Stator structure of electric compressor

An electric compressor, stator structure technology, applied in electric components, magnetic circuit shape/style/structure, electrical components, etc., can solve the problem that the cross-section of the flow channel cannot be made larger, the shaft cannot be too thick, and the inner and outer circle structures are enlarged, etc. problems, to achieve the effect of improving the structural manufacturability, reducing the cost of the whole machine, and improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

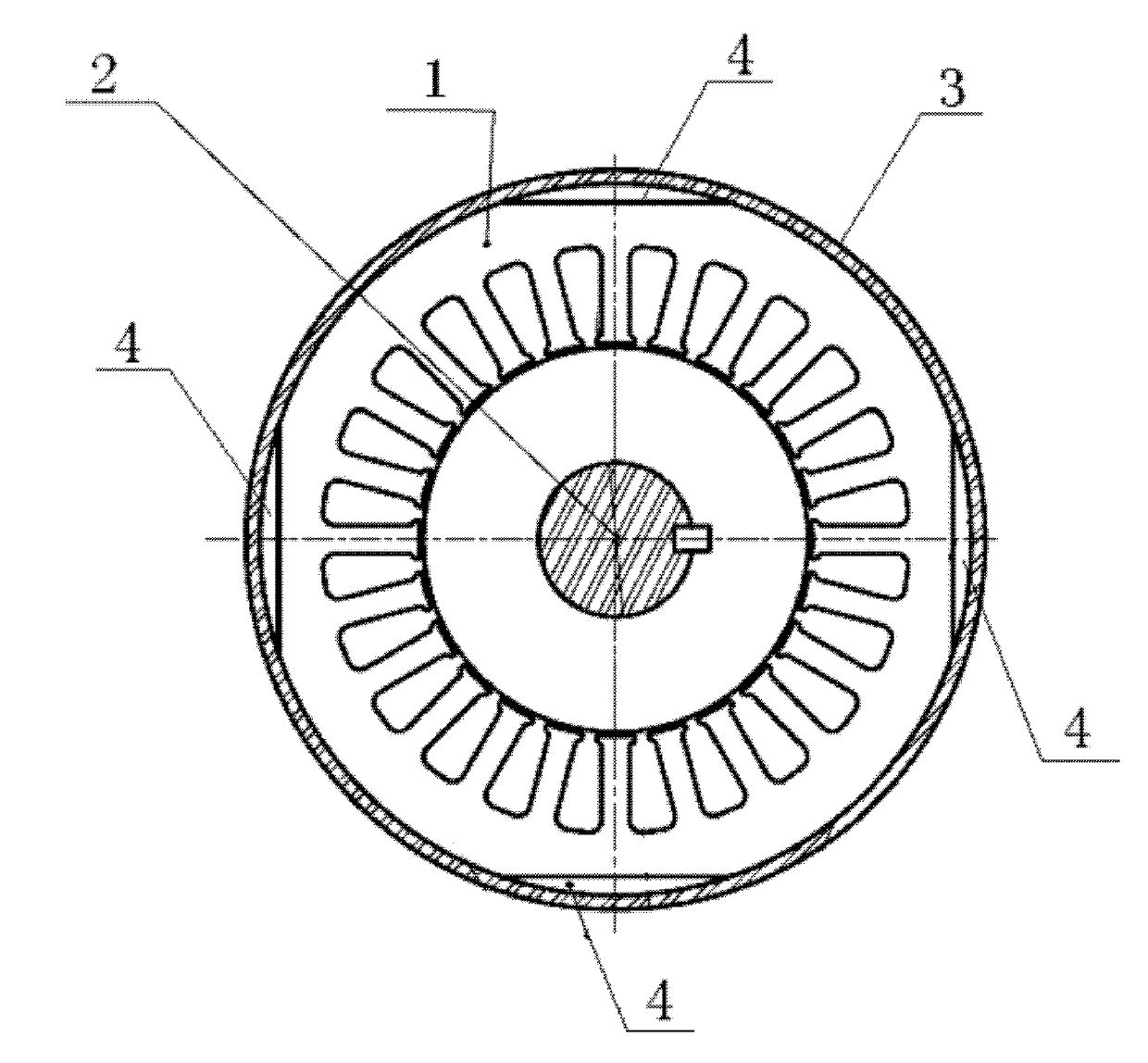

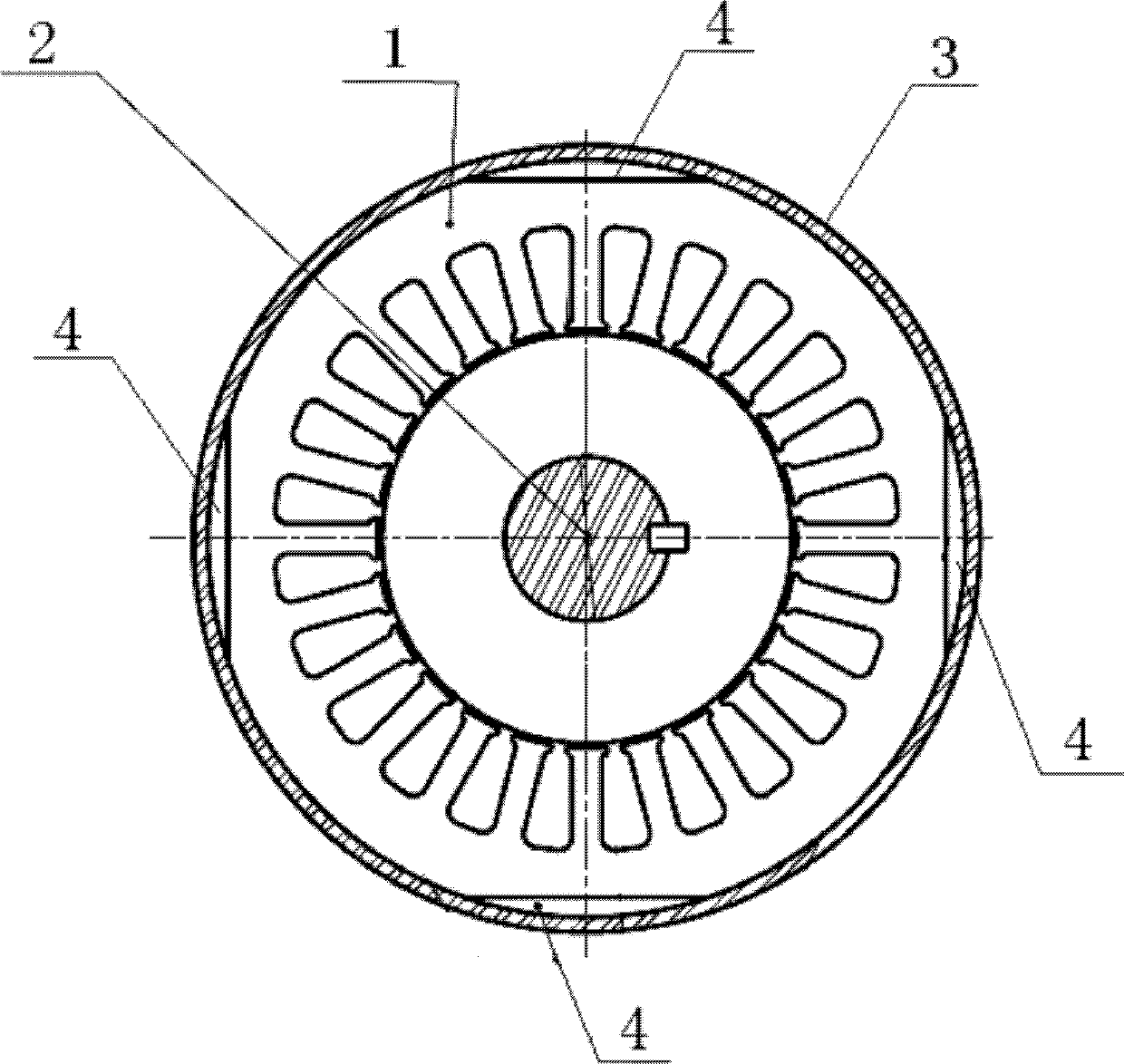

[0015] like figure 1 As shown, the present invention is a motor stator core 1; a solid motor shaft 2; a casing inner ring 3; the cross-sectional shape of the motor stator iron core 1 is a square circle, and the cross-section of the casing inner ring 3 is a circular cross-section.

