Single-phase traction transformer for high-speed electrified railway in AT (auto-transformer) power supply way

A technology for electrified railways and traction transformers, applied to transformers, fixed transformers, circuits, etc., can solve the problems of complex structure, unsatisfactory and high cost of transformers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

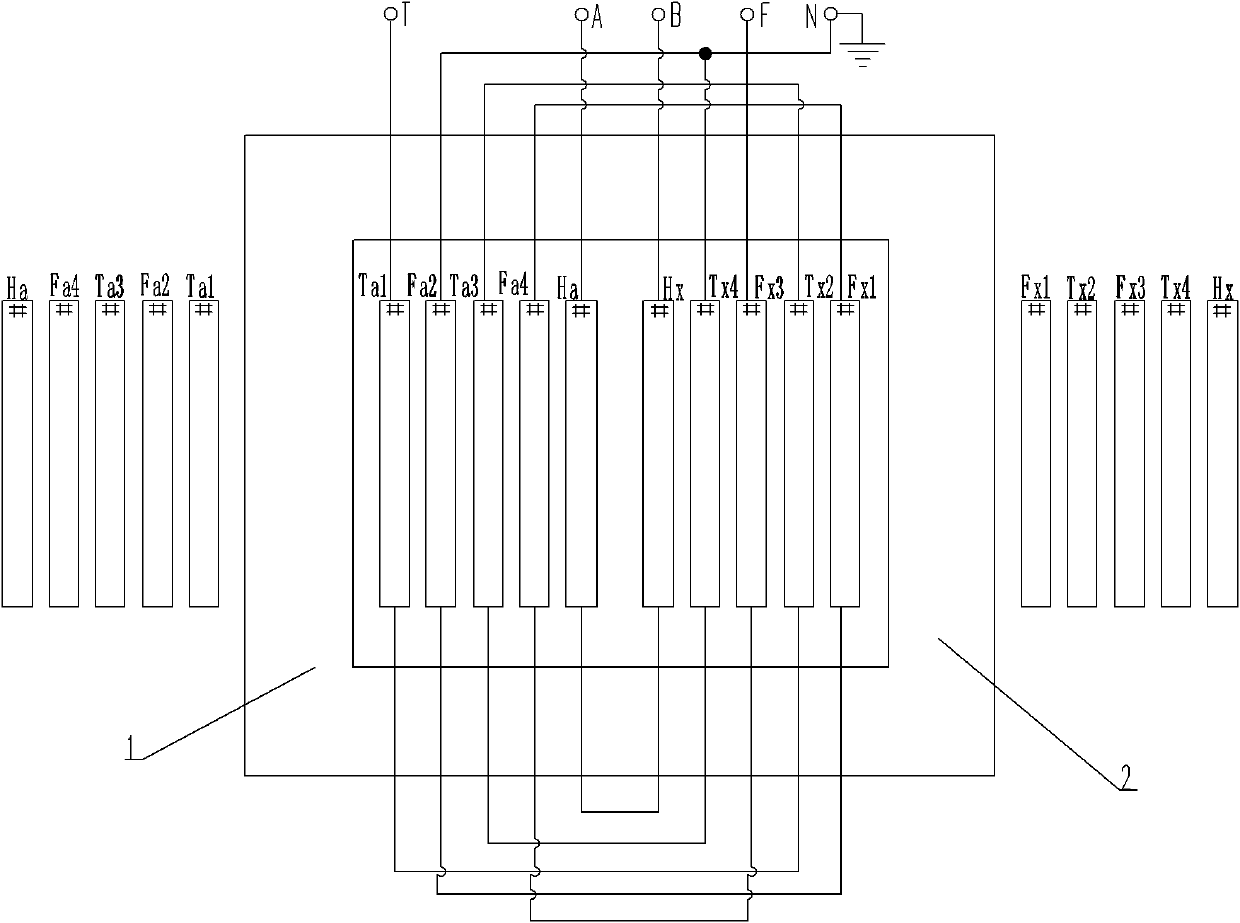

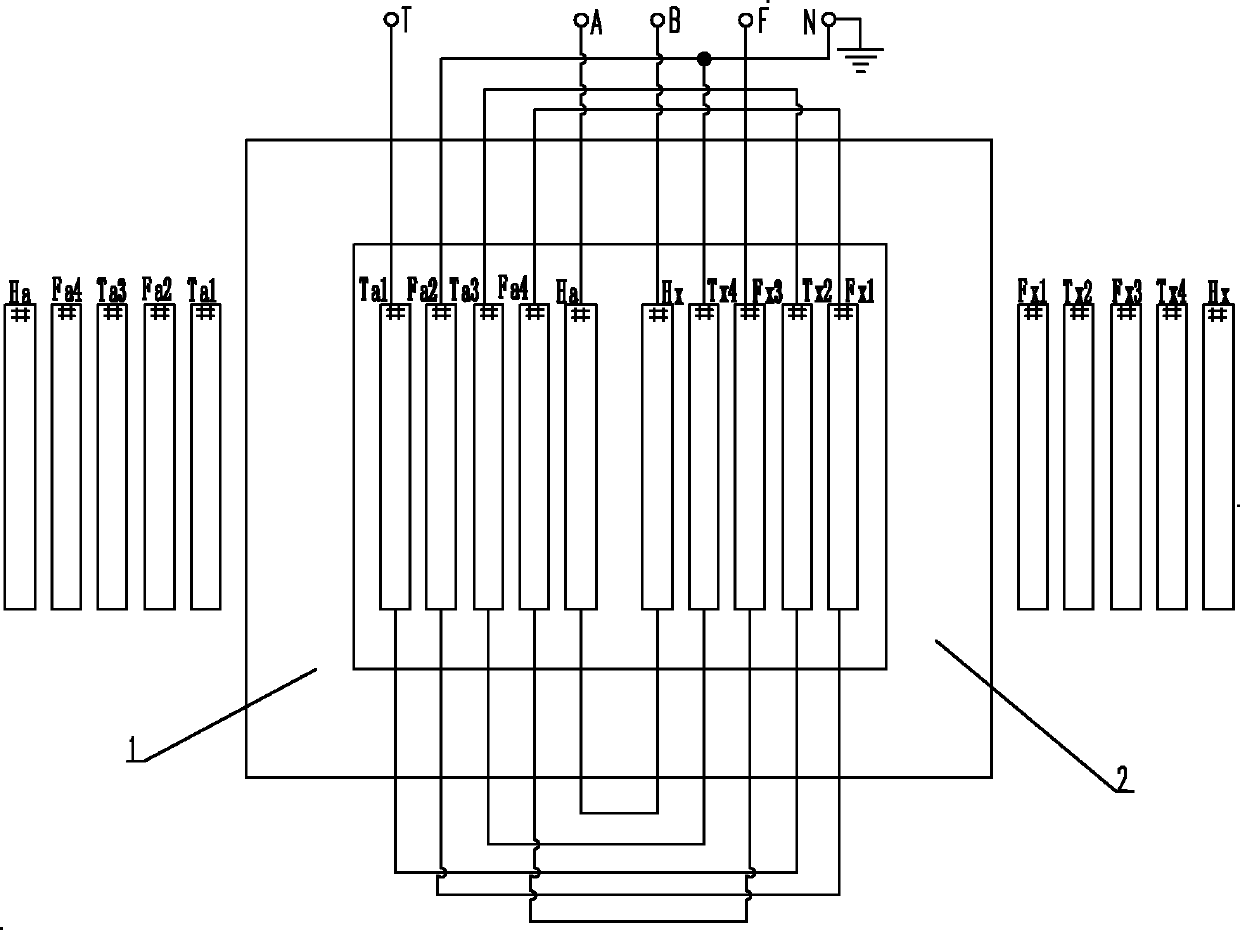

[0016] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0017] The transformer iron core of the present invention adopts a single-phase two-column structure iron core, including a core column group and a winding concentrically socketed on the iron core column, and the iron core column group includes a first iron core column 1, a second iron core Column 2, the iron core column is connected with five concentric winding layers from inside to outside, which are respectively the first winding layer, the second winding layer, the third winding layer, the fourth winding layer, and the fifth winding layer; wherein the first iron core The first winding layer of column 1 is the first winding Ta1 on the power supply side, the second winding layer is the second winding Fa2 on the feeding side, the third winding layer is the third winding Ta3 on the power supply side, and the fourth winding layer is th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com