Sensor distribution method for bowstring arc bridge structure made of special-shaped steel tube concrete

A technology for tied arch bridges and special-shaped steel pipes, which is applied in the fields of instruments, special data processing applications, and electrical digital data processing. Requirements for the safety assessment of complex structures, the inability to accurately analyze the local stress state, etc., to achieve the effect of ensuring robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

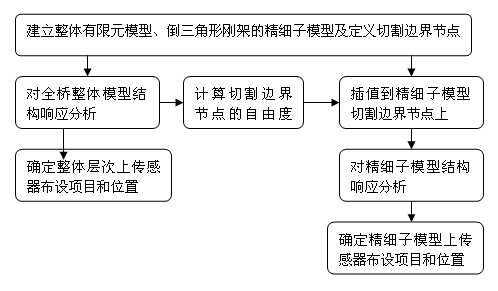

[0031] The sensor layout method for the special-shaped steel pipe concrete tied arch bridge structure of the present invention comprises the following steps:

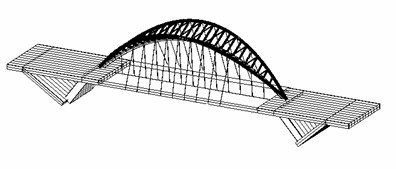

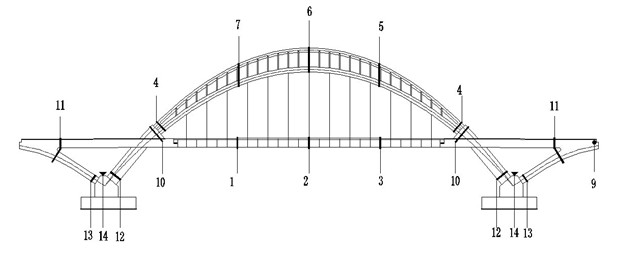

[0032] 1) According to the special-shaped concrete-filled steel tube tied arch bridge structure, the general finite element program is used to establish the overall finite element model of the whole bridge structure and the fine sub-model of the inverted triangular rigid frame, and define the inverted triangular rigid frame in the overall finite element model of the full bridge structure Cutting boundary nodes of fine submodels;

[0033] 2) For the overall finite element model of the full bridge structure established in step 1), conduct the response analysis of the full bridge structure under the action of dead load and traffic load respectively, and then determine the vulnerability of the integral stressed members according to the results of the response analysis , and then determine the sensor layout items and sensor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com