[0016] The gap between the square side of the motor stator core 1 and the inner ring 3 of the casing is the refrigerant flow channel 4, and the size of the gap is determined according to different types of compressors. The stator core 1 of the motor is made of silicon steel sheets of 0.35-0.5 mm in size and laminated after cold stamping, and its groove shape is a pear-shaped groove.

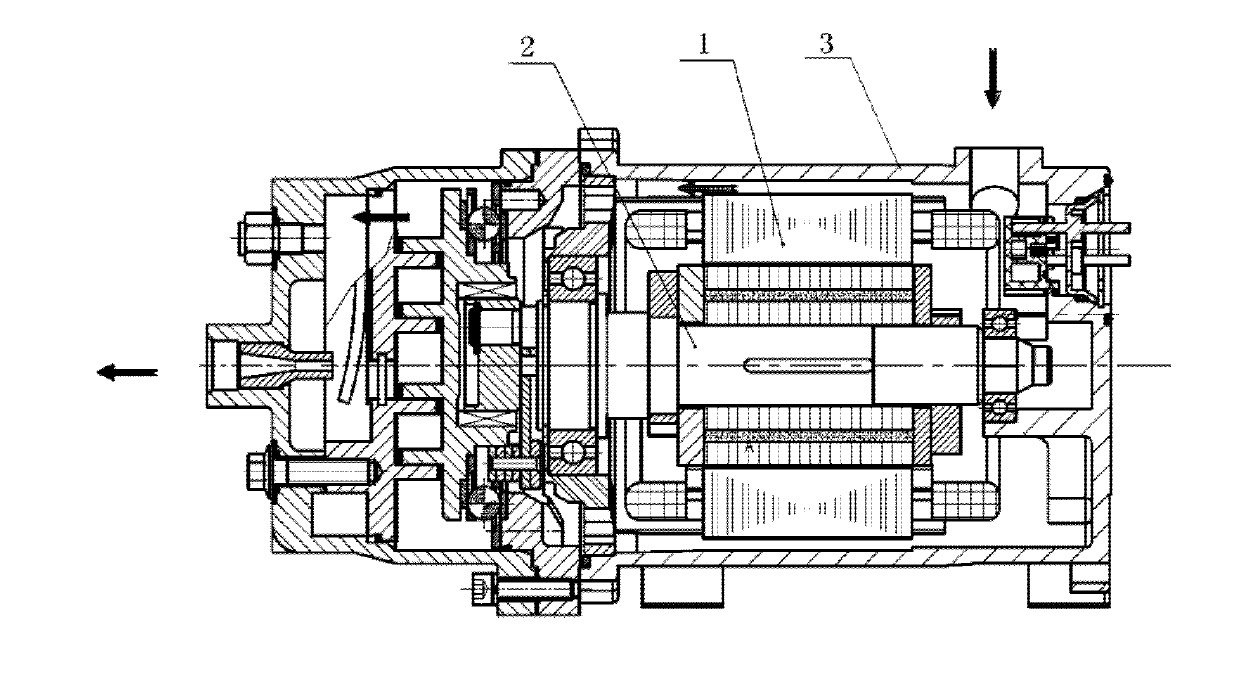

[0017] like figure 2 As shown, the direction of the arrow in the figure is the flow direction of the refrigerant. The present invention uses a square circular section motor stator core 1 structure on the electric compressor to generate a flow path for the compressor refrigerant to flow, thereby increasing the cross-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com