation hole 5 The above-mentioned passive radiator 2 is arranged in the auxiliary installation hole 5 and is integrated with the speaker panel 3 through insert injection molding; the above-mentioned speaker 1 includes a diaphragm, a hanging edge and an outer frame, and the above-mentioned diaphragm, hanging edge and outer frame The edge basin frame is integrally injected into a vibrating drum paper; the above-mentioned diaphragm and the speaker panel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com